A kind of civil water conductive wire

A conductive wire, civilian technology, applied to the parts of the conductive core, conductors, circuits, etc., can solve problems such as potential safety hazards, energy conservation and environmental protection, and potential threats to people, and achieve the effect of ensuring safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

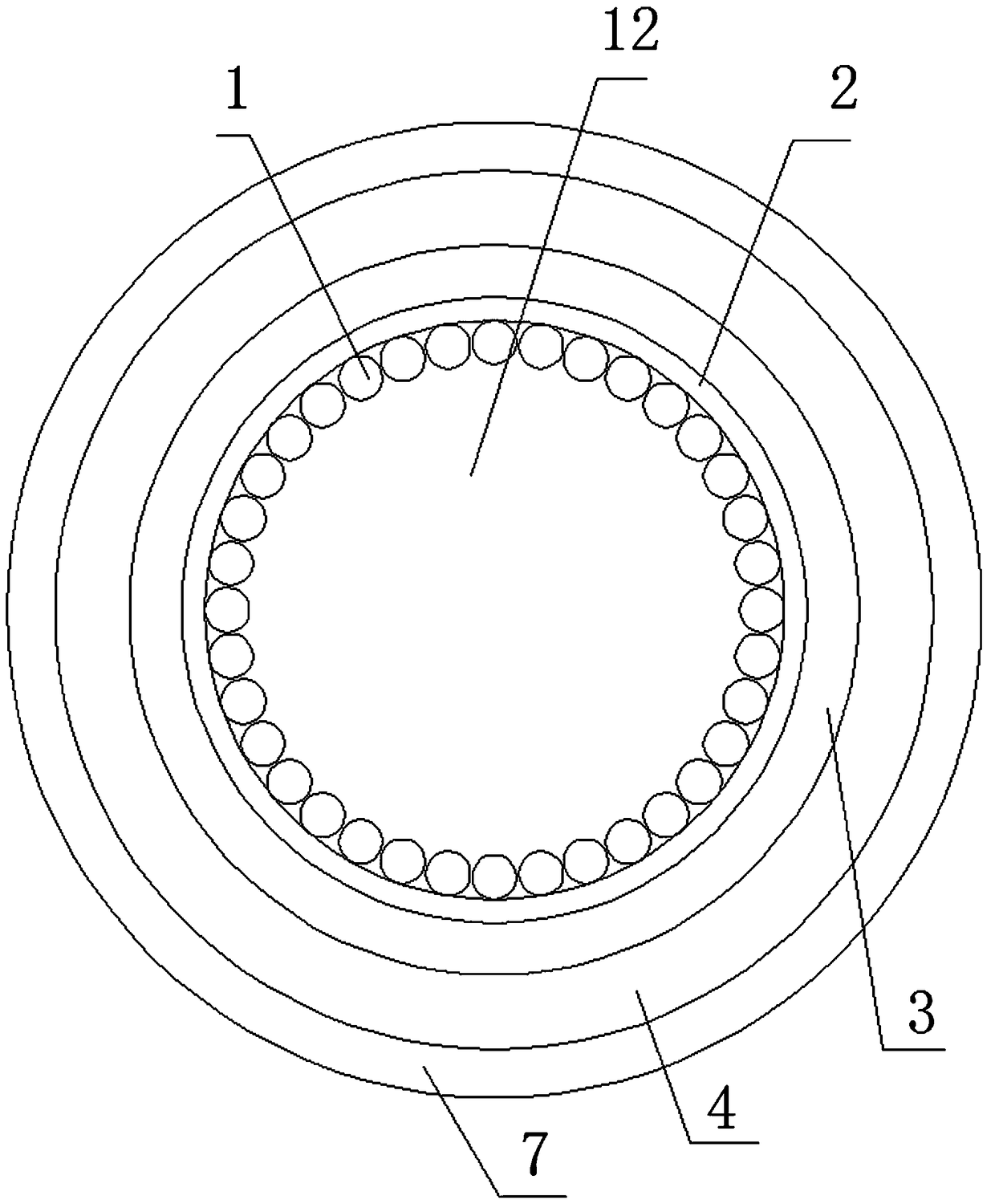

[0020] A kind of civil water conductive wire, its composition comprises: conductive core 1, described conductive core 1 is closely arranged on the inner surface of insulating layer 2, and described conductive core 1 forms circular cavity 12, and described circular cavity The body 12 is filled with a conductive solution, the outside of the insulating layer 2 is wrapped with an anti-corrosion fastening layer 3, and the outer end of the anti-corrosion fastening layer 3 is provided with a solution collection tank 4, and the solution collection tank 4 is made of stainless steel The frame 5 is connected to the anti-corrosion fastening layer 3, and a group of leakage holes 6 are arranged on the top surface of the bottom end of the solution collection tank 4, and the bottom end of the solution collection tank 4 is filled with a conductive solution neutralizing liquid, and the The outside of the solution collection tank 4 is provided with an insulating insulation layer 7.

