Micro rectangular multi-core connector with air-tight seal and manufacturing method thereof

An airtight, micro-rectangular technology, applied in the direction of connection, parts of the connection device, electrical components, etc., can solve the problems of product air leakage failure, high integration density, glass cracking, etc., to ensure airtightness and reliability, Good process compatibility and reduced packaging volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

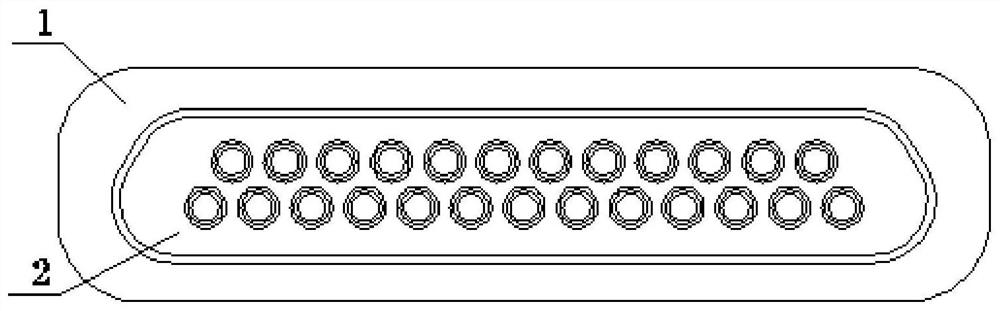

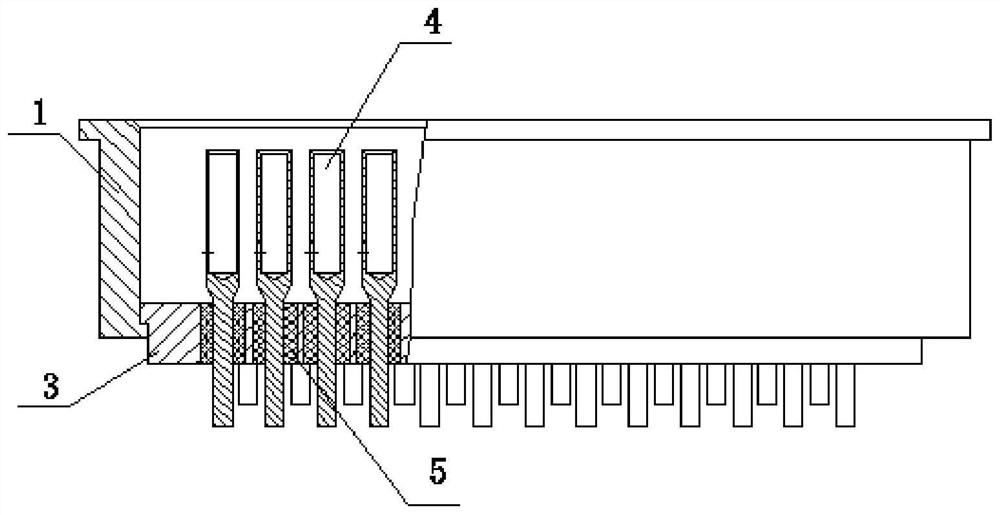

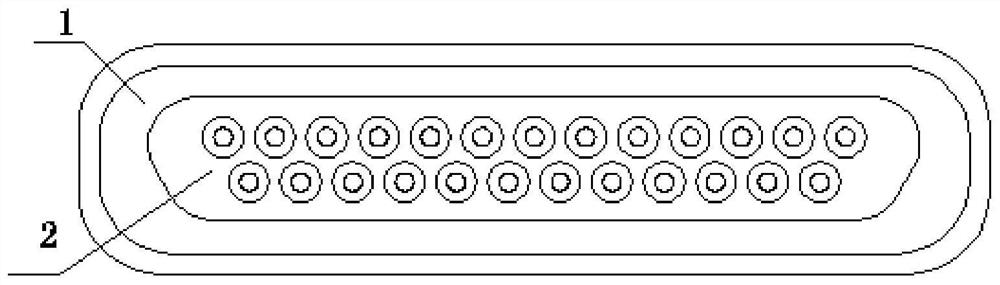

[0027] Such as figure 1 , figure 2 with image 3 As shown, the present invention provides a micro-rectangular multi-core connector with airtightness, including a shell 1, an airtight socket 2; the airtight socket includes a pin 4, an insulating medium 5 and an adapter plate 3, the The adapter plate 3 is provided with an array of through holes and a boss structure, and the pins are sintered side by side in the through holes of the adapter plate 3. The insulating medium 5 is filled between the pins 4 and the adapter plate 3 to form an air-tight socket. 2 The boss structure on the upper part of the adapter plate 3 is positioned inside the shell 1, and is fixed and sealed with the shell 1 by brazing; the difference between the thermal expansion coefficient of the insulating medium and the thermal expansion coefficient of the adapter plate does not exceed 2ppm / °C.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com