A squirrel cage steel pipe connection device

A connecting device and squirrel-cage technology, which is applied in the field of steel pipe connection, can solve the problems of secondary damage to steel pipes, affect work efficiency, increase workload, etc., and achieve the effects of improving production efficiency, wide application range, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

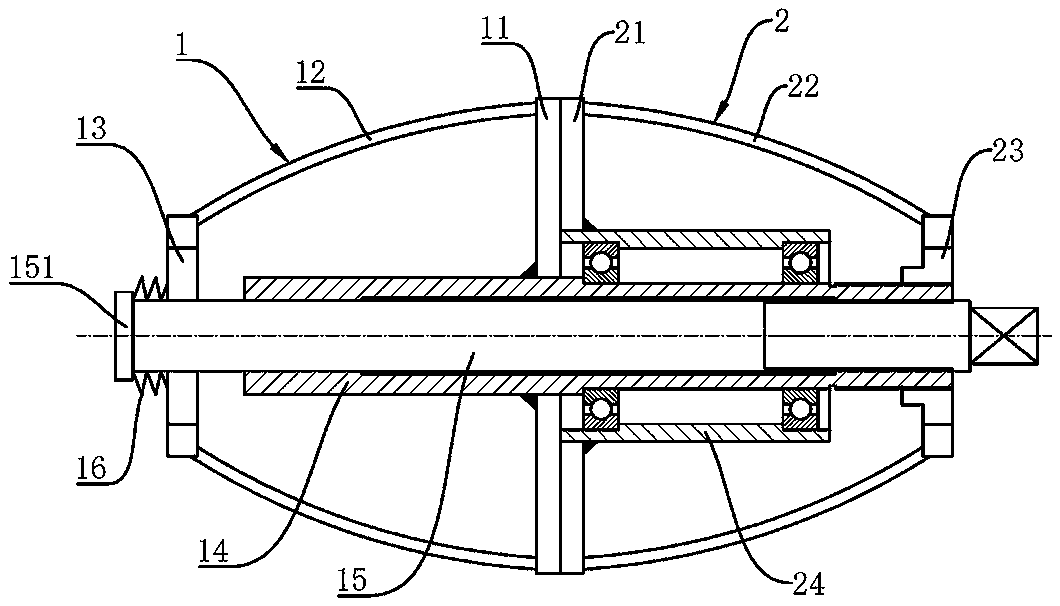

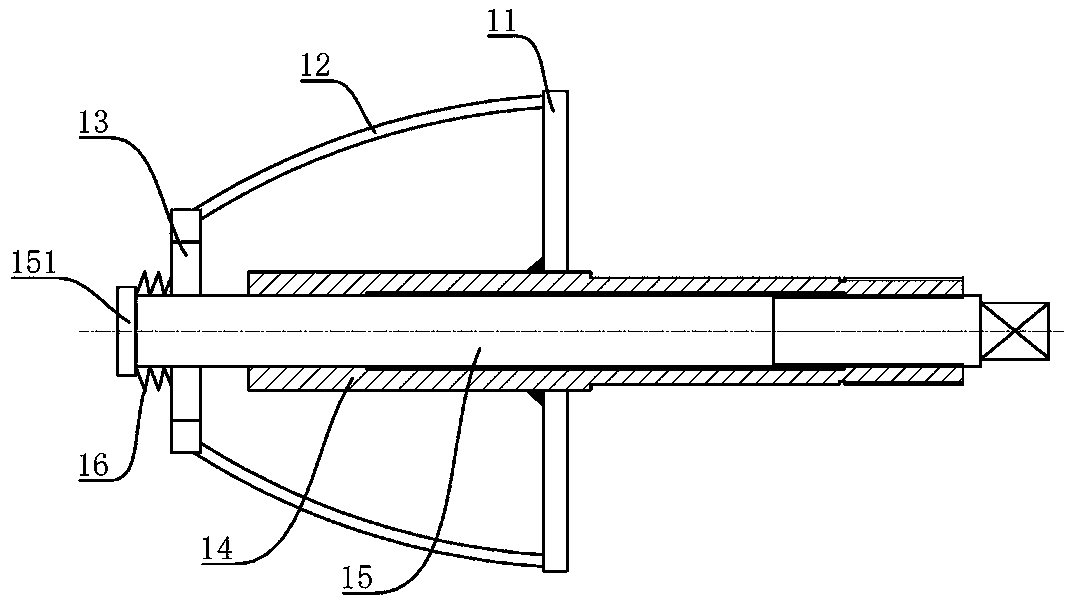

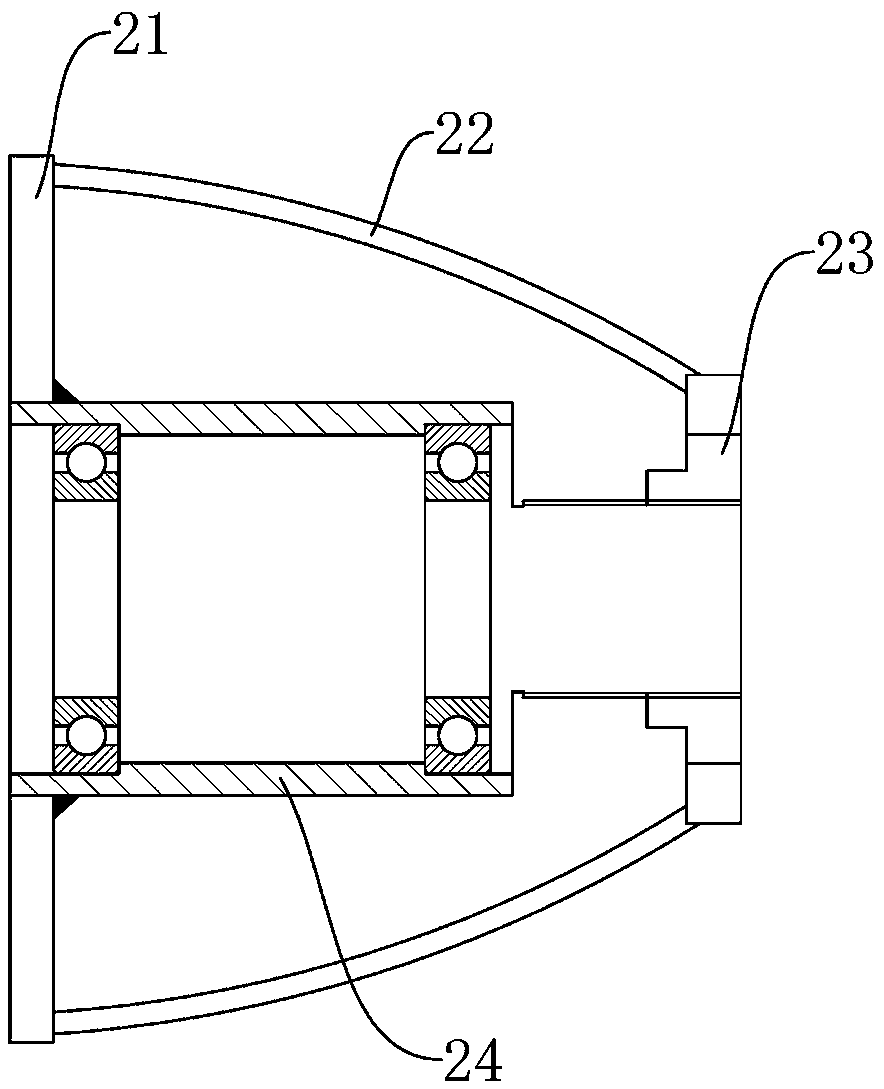

[0024] Example: such as Figure 1 to Figure 4 As shown, a squirrel-cage steel pipe connection device includes a first connection seat 1 for installation in the rear end of the previous steel pipe 3 and a second connection seat 2 for installation in the front end of the rear steel pipe 4, wherein the first The second connecting base 2 can rotate relative to the first connecting base 1 .

[0025] Such as figure 1 and figure 2 As shown, the first connecting seat 1 includes a connecting sleeve 14, a first contact bracket 12 for clamping on the inner wall of the previous steel pipe, and a first fixing frame 11 for abutting against the rear end of the previous steel pipe. The first fixing frame 11 is fixed on the connecting sleeve 14 . It also includes a first movable frame 13 and an adjusting screw 15, the first contact bracket 12 is connected between the first fixed frame 11 and the first movable frame 13, and one end thereof is welded on the first fixed frame 11, The other e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com