Safety device and method for disassembling and assembling bird repellent device in electrified manner

A technology of safety device and bird repellent, applied in the direction of overhead line/cable equipment, etc., can solve the problems of hidden safety hazards, complicated operation, lack of fixation, etc., and achieve the effect of safe disassembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

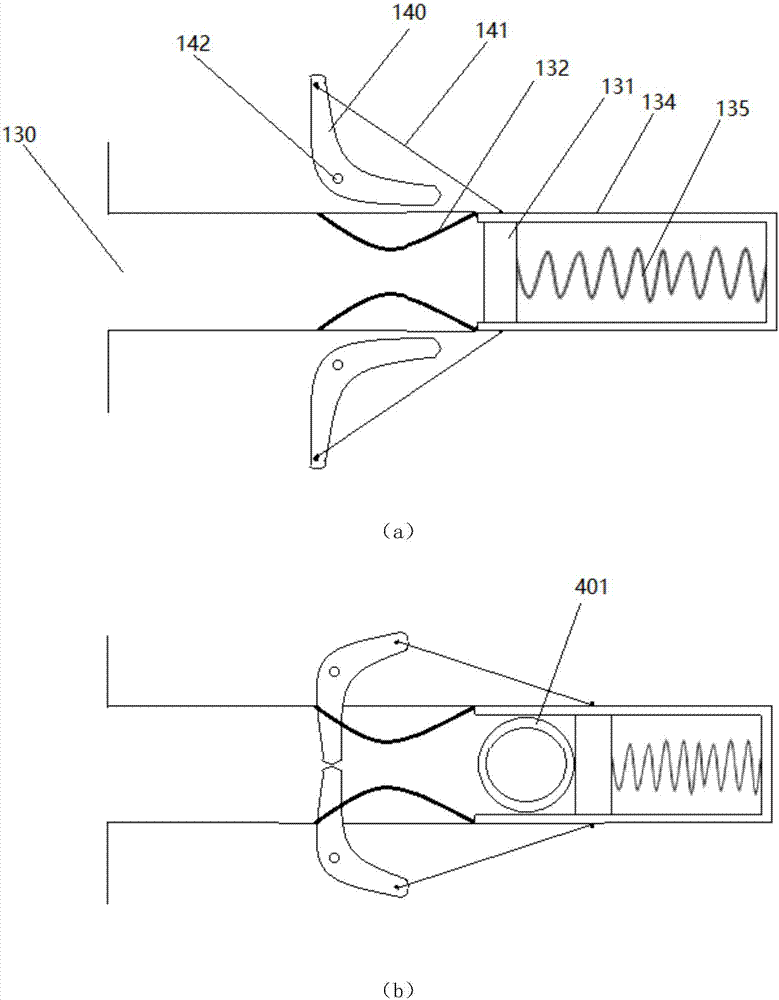

[0048] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail in conjunction with the accompanying drawings. This description presents, by way of illustration and not limitation, specific embodiments consistent with the principles of the invention in sufficient detail to enable those skilled in the art to practice the invention without departing from this disclosure. Other embodiments may be utilized and the structure of elements may be changed and / or substituted within the scope and spirit of the invention. Accordingly, the following detailed description should not be read in a limiting sense.

