Heavy-duty vehicle parallel double tire quarter active suspension simulation test bench

An active suspension, heavy-duty vehicle technology, applied in vehicle suspension/shock absorption mechanism testing, etc., can solve problems such as inability to meet test requirements, ignoring interactions, and single test function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

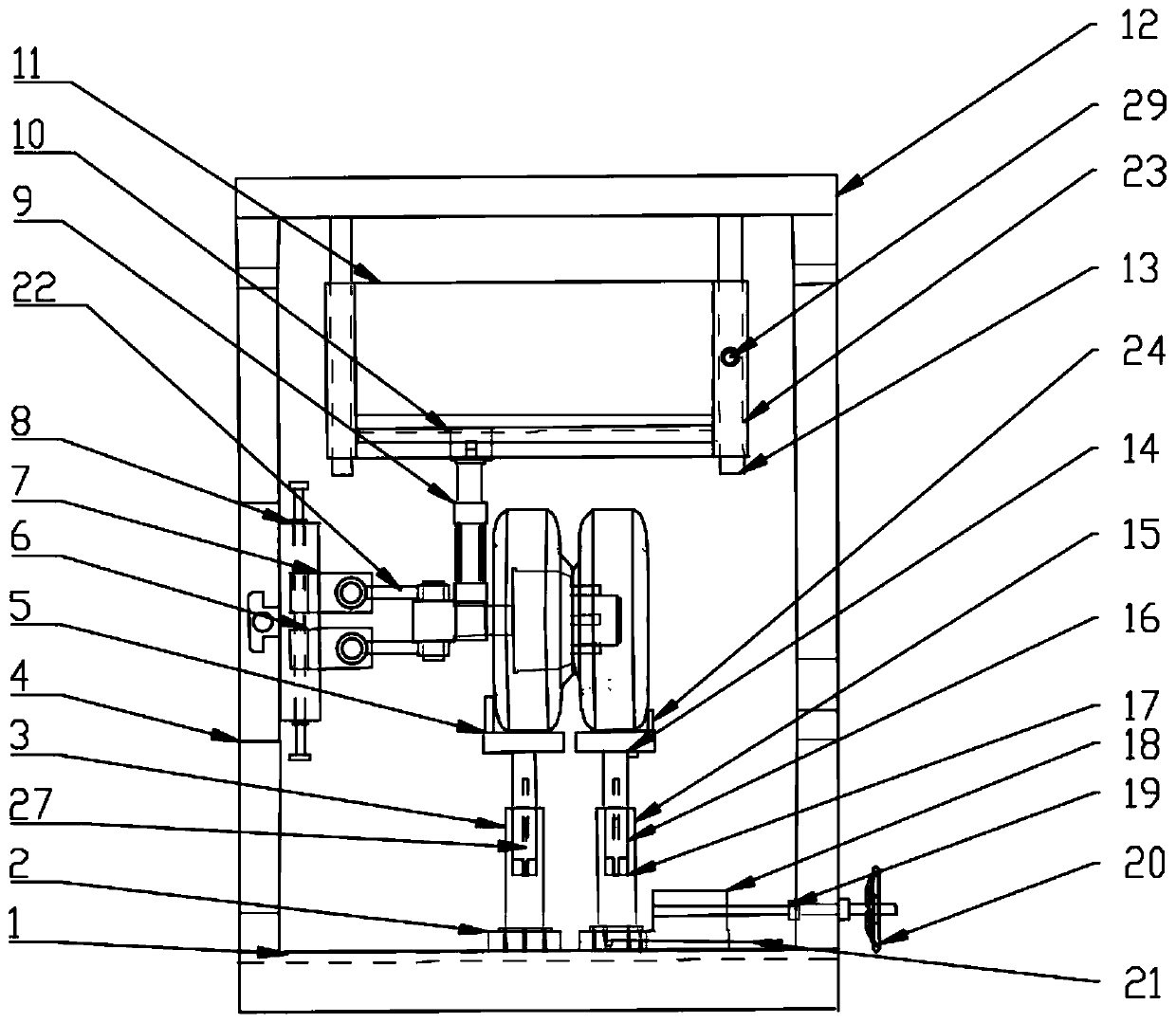

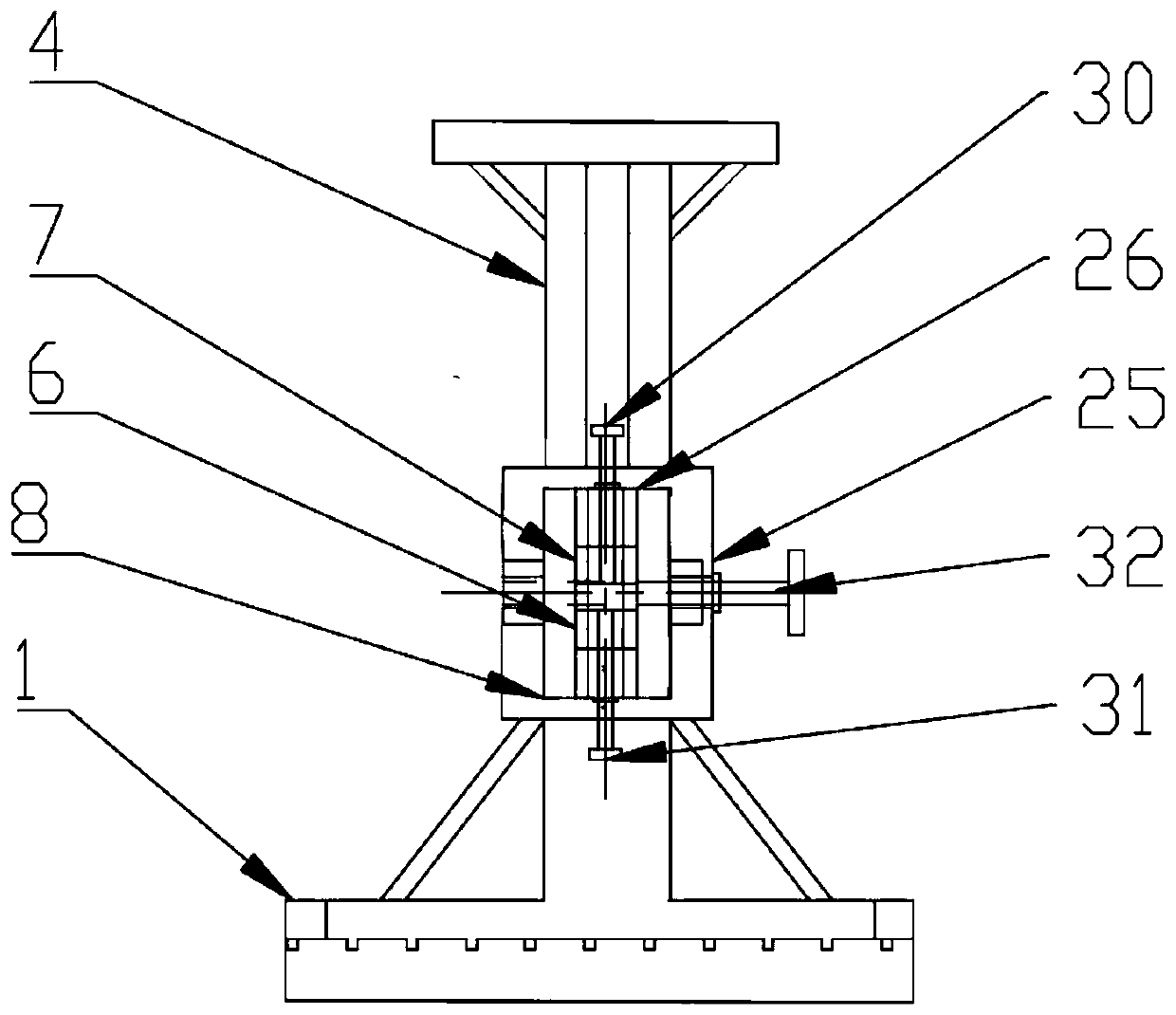

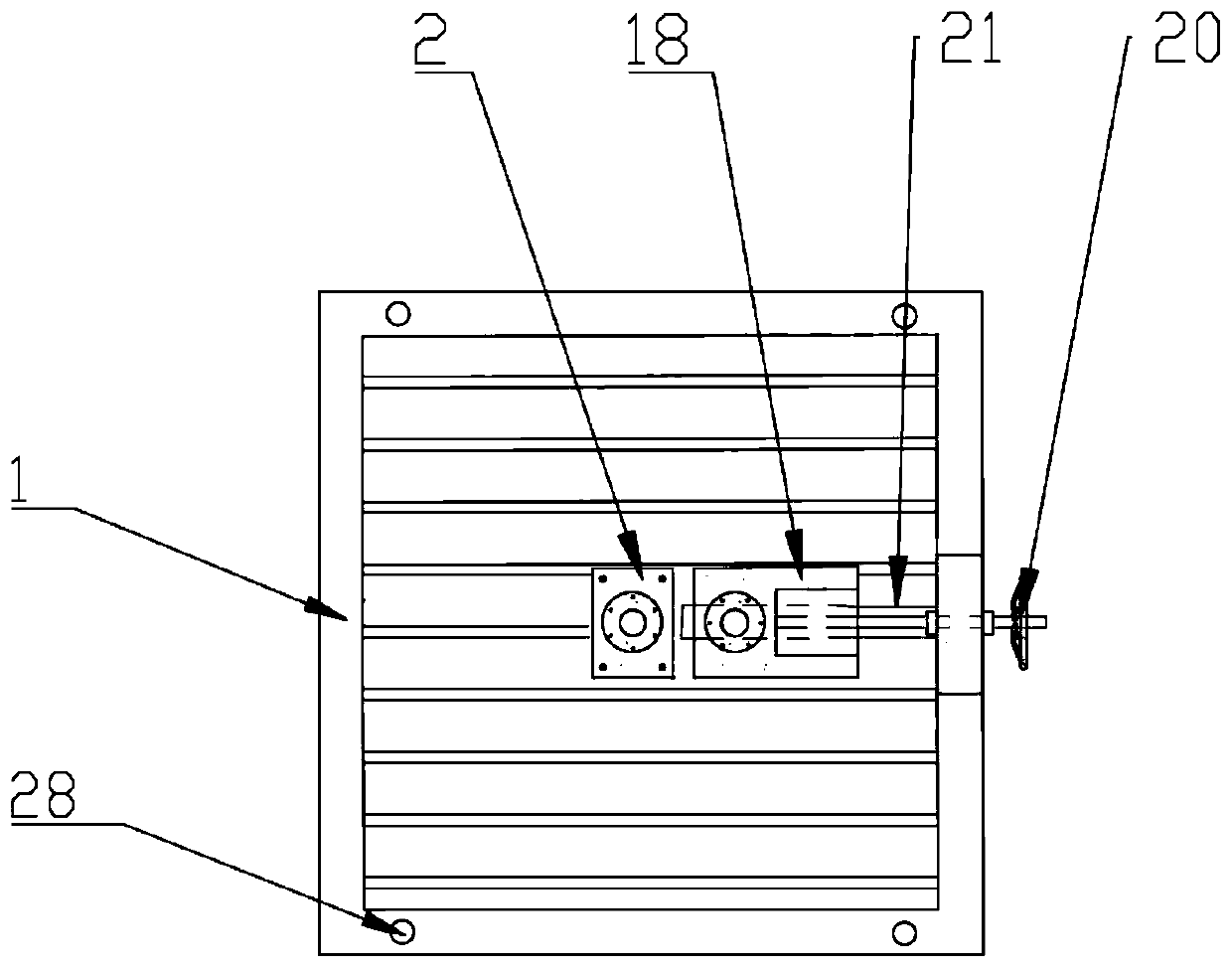

[0022] exist figure 1 In the schematic diagram of the front view of the working state of the heavy-duty vehicle parallel double tire quarter active suspension simulation working condition test bench, the base 1 fixed and installed on the horizontal iron by strong bolts 28 is provided with a bracket assembly ,Such as figure 2 As shown, two opposite lower ends of the base are provided on both sides of the side brackets 4 vertically connected to them, and the upper ends of the two brackets are provided with connecting plates 12 to form the frame of the test bench. A horizontal trapezoidal groove 25 is provided on the position corresponding to the working disk inside the left side bracket, and a fixture platform lead screw 32 is installed on one side of the horizontal trapezoidal groove. One side) corresponding to the set trapezoidal slide block, horizontal trapezoidal groove 25 one ends are fixedly installed with the leading screw 32 of band handwheel, and leading screw other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com