Sand-filled expansion anchor rod

A technology of expanding bolts and bolts, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems of bolt influence, bolt fracture, etc., to improve the anchoring force, increase the deformation margin, and realize The effect of effective support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

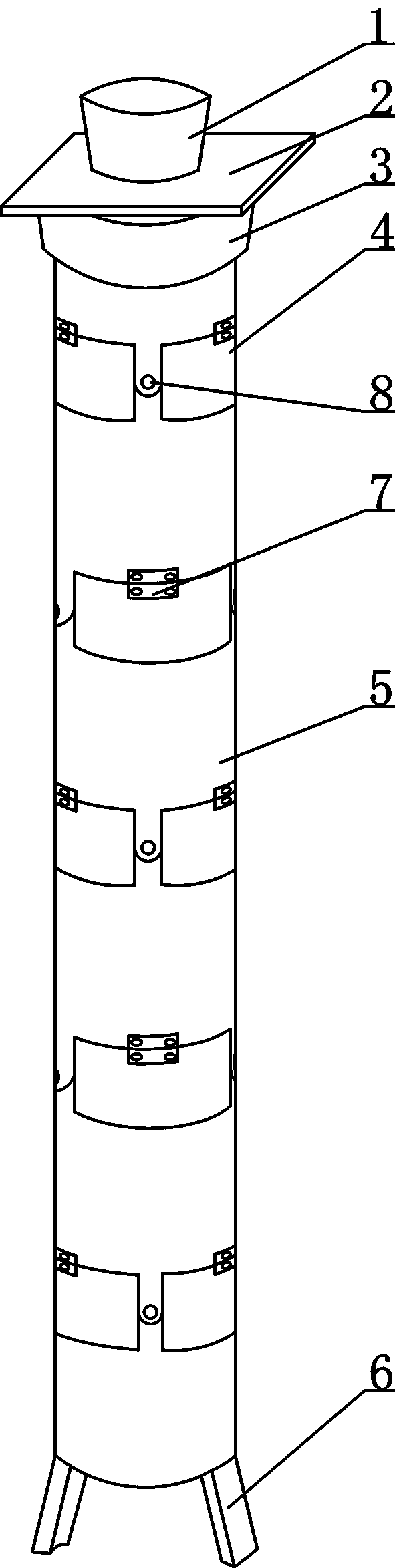

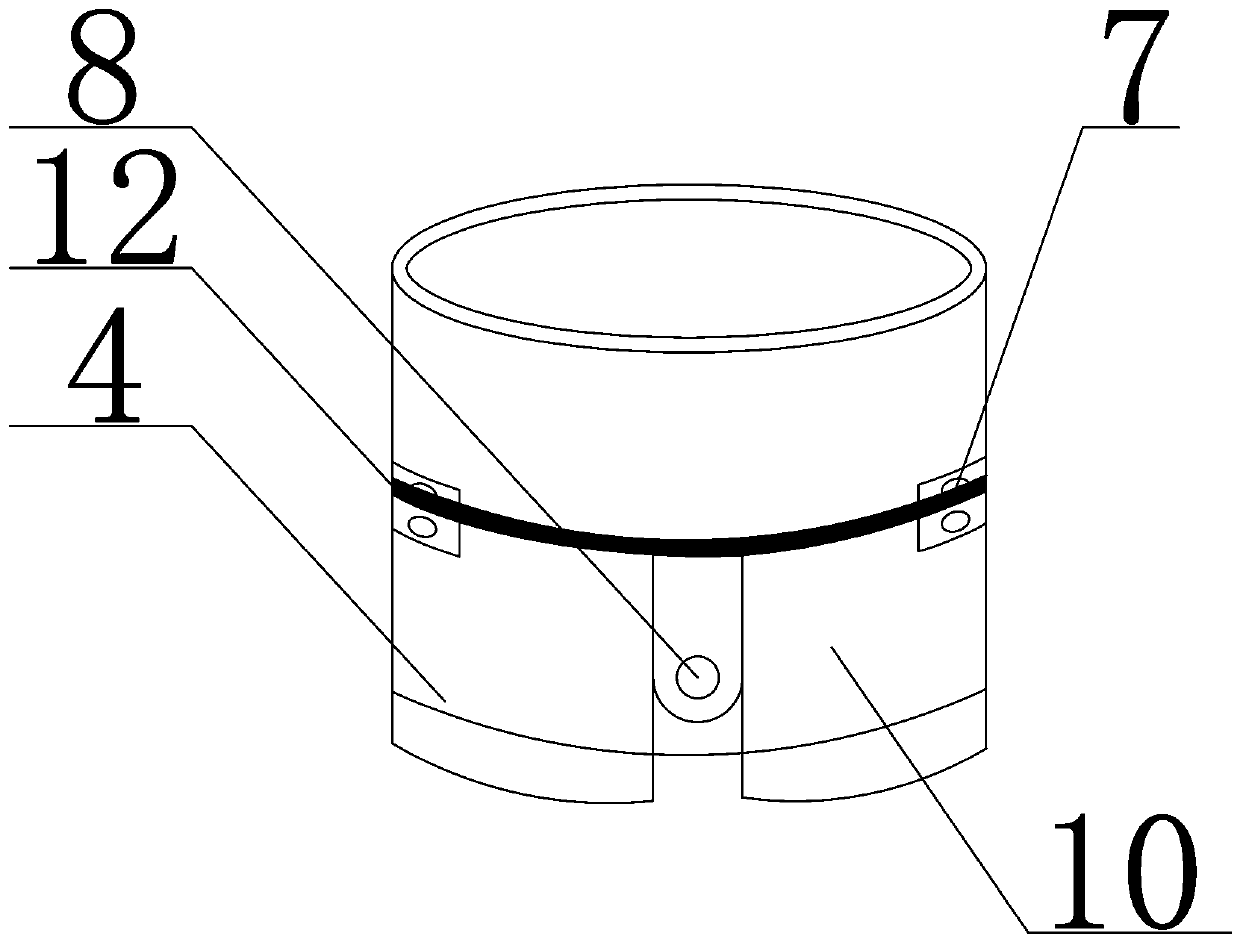

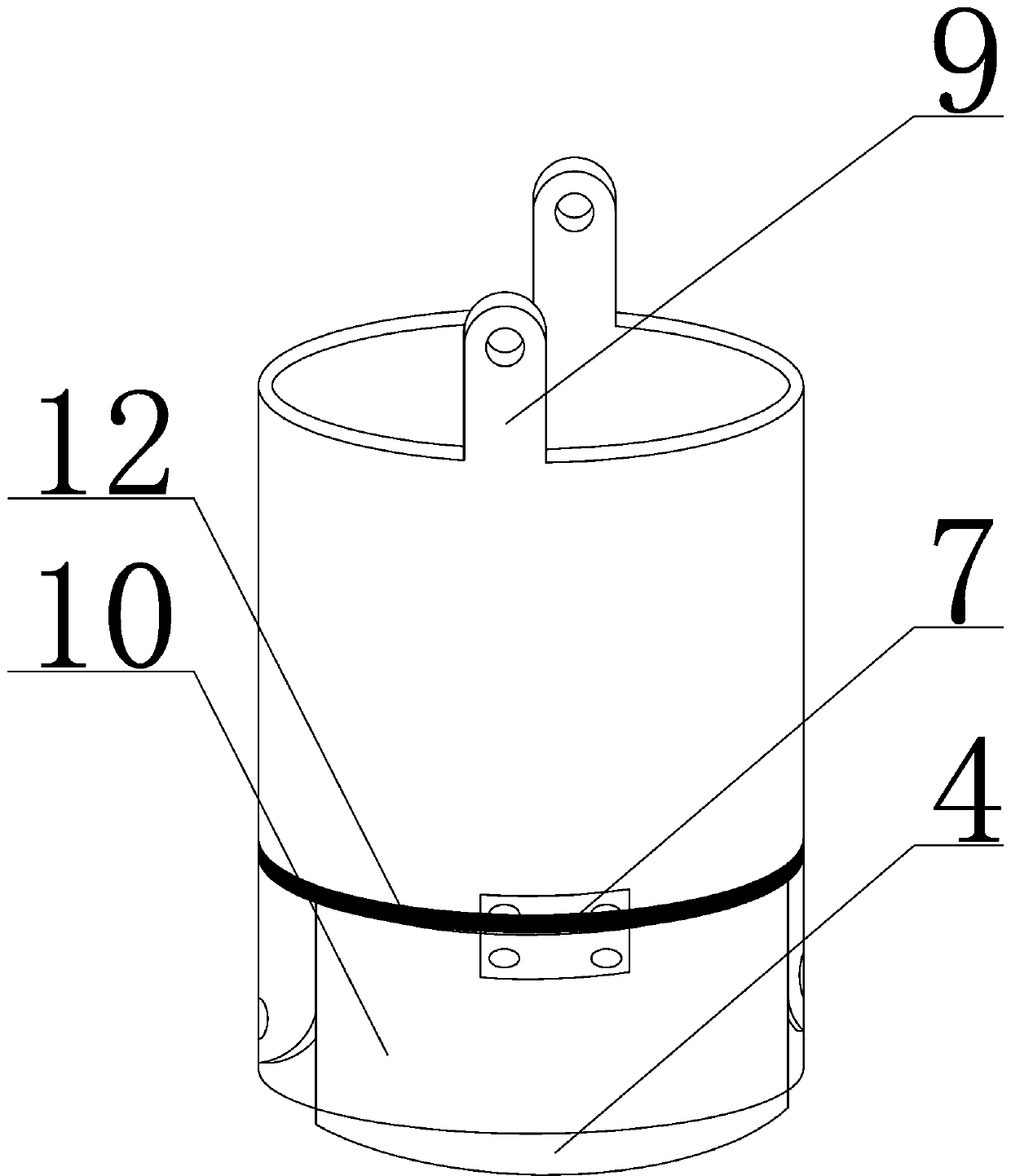

Embodiment 1

[0056] When used for temporary support:

[0057] Install the anchor head on the anchor body, and then insert the anchor body with the installed anchor head into the hole wall. The insertion angle should be consistent with the inclination angle of the drilling hole. After being inserted, the anchor body is always in the center of the drilled hole. If the hole wall collapses, the hole should be drilled and cleaned again until the anchor can be inserted smoothly. After the anchor rod is installed in the borehole, install the sand stopper and the backing plate, connect the sand injection machine through the anchor rod, start the machine to inject sand, and the sand will flow into the anchor rod body, and the expansion window surface will be pushed back, and the expansion window surface will be opened. Open the anchor hole plugging piece, the anchor hole plugging piece expands from the initial cylindrical structure to form a circular truncated shape, the expansion window surface an...

Embodiment 2

[0059] When used for permanent support:

[0060] When the pressure of the surrounding rock of the tunnel is high and the tunnel is greatly affected by excavation, the surrounding rock is a weak rock formation and a broken zone, the tunnel is located in an unstable rock mass, and the weak surface of the surrounding rock is developed, the grouting process can be used for anchoring The operation is to pour the adjusted mortar into the pump, and under the action of the pressure device, the mortar is continuously sent into the anchor body, and then the backing plate is blocked with a plug to complete the anchoring operation.

[0061] By adopting the above structure, on the basis of the existing technology, the anchor rod can be bent in a small range, and the anchor rod can be deformed accordingly for the deformation of the anchor hole caused by the movement of the rock formation during the support process, avoiding the deformation of the anchor hole In the event that an external fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com