Polyphenylene sulfide modified material and preparation method and application thereof

A modified material, polyphenylene sulfide technology, applied in the field of polyphenylene sulfide modified material and its preparation, can solve the problems of rough product surface, lower impact resistance, lower paint spraying effect of injection molding products, etc., to achieve rigidity and Improvement in performance such as appearance, improvement in performance such as rigidity and appearance, and the effect of facilitating industrial mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

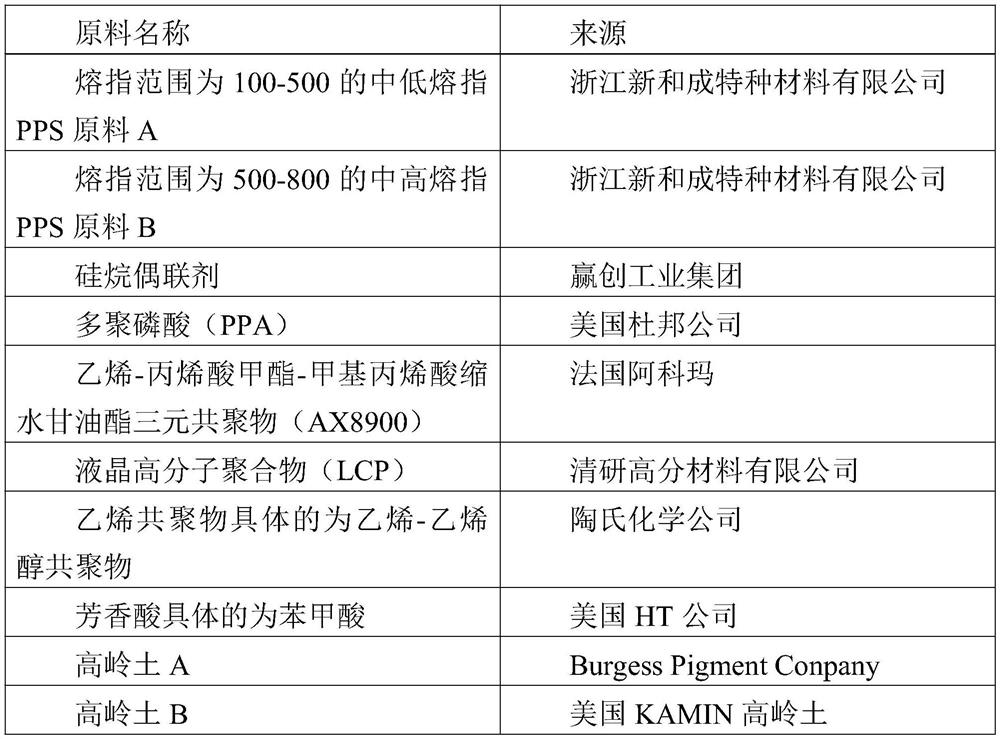

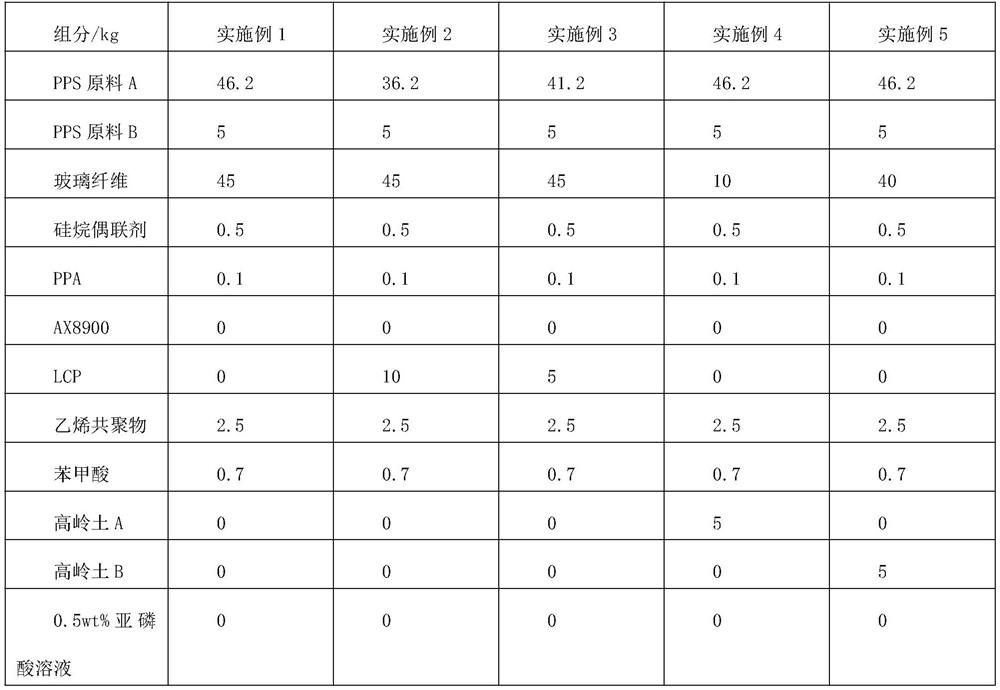

[0024] The preparation method of the preparation method of following embodiment and comparative example polyphenylene sulfide modified material comprises the steps:

