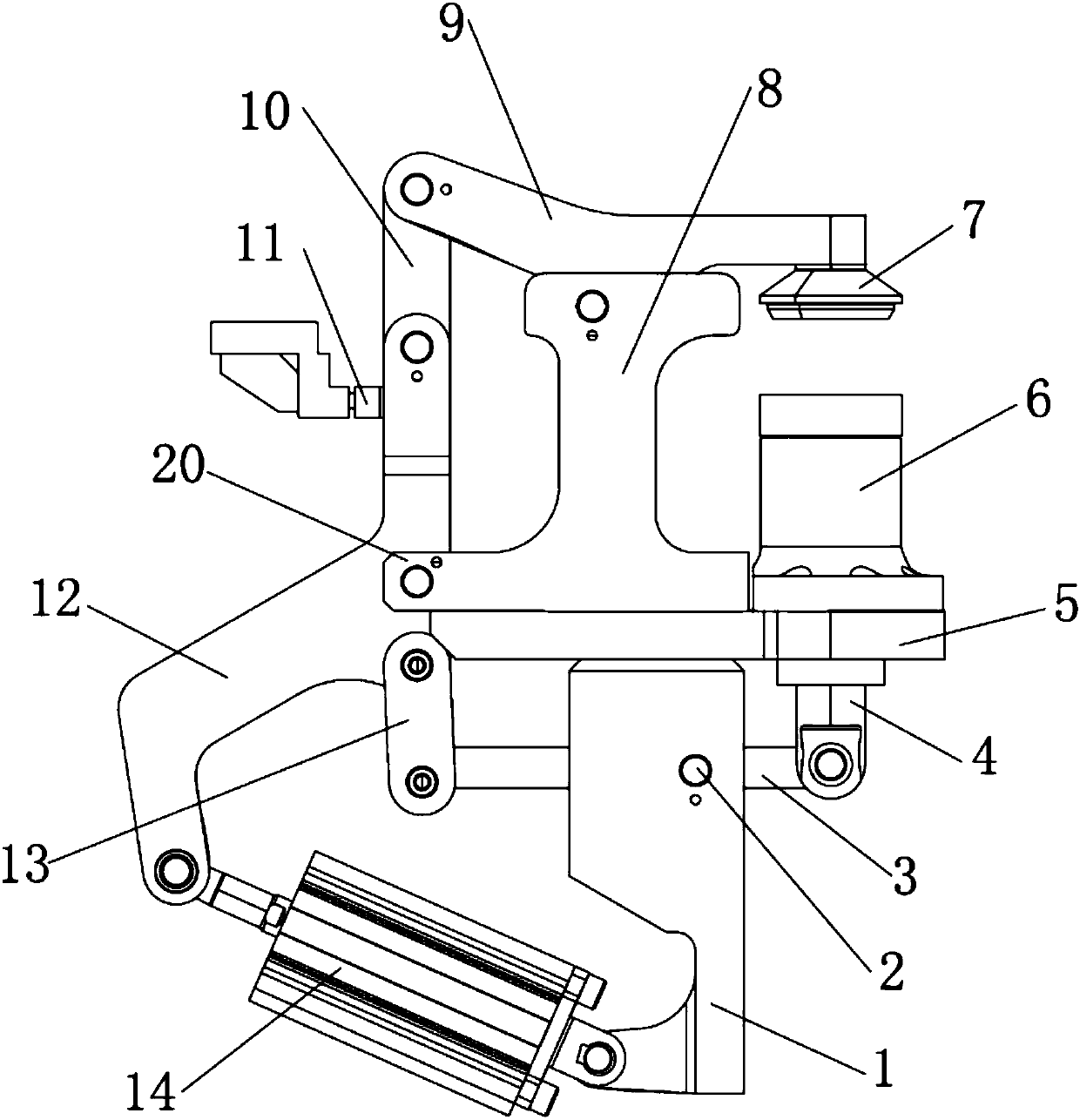

Multi-connecting-rod pressing device

A technology of pressing device and multi-linkage, which is applied to workpiece clamping devices, manufacturing tools, etc., can solve the problems of difficult positioning, complicated fixture structure, and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

