Small-equivalent waste propellant flash burning treatment device

A technology of waste gunpowder and treatment device, applied in blasting and other directions, can solve the problems of high degree of danger, incineration waste gas cannot be collected, etc., to achieve the effect of ensuring safety and solving safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention provides a small-equivalent waste gunpowder flash burning treatment device, which realizes a single feeding of 200-300g and a maximum daily processing capacity of 50-80kg through automatic feeding and remote ignition, which can ensure the incineration and removal of waste gunpowder The rate is above 99%.

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

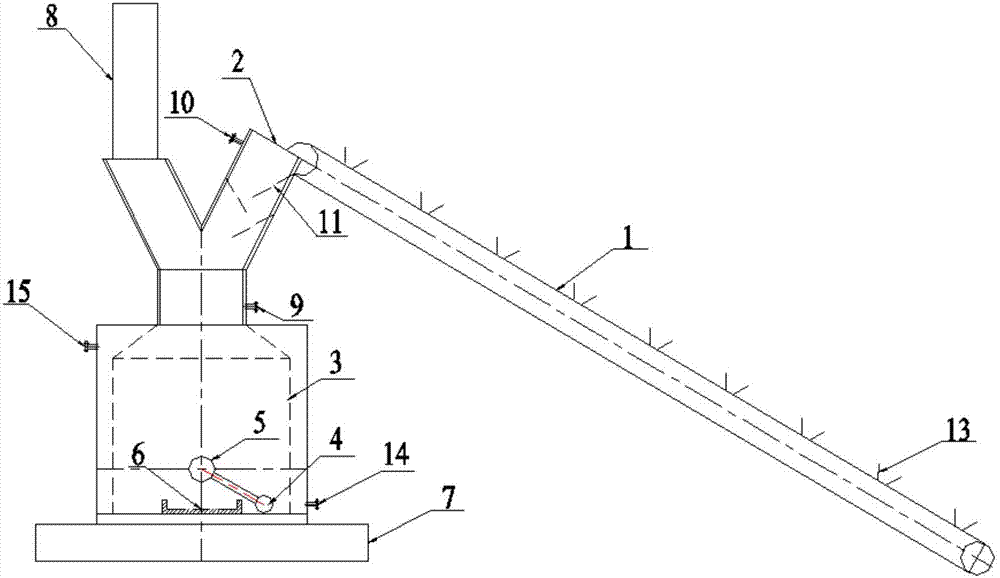

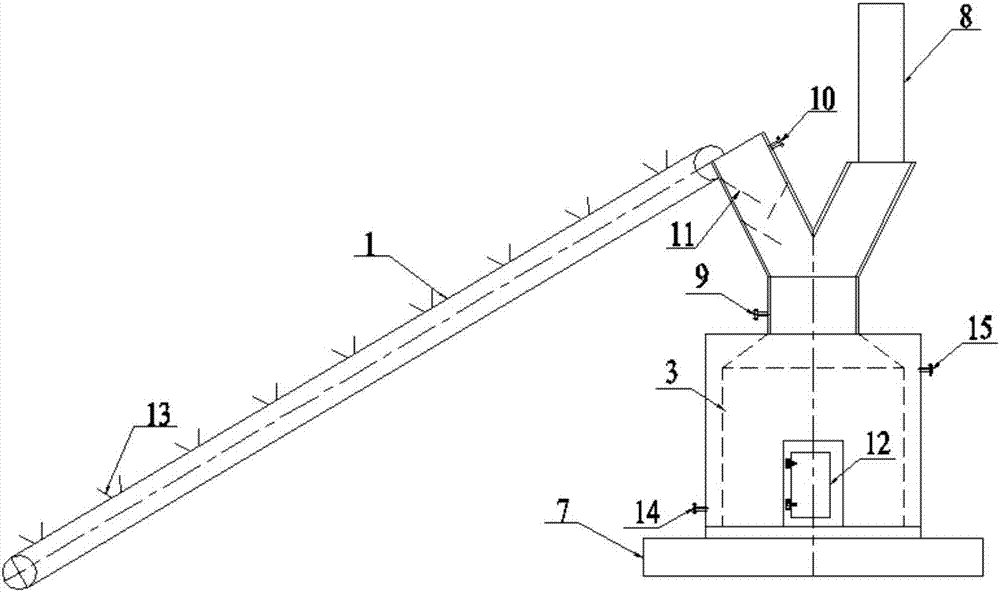

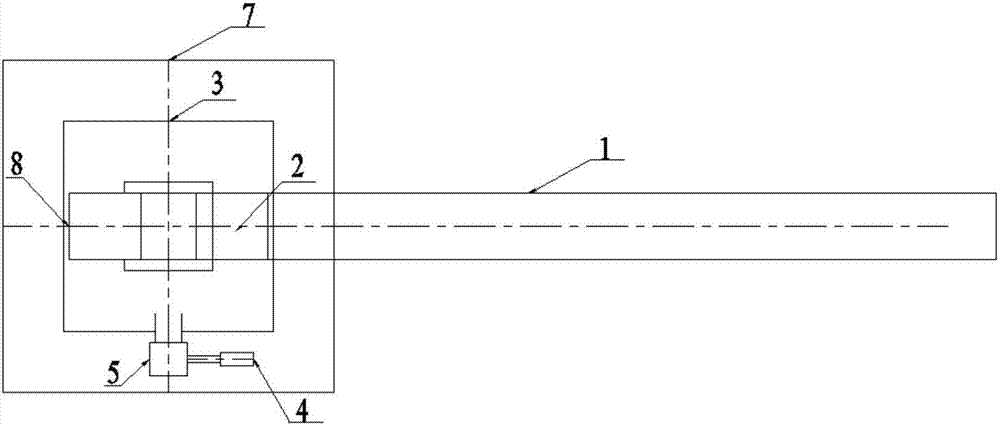

[0025] Take the destruction of waste double-base propellants as an example, such as figure 1 , 2 , 3, a kind of small-equivalent waste gunpowder flashing treatment device that the present invention relates to mainly includes feeding conveying device 1, incinerator body 3, air compressor 4, igniter 5, incineration tray 6, base 7, single To the shut-off valve 11, the armored door 12.

[0026] The working process of the small-equivalent waste gunpowder flash burning treatment device is as follows: manually put 150g of doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com