Equipment for forming spiral decorative patterns through cutting in sausages

A spiral and equipment technology, applied in the field of food cutting equipment, can solve the problems of high cost, unfavorable use, complex structure, etc., and achieve the effects of simple structure, avoidance of injury, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

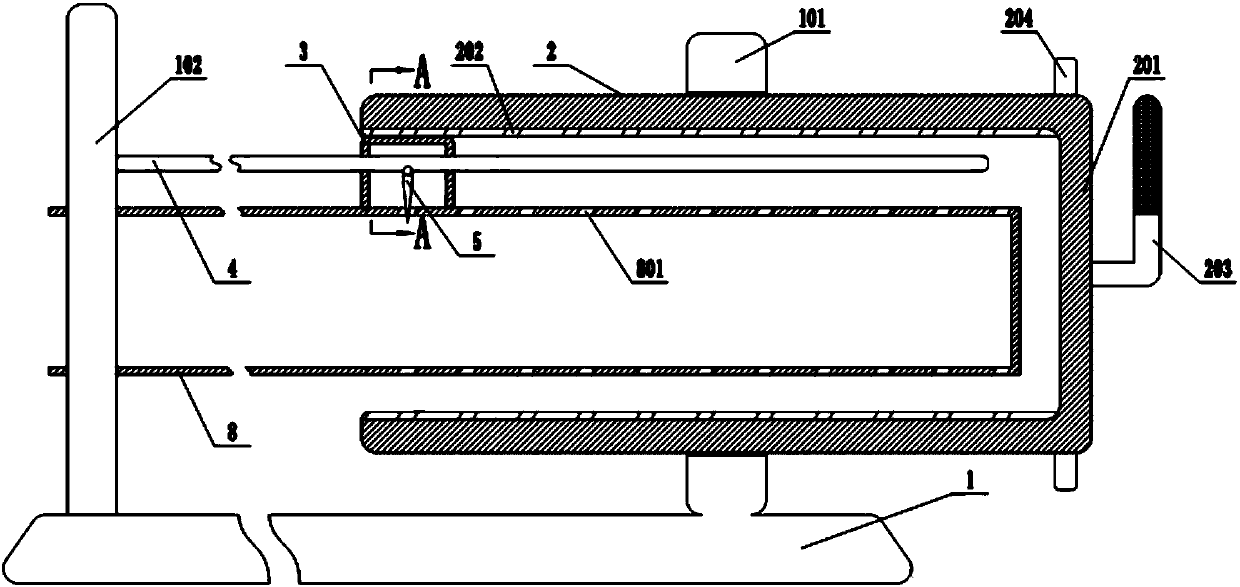

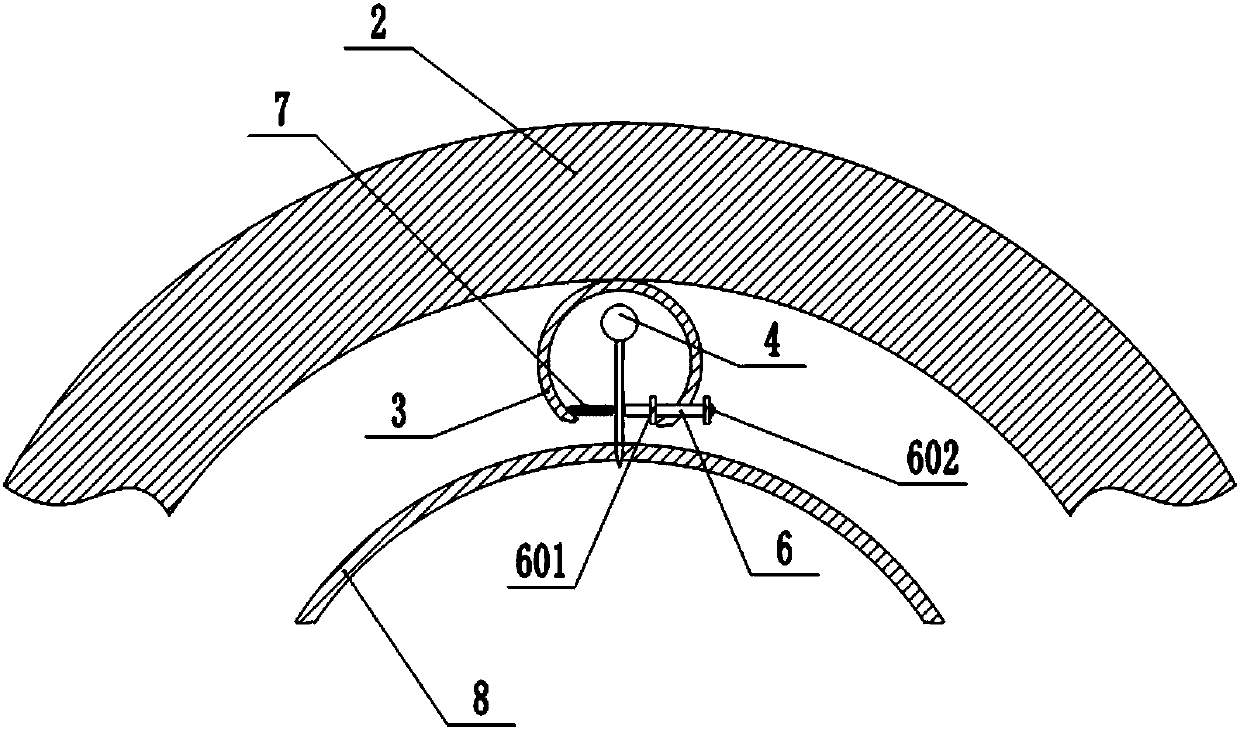

[0018] The reference signs in the accompanying drawings of the description include: fixed seat 1, support ring 101, upright column 102, rotating bucket 2, bucket cover 201, spiral internal thread 202, handle 203, retaining ring 204, slider 3, fixed slider 4 , Cutter 5, Barrier 6, First Limiting Block 601, Second Limiting Block 602, Elastic Part 7, Placement Groove 8, Spiral Cutting Groove 801.

[0019] The embodiment is basically as attached figure 1 , attached figure 2 Shown: a sausage spiral cutting equipment, including a fixed seat 1, the upper end of the fixed seat 1 is vertically provided with a support ring 101, the inner side of the support ring 101 is rotatably connected to a rotary barrel 2, and one end of the rotary barrel 2 is provided with a barrel Cover 201, the inner wall of the rotating barrel 2 is provided with a spiral internal thread 202, the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com