Wheel type independent suspension system of mine resistant and ambush protected vehicle

A suspension system and independent suspension technology, which is applied in the field of independent suspension system of wheeled anti-mine anti-ambush vehicles, can solve the problem of not fully meeting the technical requirements of wheel-type anti-mine anti-ambush vehicles and the overall situation of wheeled anti-mine anti-ambush vehicles. Problems such as difficulty in layout and reduction of the internal space of the wheeled mine-resistant ambush vehicle achieve the effects of reducing vibration, improving off-road performance, and increasing ground clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

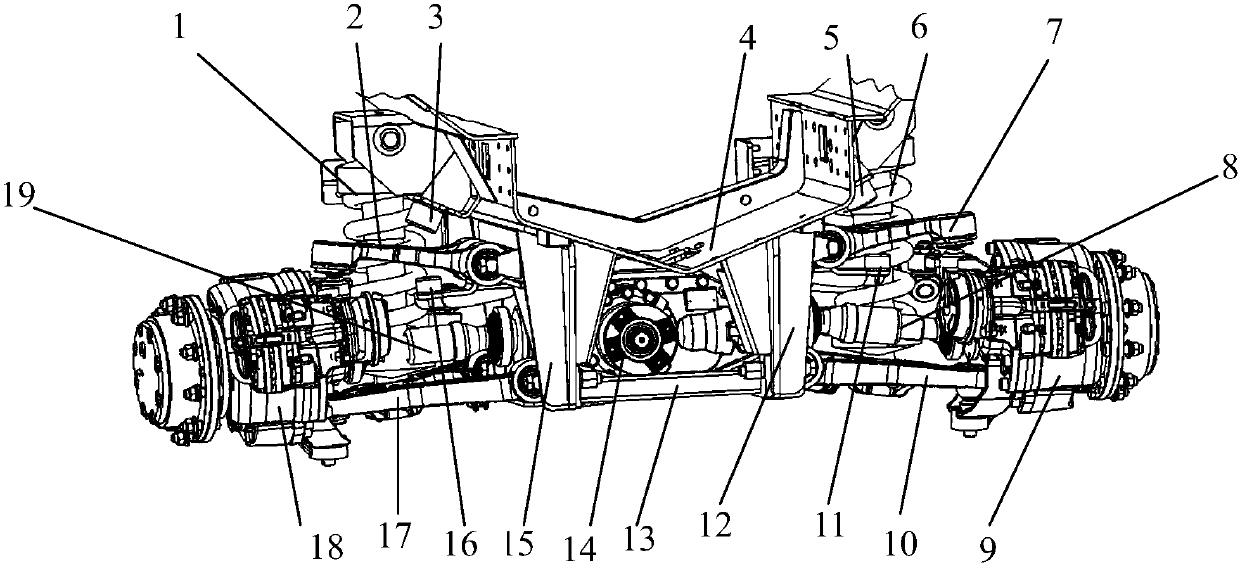

[0023] The independent suspension system of the wheeled mine anti-ambush vehicle involved in this embodiment includes a left front suspension system, a right front suspension system, a left rear suspension system, a right rear suspension system; a left front suspension system and a right front suspension system The structure is symmetrical, the left rear suspension system and the right rear suspension system are structurally symmetrical; the left rear suspension system and the right rear suspension system have the same structure as the left front suspension system and the right front suspension system, except that the stiffness of the coil spring is slightly different; Now focus on the structure of the left front suspension system.

