Multi-core-driven multistage-pressurization combined type fire-fighting and smoke-exhausting device

A smoke exhaust device and combined technology, which can be used in household heating, heating methods, space heating and ventilation details, etc., can solve the problem of increased weight and volume of hydraulic motors, insufficient exhaust air volume, no more than 4 meters, and a width of no more than 4 meters. Over 2.5 meters and other problems, to achieve the effect of increased exhaust air volume, good safety and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

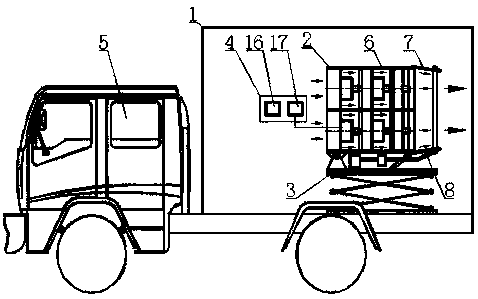

[0020] The overall structure of the combined fire-fighting and smoke-exhausting device of the present invention, such as figure 1 As mentioned above, the combined fire-fighting and smoke exhaust device 1 includes a combined smoke exhaust unit 2 , a rotary lifting mechanism 3 and a control system 4 . The combined smoke exhaust unit 2 is fixedly installed on the rotary lifting mechanism 3, and the upper part of the rotary lifting mechanism 3 is hinged with the combined smoke exhaust unit 2, so that the combined smoke exhaust unit 2 can realize the functions of rotation, pitching and lifting; the rotary lifting The bottom of the mechanism 3 is fixedly installed on a mobile or fixed carrier 5 . A control system 4 is also arranged on the carrier 5. The control system 4 can be a wireless control system or a wired control system. The present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com