Embodiment 2

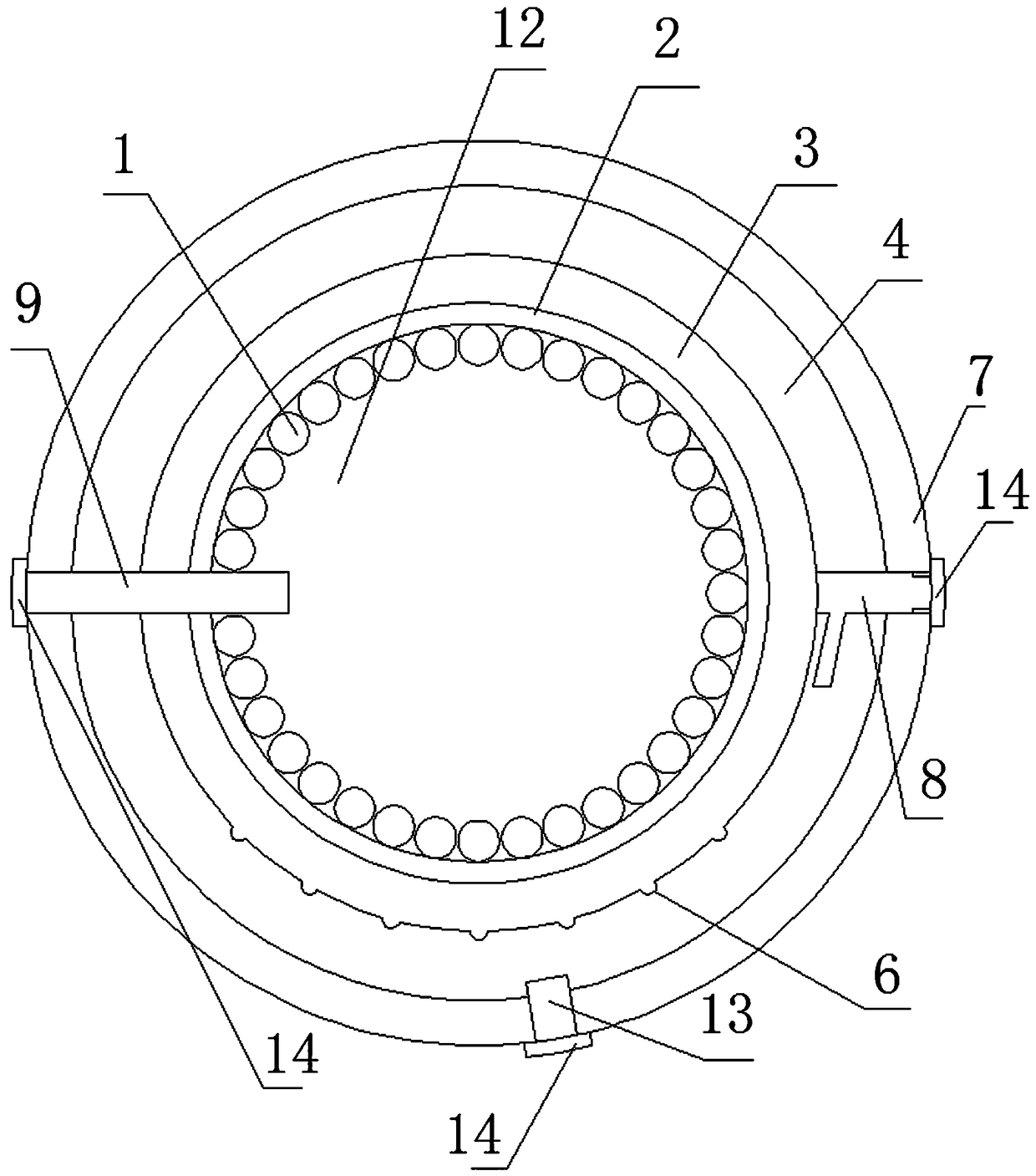

[0022] A kind of civilian water conductive wire described in embodiment 1, the top of described solution collection tank 4 is connected with T-shaped liquid inlet pipe 8, and the lower end of described solution collection tank 4 is connected with discharge pipe 13;

[0023] The circular cavity 12 communicates with the outside through the inline tube 9 .

[0024] The inline pipe 9 , the T-shaped liquid inlet pipe 8 and the liquid discharge pipe 13 are all sealed by an insulating gasket 14 .