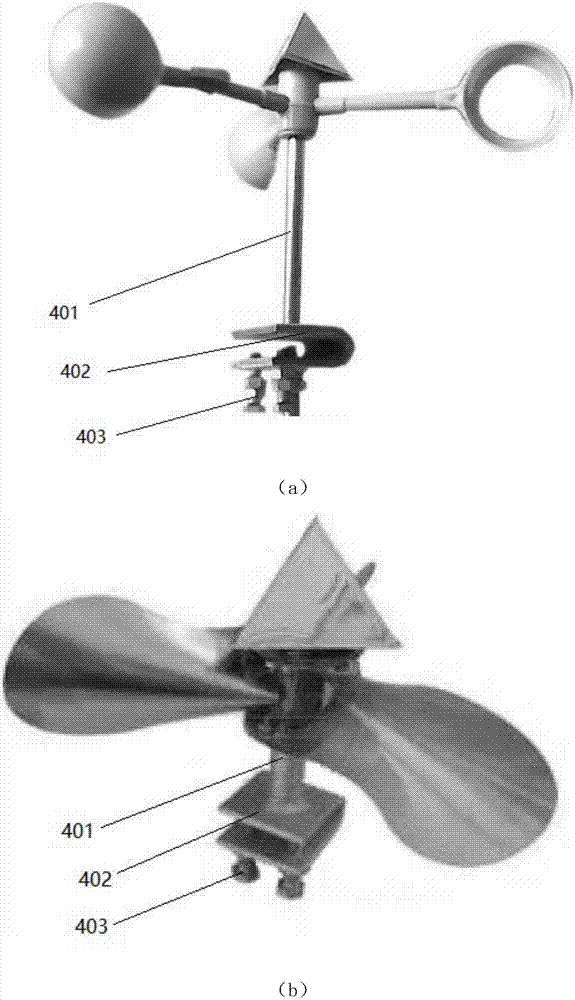

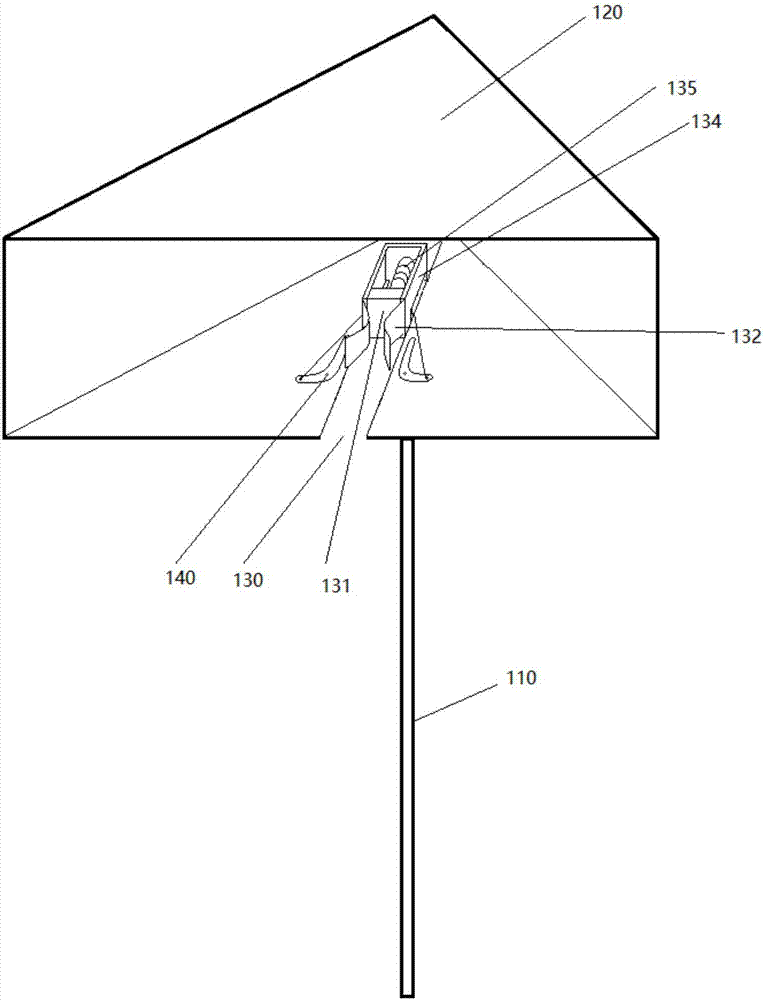

[0049] Such as figure 2 As shown, the present invention provides a live detachable bird repellent safety device, the bird repellent includes a bird repellent mechanism and a bracket, and the bracket includes a support rod 401 and a bracket seat 402, wherein one end of the support ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com