Water-resistant tape and water-resistant zipper

A water-repellent and cloth tape technology, applied in the zipper field, can solve the problems of surface chemical agent failure, damage to the softness of the cloth tape, and troublesome operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

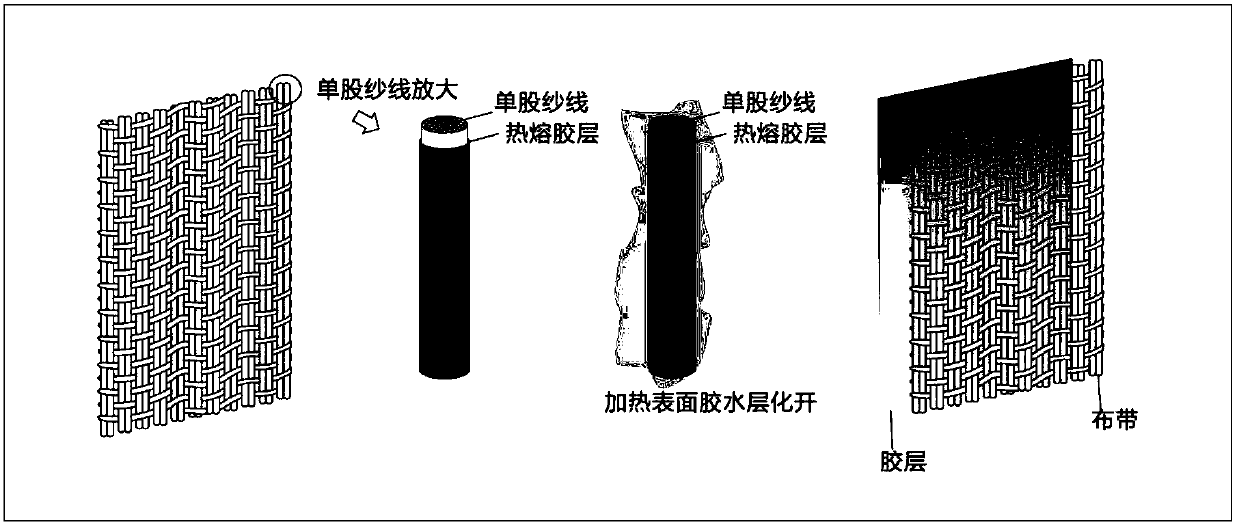

[0060] Use polyamide hot-melt adhesive with a melting point of 95°C on the market, heat it in a metal container until the hot-melt adhesive completely melts and becomes liquid, disperse and soak conventional 300D polyester filaments into the hot-melt adhesive solution, take it out, and let it dry naturally About 30 seconds, when the surface of the yarn is slightly solidified, the obtained adhesive layer yarn is coiled into rolls for use.

[0061]Use the above-mentioned adhesive layer yarns as warp and weft threads to weave zipper tapes, sew the teeth to form zipper codes; steam iron the zipper codes, the pressure of steam ironing is 0.4MPa-0.5MPa, and the surface temperature is 100 At ~130°C, the No. 7 water-repellent zipper is obtained by cutting and assembling the slider in the rear channel.

[0062] According to the above test method, test the water-repellent performance and smoothness of the water-repellent zipper. The test results are: the anti-splashing water reaches 4~...

Embodiment 2

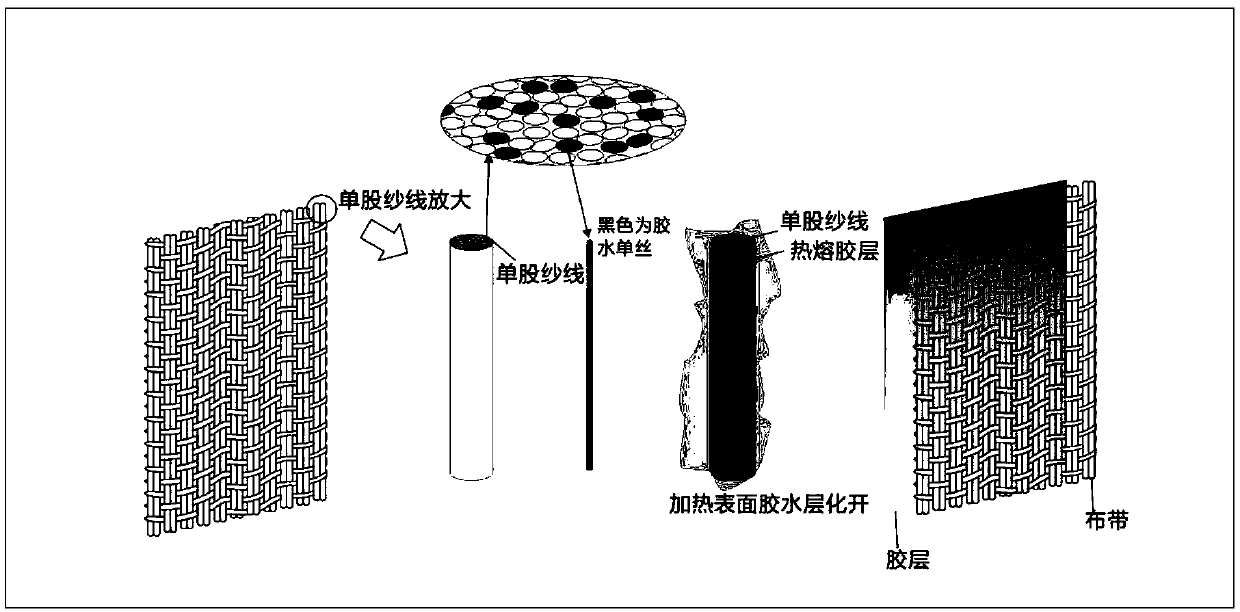

[0064] Use 150D polyester hot-melt yarn with a melting point of 95°C on the market, mix it with regular 300D polyester yarn as weft, and weave it with the warp of regular 300D polyester yarn to form a zipper tape. The hot-melt yarn is fully in contact with the warp and weft, Teeth form the zip closure. Put the zipper into a steam ironing belt, the pressure of steam ironing is 0.4MPa-0.5MPa, the surface temperature is about 100-130℃, and the slider is cut and assembled in the rear channel to make the No. 7 water-repellent zipper.

[0065] According to the above test method, test the water-repellent performance and smoothness of the water-repellent zipper. The test results are: the water repellency reaches level 4, and the smoothness is lower than 6N.

[0066] As can be seen from the above examples, the present invention provides a water-repellent cloth tape, which is obtained by the following method: weaving yarns containing hot melt adhesive, molding them with ironing tapes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Specification | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com