[0025] S1: PPS raw material A for medium and low melting point, PPS raw material B for medium and high melting point, silane coupling agent, polyphosphoric acid, ethylene-methyl acrylate-glycidyl methacrylate terpolymer, liquid crystal polymer, Add ethylene copolymer, aromatic acid, kaolin, and 0.5wt% phosphorous acid solution into the mixer, the rotation speed of the large paddle of the mixer is 800r / min, the rotation speed of the small paddle is 800r / min, and the mixer runs for 4min to obtain a uniform mixture ;

[0026] S2: extrusion granulation: put the homogeneous mixture obtained in step S1 into an extruder for extrusion granulation, and at the same time side-feed glass fibers to obtain a composite material;

[0027] The processing parameters of the extruder are as follows: the rotational speed is 610r / min...

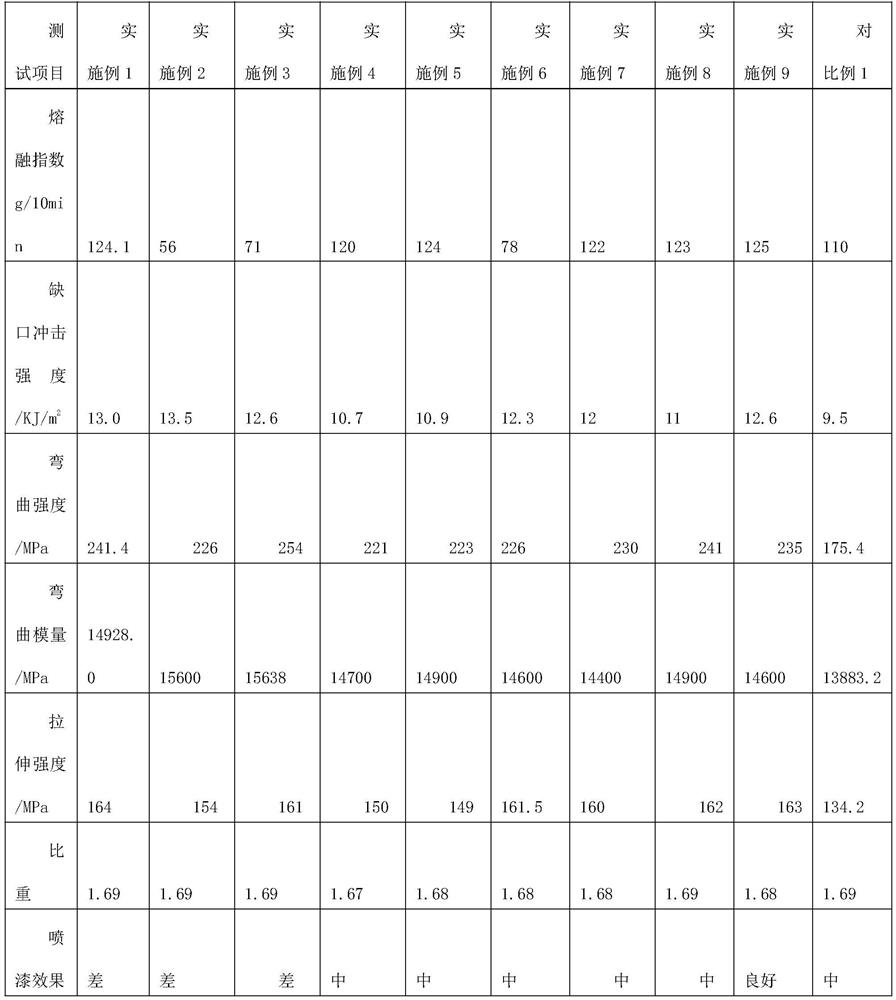

Embodiment 6-9

[0030] Table 2 implements the raw material composition of 6-9 polyphenylene sulfide modified materials

[0031] Component / kg Example 6 Example 7 Example 8 Example 9 PPS raw material A 43.2 46.2 46.2 46.2 PPS raw material B 5 5 5 5 glass fiber 43 45 43 43 A silane coupling agent 0.5 0.5 0.5 0.5 PPAs 0.1 0.1 0.1 0.1 AX8900 5 0 0 0 LCP 3 0 0 0 Ethylene copolymer 2.5 2.5 2.5 2.5 benzoic acid 0.7 3 3 0.7 Kaolin A 0 0 0 0 Kaolin B 2 2 2 2 0.5wt% phosphorous acid solution 0 0 3 3

[0032] In combination with Example 8 and Example 8 and Table 2, it can be seen that the other components except the 0.5wt% phosphorous acid solution total 100, and the addition amount of the 0.5wt% phosphorous acid solution is 3% of the sum of all other components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com