Embodiment 3

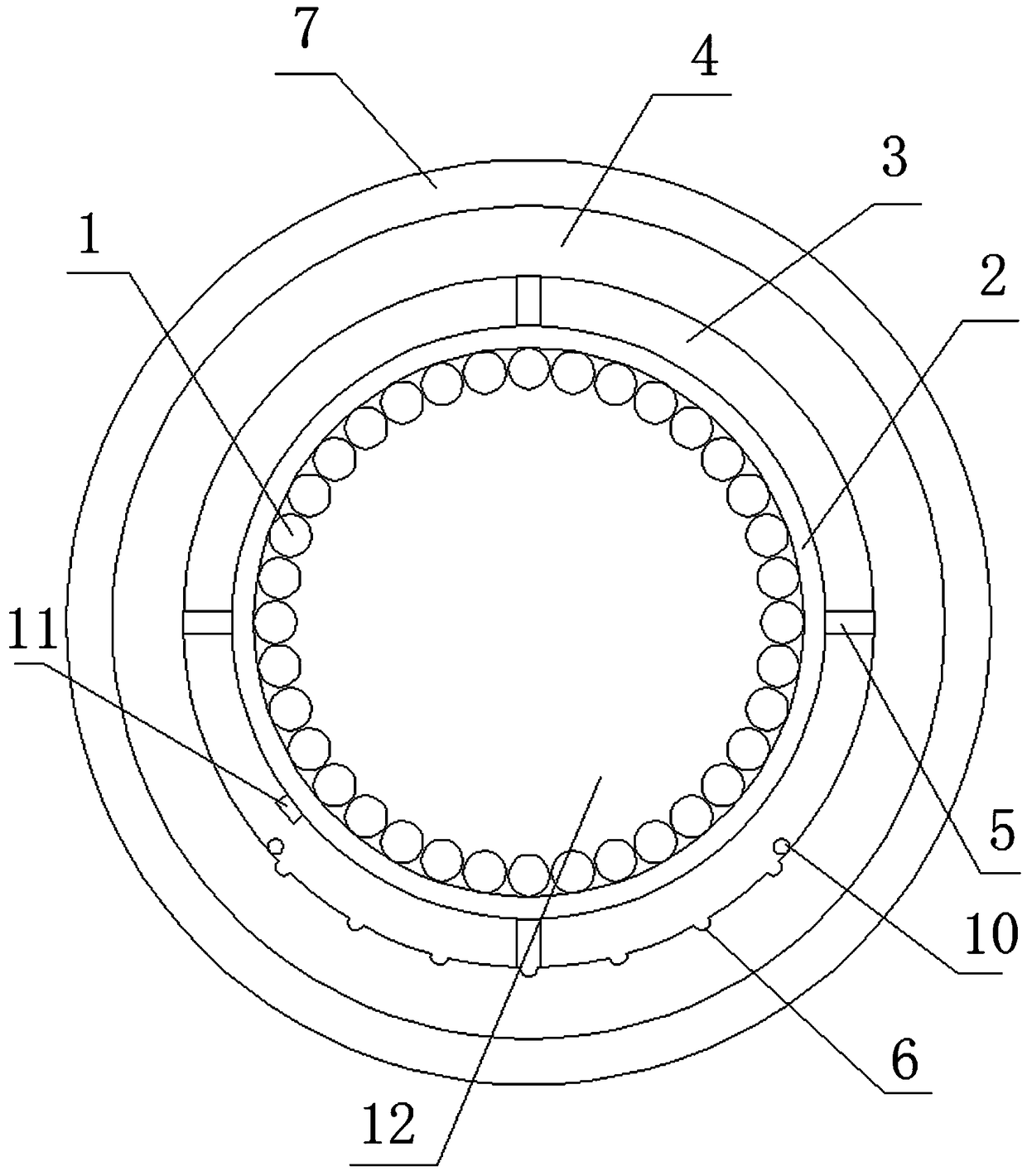

[0026] In the civil water conductive wire described in Example 1, a solution pH value sensor 10 is arranged outside the leakage hole 6, and the solution pH value sensor 10 transmits the detected analog signal to the filter amplification module, so The filter amplification module transmits the amplified analog signal to the A / D conversion module, the A / D conversion module transmits the digital signal to the single-chip microcomputer, and the single-chip microcomputer transmits the control signal to the memory and the wireless transmission module respectively, The wireless transmitting module transmits the wireless signal to the wireless receiving module, and the wireless receiving module transmits the signal to the display and the alarm respectively.

[0027] The filter amplification module, A / D conversion module, single-chip microcomputer, memory and wireless transmission module are all installed in the control box 11, and the control box 11 is arranged on the outer surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com