Performance detection system and detection method for rotary valve actuator

A valve actuator and detection method technology, applied in the testing of machine/structural components, testing of mechanical components, instruments, etc., can solve the problems of lack of versatility and integrity, inability to perform effective verification, singleness, etc., and achieve a The effect of versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

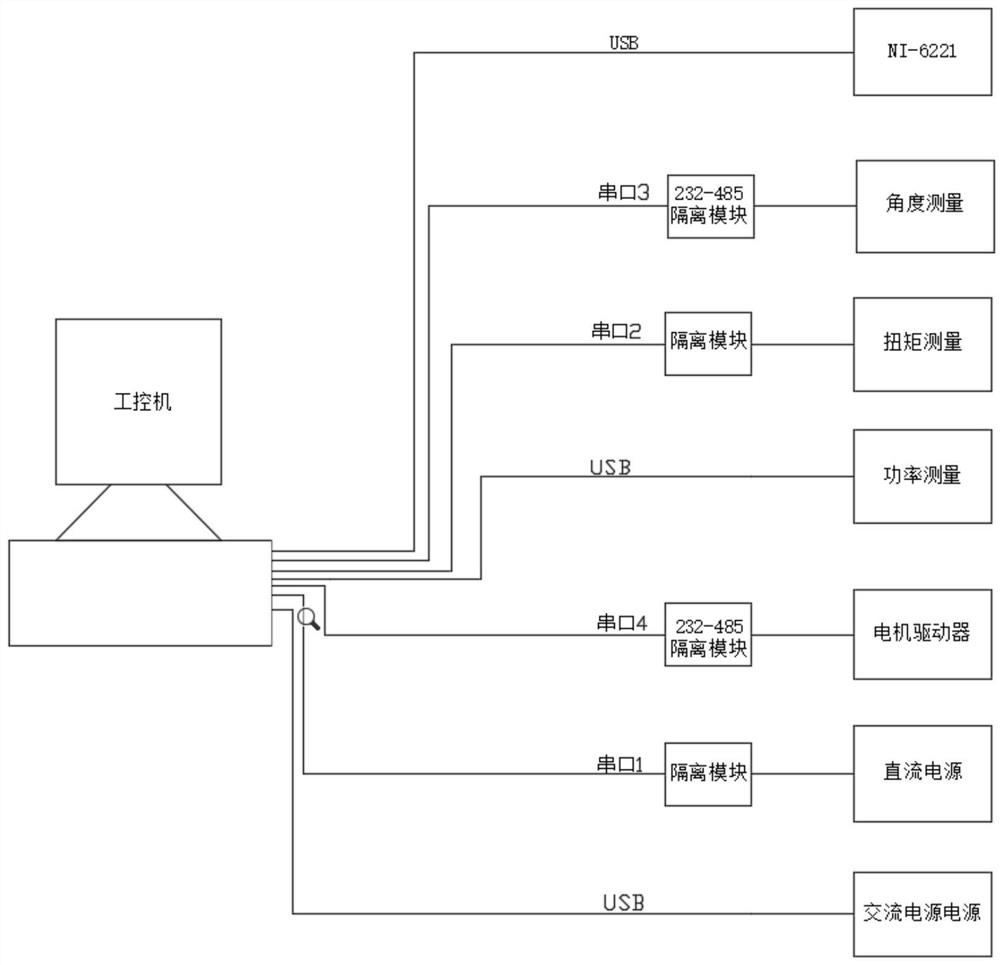

[0016] combine figure 1 As shown, the performance testing system of the rotary valve actuator includes a computer system, a control system, a data acquisition system, a fixture system and a drive system.

[0017] The computer system includes an industrial computer (industrial personal computer) and a display with a serial communication port and a USB communication port.

[0018] The control system includes a digital and analog control board connected to an industrial computer through a USB communication port, which is used to control the power supply circuit of the actuator.

[0019] The data acquisition system includes a torque sensor, an angle encoder disk, a power analyzer, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com