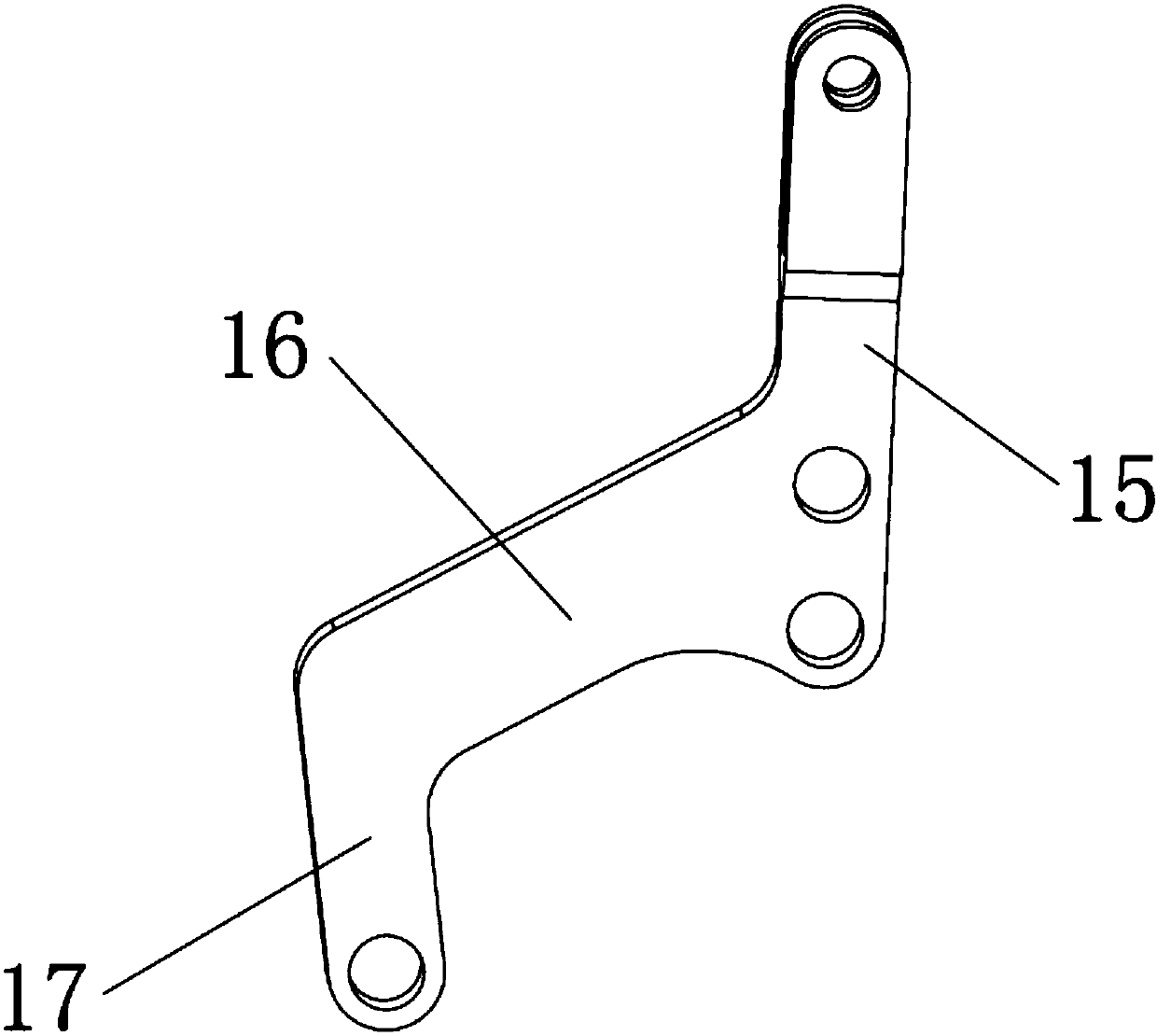

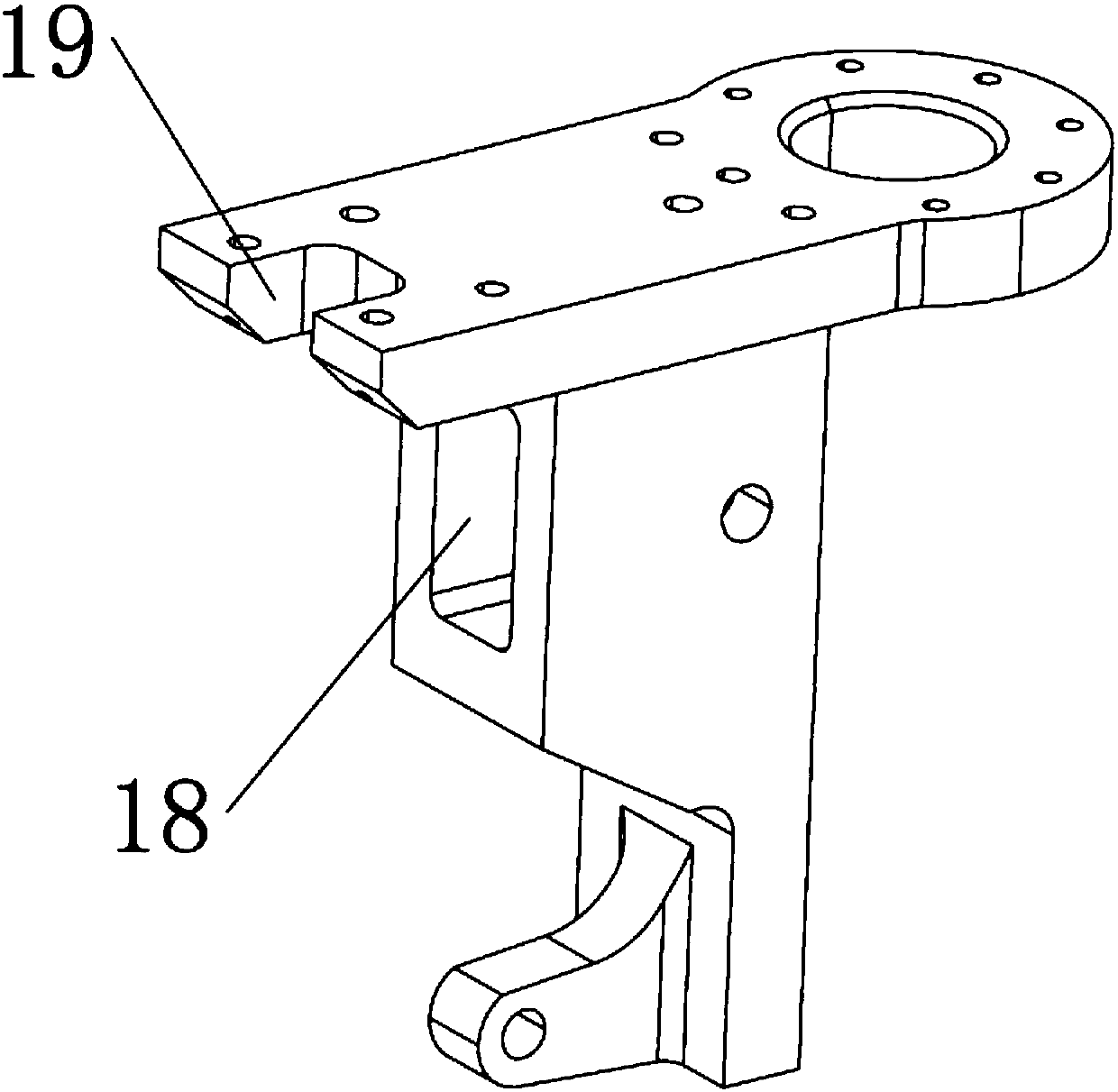

[0022] First, the piston rod of the cylinder 1 is elongated, the drive connector 12 rotates clockwise around the extension part 20, the extension part 16 drives the middle part of the vertical part 15 to rotate clockwise around the extension part 20, and the lower end of the vertical part 15 passes through the second The connecting plate 13 lifts the left end of the second connecting rod 3 upwards, and the right end of the second connecting rod 3 brings the vertical bar 4 downward synchronously, and the upper end of the vertical part 15 passes the first connecting plate 10 to the left end of the first connecting rod 9 Pull down, and the right end of the first connecting rod 9 is brought upward synchronously with the upper cover 7, and the whole pressing device is in an open state, and then the round sleeve of the product is installed in the first circular inner groove 22 of the mounting seat 6, and the solid preliminary Positioning, then control the piston rod of the cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com