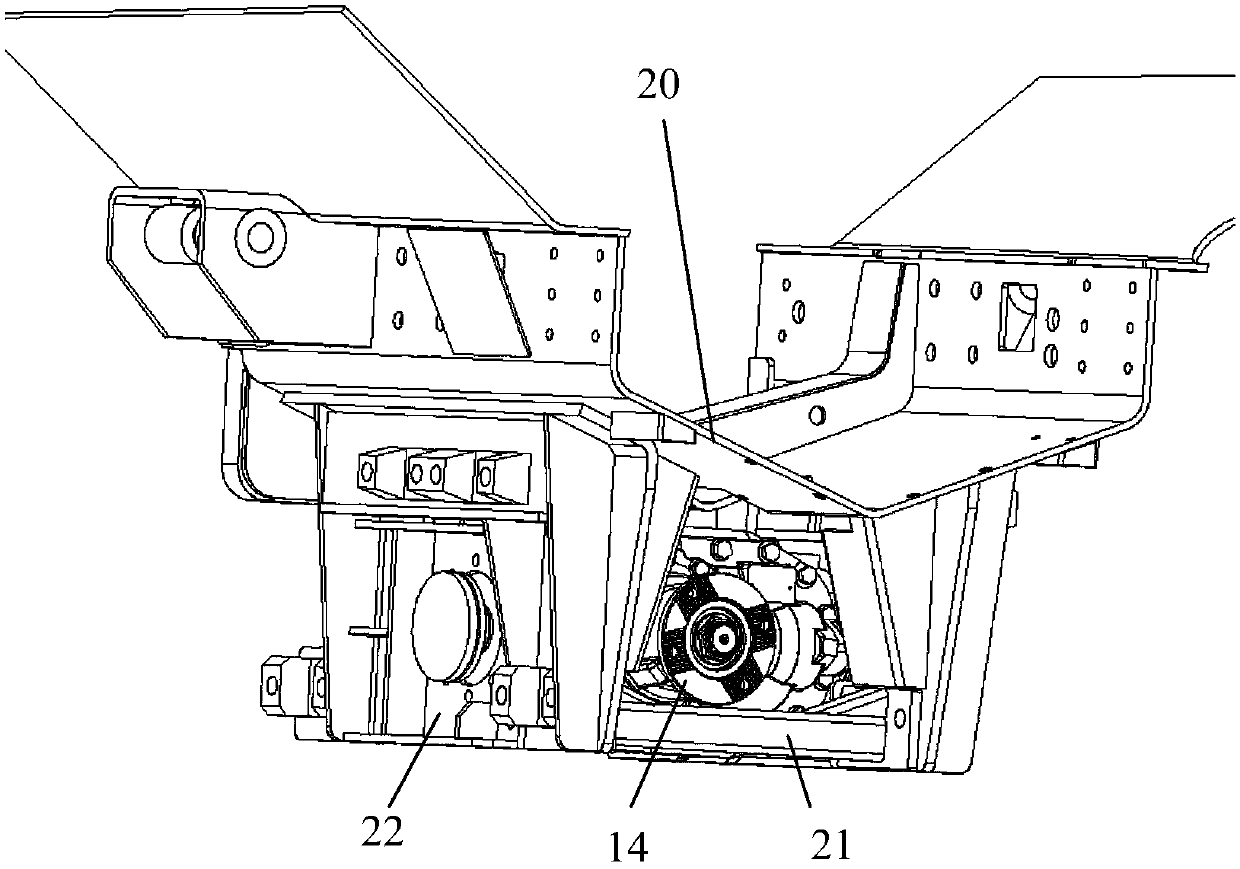

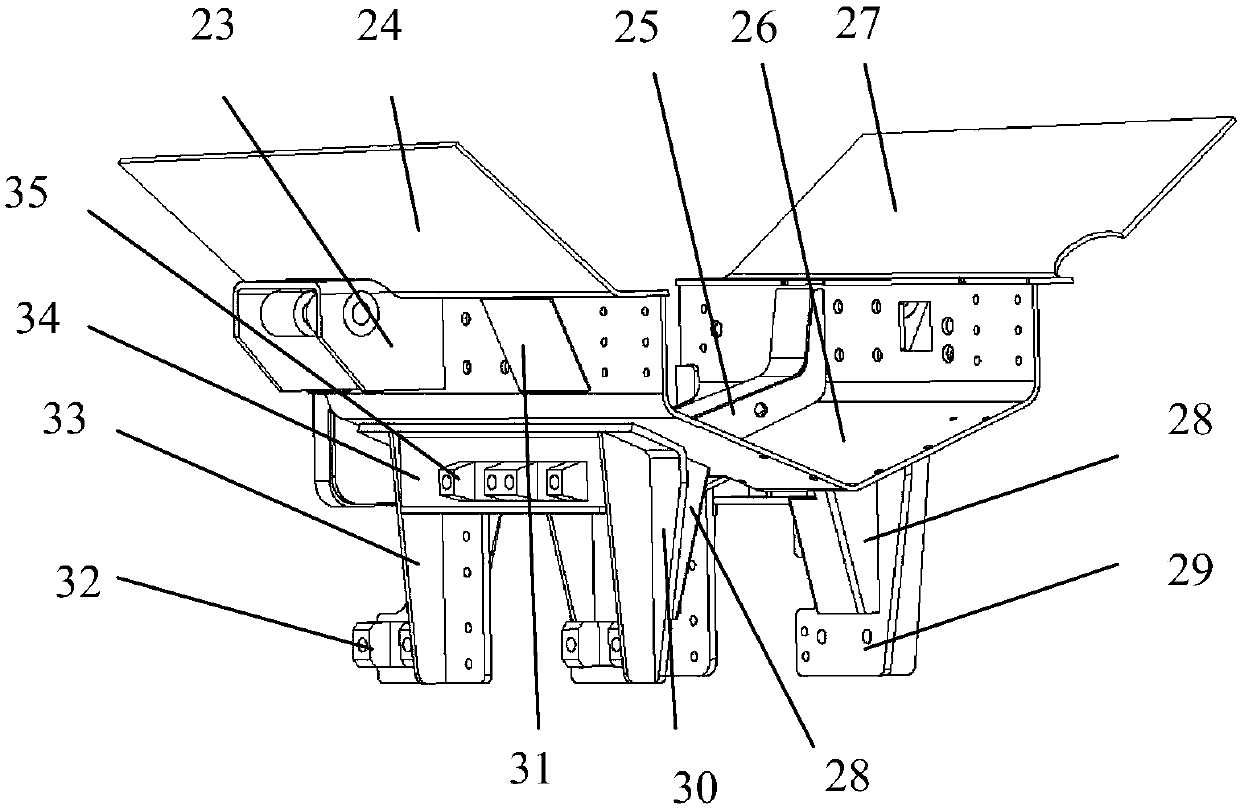

[0024] Such as figure 1 As shown, the left cross arm mounting bracket welding assembly 15 and the right cross arm mounting bracket welding assembly 12 are welded under the V-shaped car body welding assembly 4. In order to increase the strength of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com