Air spring structure provided with auxiliary air chamber

A technology of adding air chambers and air springs, applied in the direction of springs, spring/shock absorbers, gas shock absorbers, etc., can solve the problems of attenuating vibration, not having the ability to adjust stiffness, absorb energy, etc., to improve efficiency and improve shock absorption Effect, effect of protection product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

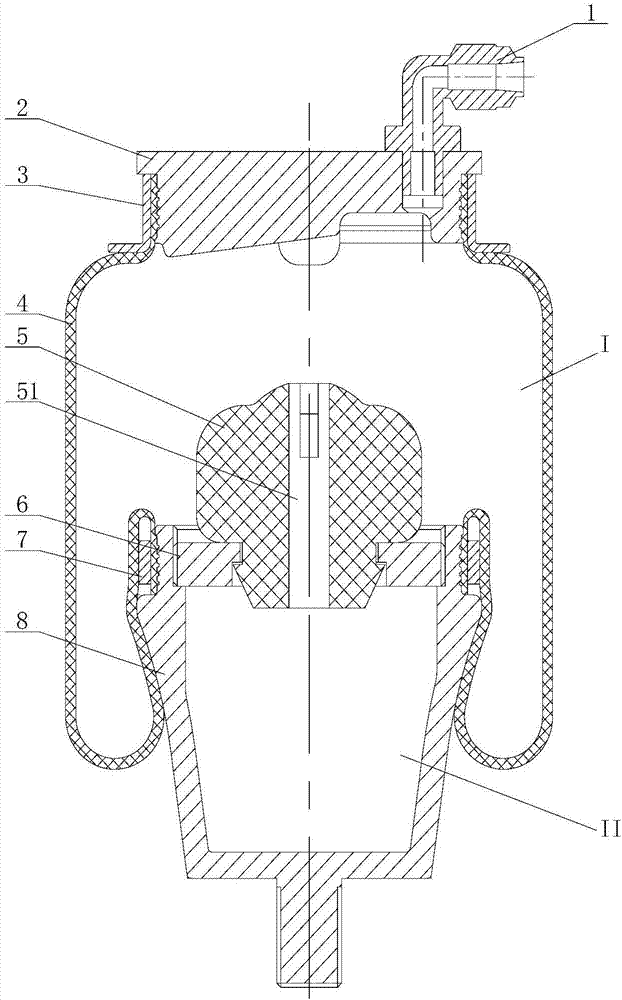

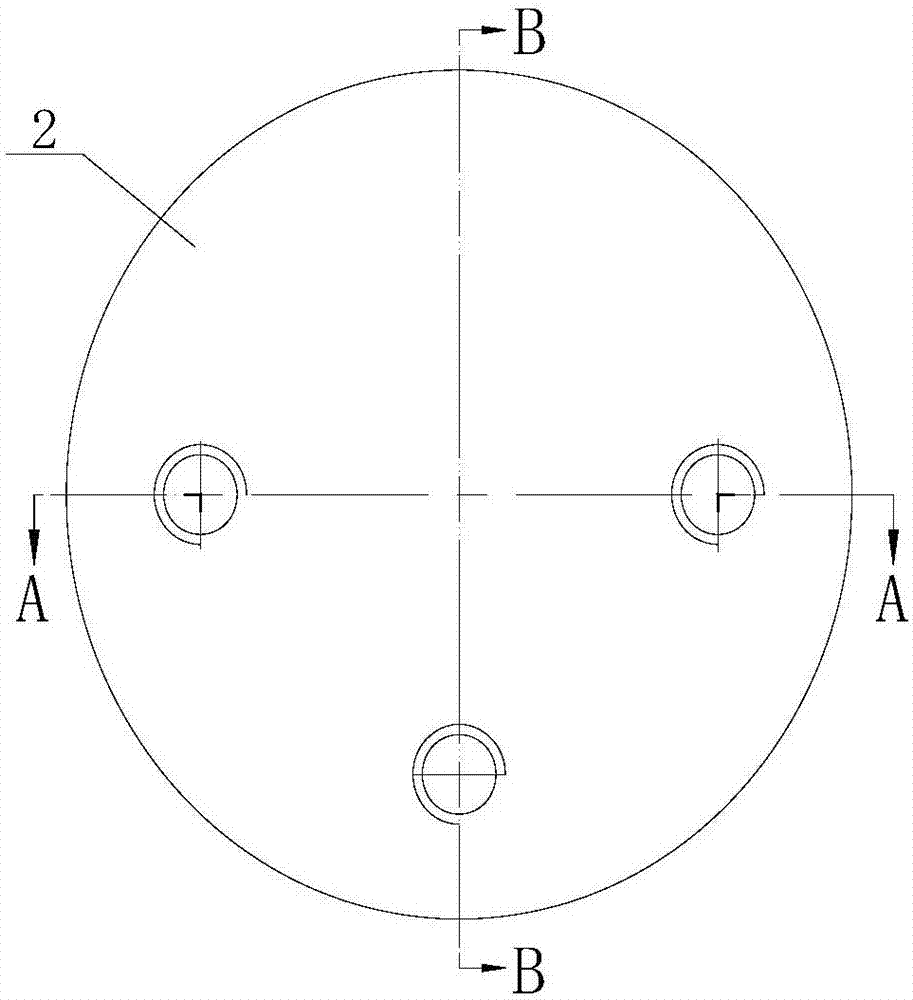

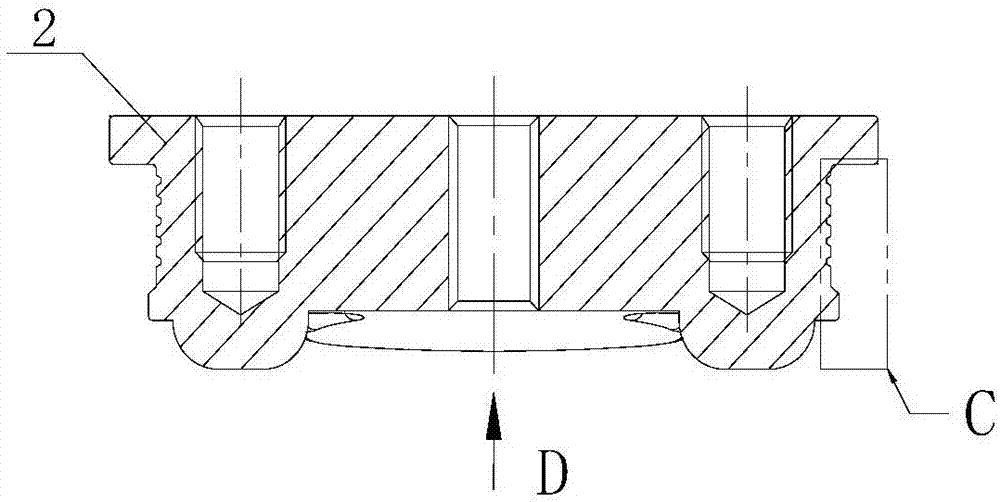

[0040] Such as figure 1 As shown, an air spring structure with an additional air chamber according to the present invention includes an upper cover 2, a flanged upper pressure ring 3, a rubber airbag body 4, a lower pressure ring 7, and a piston 8 connected in sequence. The upper opening of the rubber airbag body 4 is installed on the upper cover 2 through the flanged upper pressure ring 3 , and the top of the upper cover 2 is also provided with an air nozzle 1 . The lower end opening of the rubber air bag body 4 is installed on the piston 8 by the pressing ring 7, and the top of the piston 8 is also provided with a piston cover 6 (such as Figure 10 shown), the piston cover 6 is equipped with a buffer block 5, and the buffer block 5 separates the cavity formed by the rubber air bag body 4 and the piston 8 into the main air chamber 1 in the air bag and the additional part of the piston 5 inner chamber. As for the air chamber II, the volume ratio of the main air chamber I to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com