Server cabinet

A server and chassis technology, which is applied in the direction of servers, data centers, cooling/ventilation/heating transformation, etc., can solve the problems of loose fastening of the upper cover and the shell, and lower parallelism of the upper cover, so as to achieve easy implementation and prevent cold The effect of preventing liquid overflow, ensuring airtightness and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

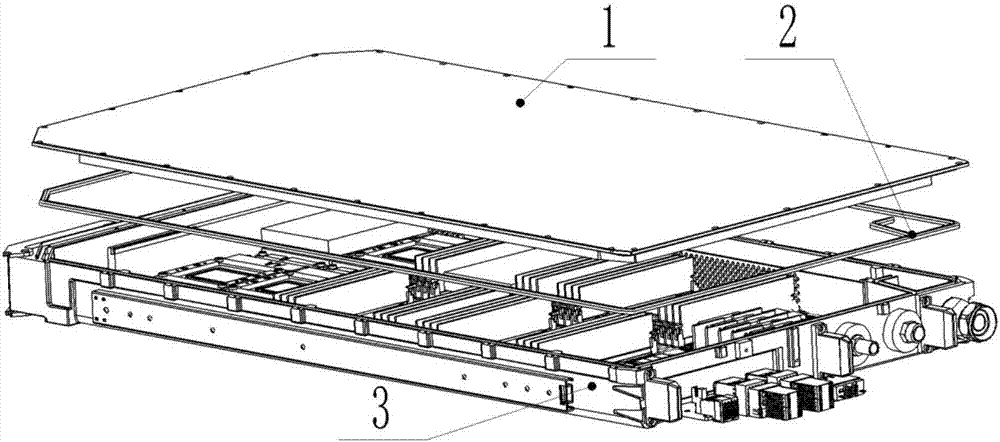

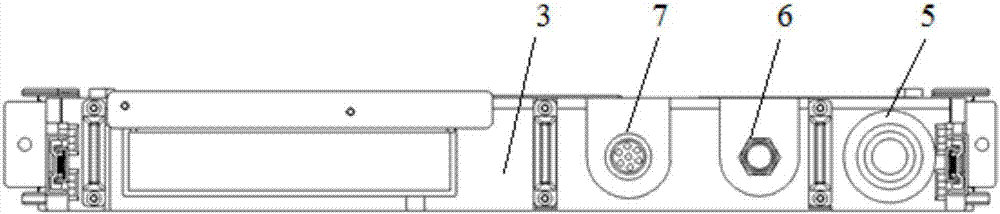

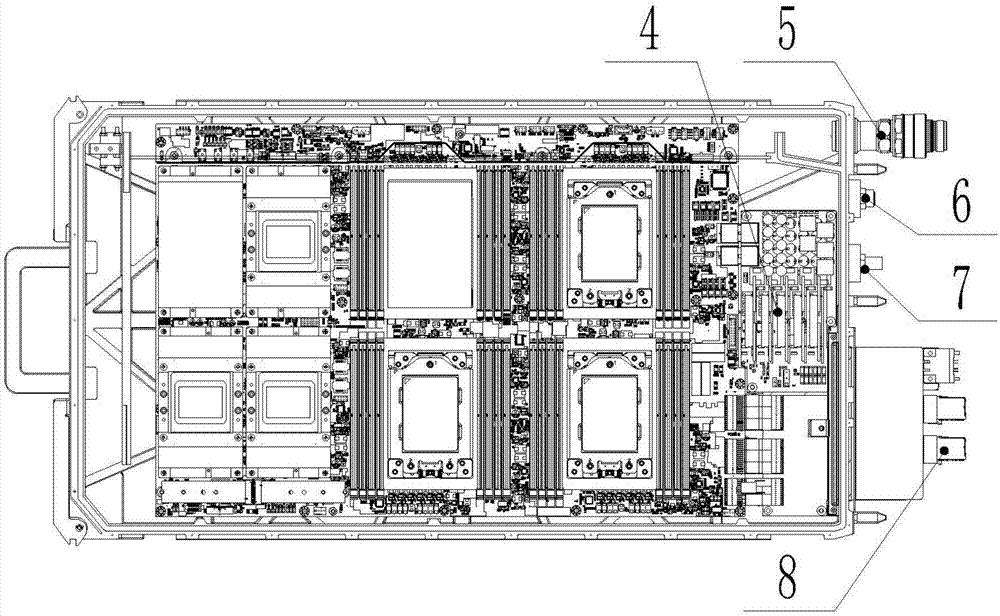

[0027] The invention will now be described with reference to the accompanying drawings. Such as Figure 1 to Figure 9 As shown, the present invention provides a server case, which includes a casing 3 and an upper cover 1 detachably connected to the casing 3 , wherein the upper cover 1 and the casing 3 are in a sealed connection. Further, the server case further includes an air outlet valve 5 , a pressure regulating valve 6 and a liquid inlet valve 7 , which are respectively arranged on the casing 3 and are sealedly connected with the casing 3 . In addition, the server chassis also includes a high-voltage DC board 4 and a switching module 8, the switching module 8 is installed on the high-voltage DC board 4, and the high-voltage DC board 4 is arranged in the housing 3, the switching module 8 is located outside the housing 3 and It is tightly connected with the shell 3.

[0028] Therefore, in the provided server case, the upper cover 1 and the housing 3 are hermetically connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com