Housing structure for totally enclosed blade server

A blade server, fully enclosed technology, applied in the direction of server, support structure installation, electrical equipment structural parts, etc., can solve the problems of failure, insufficient heat dissipation, and performance degradation of electronic equipment, etc. body shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

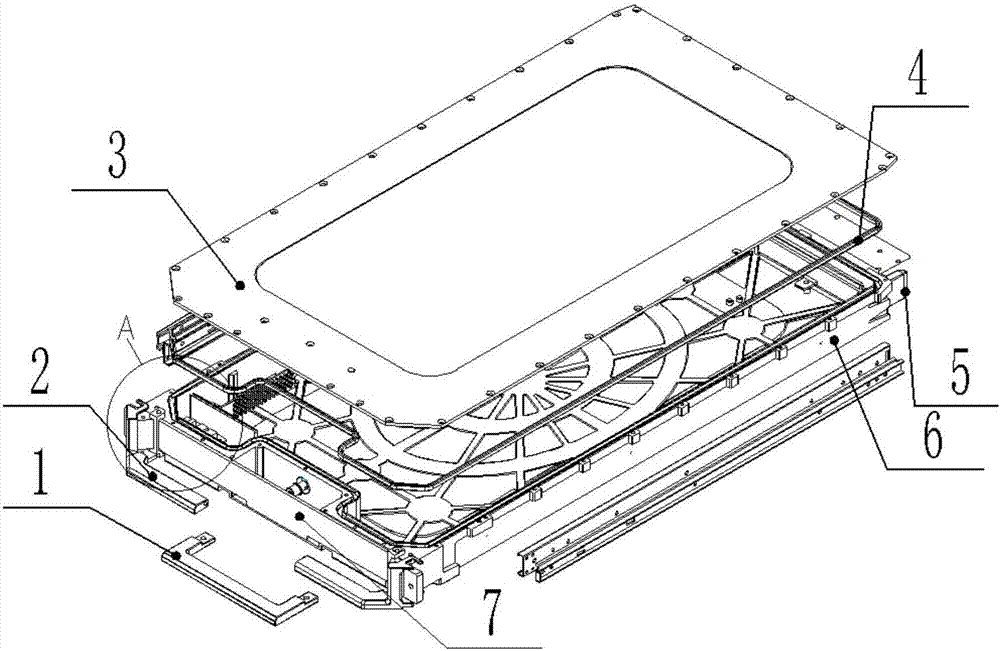

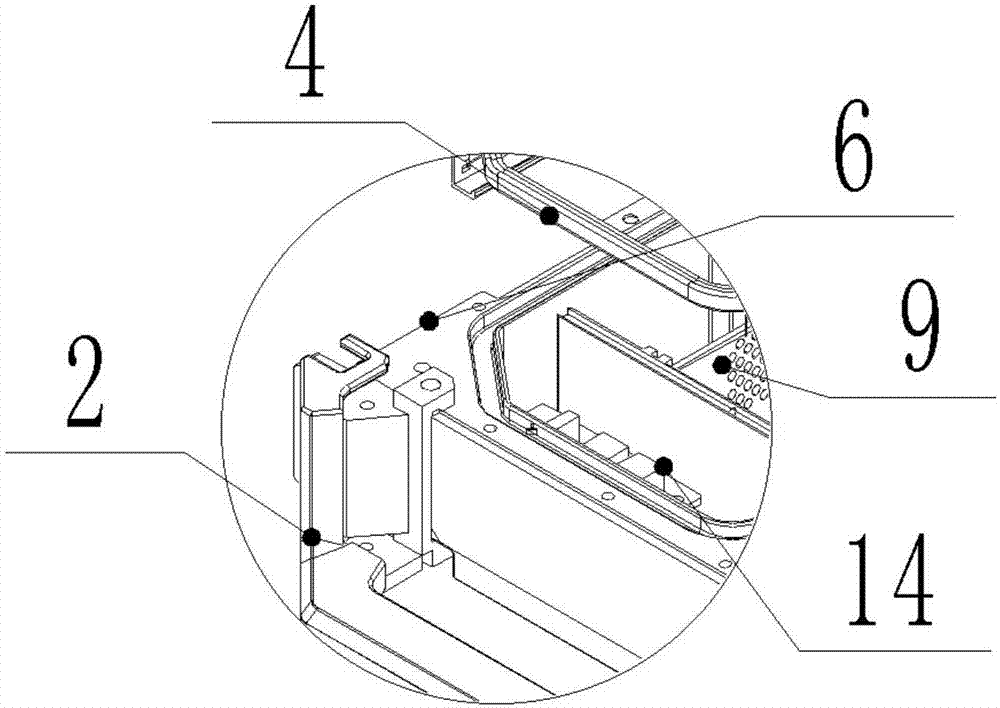

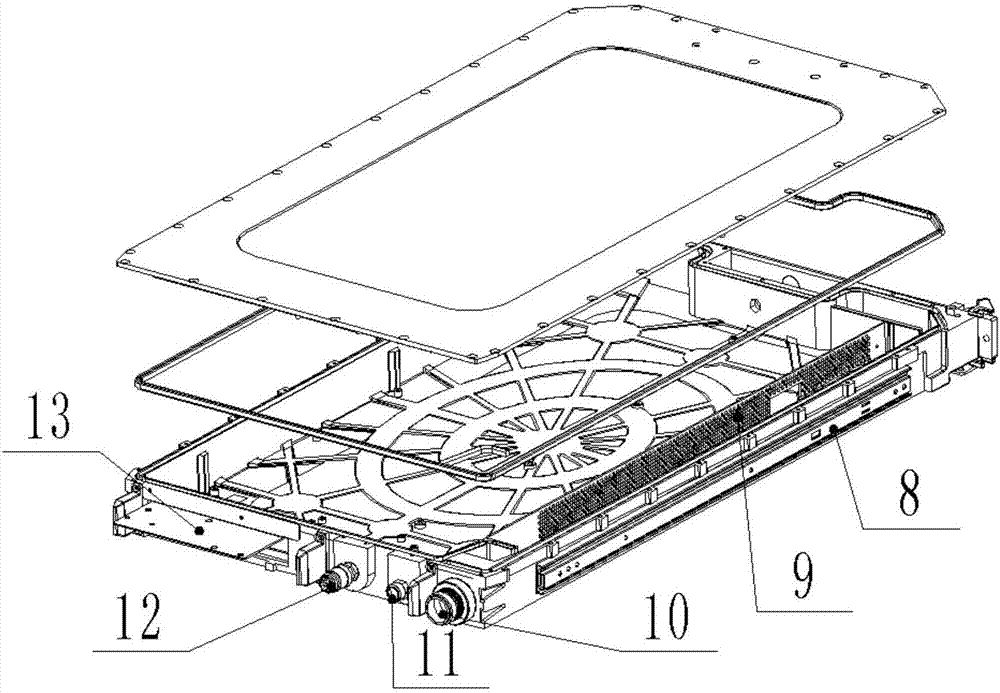

[0019] now refer to Figure 1 to Figure 4 The present invention is described in detail. It should be understood that the following descriptions are only examples of the present invention and do not constitute any limitation to the present invention. Various embodiments can be combined with each other to form other embodiments not described below or shown in the drawings.

[0020] refer to Figure 1 to Figure 4 , according to one embodiment of the present invention, a casing structure for a fully enclosed blade server is provided, including: a casing 6 including a front end, a rear end, and opposite side walls connecting the front end and the rear end ; The air outlet valve 10 and the liquid inlet valve 12 are respectively arranged at the rear end; and the pressure regulating valve 11 and the liquid level sensor module 14, the pressure regulating valve 11 is arranged at the rear end, and the liquid level sensor module 14 is arranged in the housing 6 And it is electrically co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com