A Coordinated Control System Calorific Value Correction Method Based on Steam Turbine Efficiency Correction

A technology for coordinating control systems and steam turbine efficiency, applied in general control systems, control/regulation systems, controllers with specific characteristics, etc., can solve problems such as parameter oscillation, unit parameter fluctuation, and heat value mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to deepen the understanding of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is exemplary and is only used to explain the present invention and not limit the scope of protection.

[0064] Introduced in conjunction with the implementation plan of a 600MW supercritical air-cooled unit, the unit uniformly adopts the international basic unit.

[0065] According to the change of steam turbine efficiency, the main control of the boiler in the coordinated control system is corrected to ensure the correctness of the output of the main control of the boiler and the accuracy of the calorific value correction circuit.

[0066] The steps of the present invention are as follows:

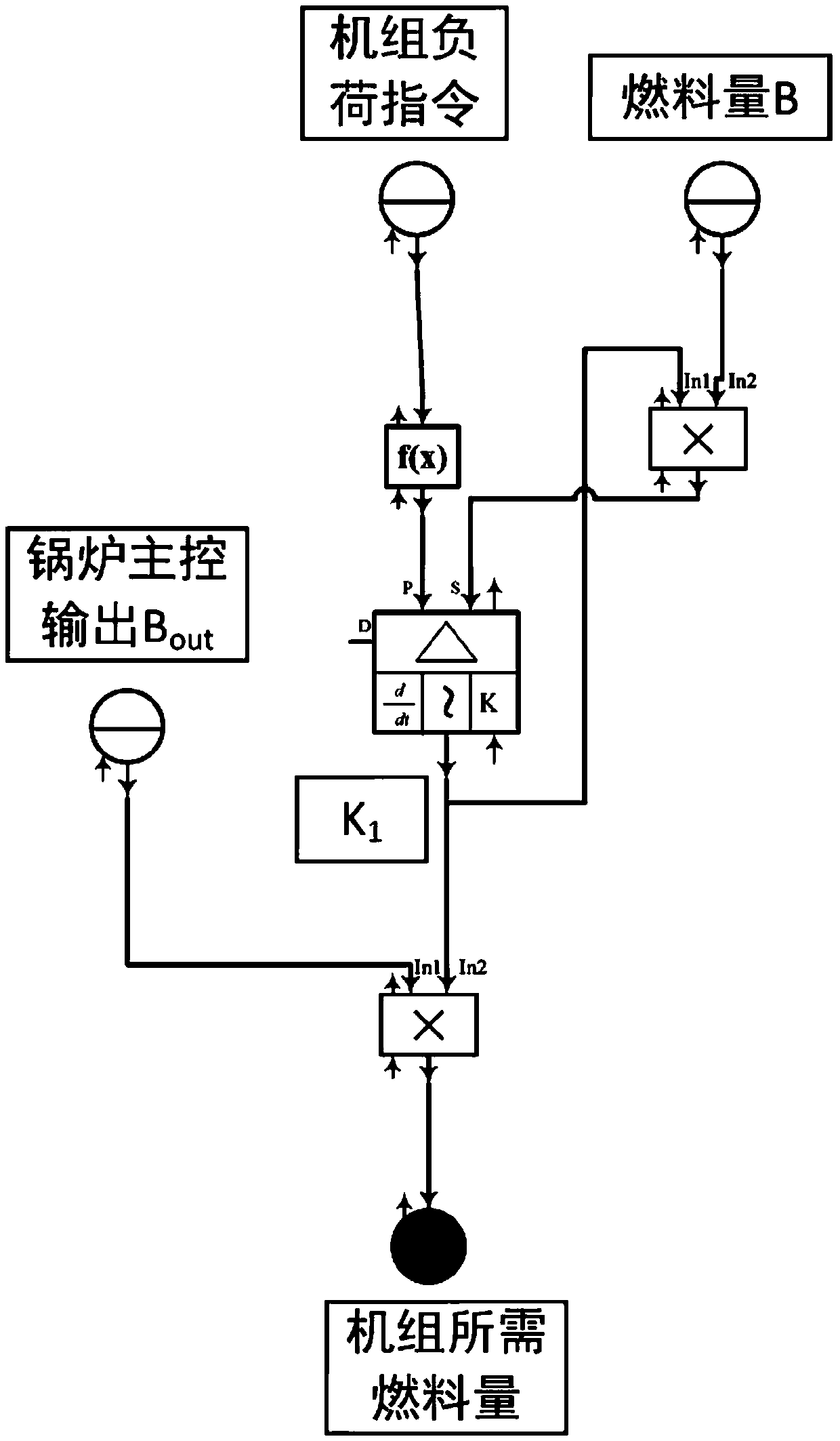

[0067] 1. Calorific value correction circuit on the boiler side

[0068] In order to decouple the steam turbine efficiency from the heating value loop, the control strategy of the boiler value correcti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com