A kind of waterproof fabric and preparation method thereof

A waterproof fabric and waterproof finishing technology, applied in the direction of dyeing, anti-coloring and pollution/fouling fibers, liquid-repellent fibers, etc., can solve the problem that the shape and size are easy to change, the finished fabric feels hard, and cannot satisfy customers, etc. problems, to achieve good dimensional stability, soft feel, and reduce the effect of process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

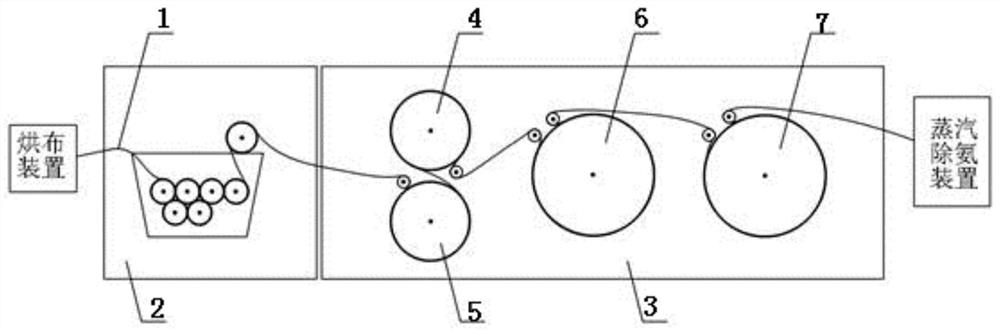

Method used

Image

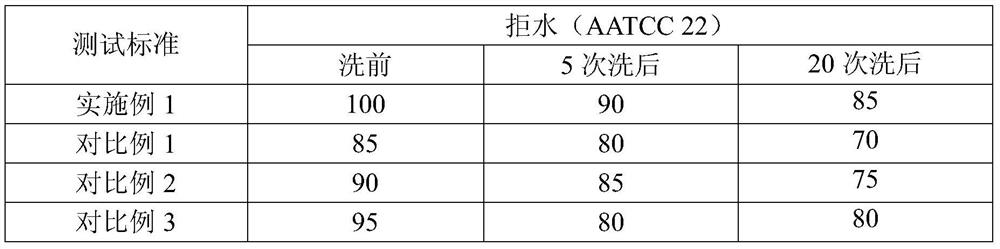

Examples

Embodiment 1

[0075] This embodiment provides a kind of waterproof knitted fabric based on cellulose fiber, the knitted fabric is 40S / 1 cotton wool cloth, and the grammage is 240g / m 2 , which is prepared by the following steps:

[0076] Scouring: 2g / L refining agent, 2g / L caustic soda, 3g / L H 2 o 2 solution. The scouring temperature is 95°C, and the processing time is 50 minutes.

[0077] Enzyme washing: Arrange the knits after scouring in the enzyme treatment solution. The enzyme treatment solution is: 2g / L ZJ-X04 (Guangzhou Zhuangjie Chemical Co., Ltd.), 0.50g / L acetic acid and 0.5g / L of sodium acetate. The treatment time is 50min, the treatment temperature is 60°C, the pH is 5.5, and the liquor ratio is 1:10. Then perform enzyme inactivation: hot water treatment at 80°C for 10 minutes.

[0078] Dyeing: Disperse Black: 1.2%, Disperse Crimson: 2.04%, Disperse Yellow Brown: 1.3%, Reactive Black: 1.2% owf, Reactive Yellow: 0.4% owf, Reactive Red: 1.34% owf, bath ratio 1:5, yuan The d...

Embodiment 2

[0092] This embodiment provides a waterproof knitted fabric mainly composed of cellulose fibers. The knitted fabric is 44S / 1+75D / 72F[S] / 1 cotton-polyester blended double-sided jacquard fabric, with a weight of 225g / m 2 , which is prepared by the following steps:

[0093] Scouring: 2g / L refining agent, 2g / L caustic soda, 3g / L H 2 o 2 solution. The temperature of scouring is 95 ℃, and the time of scouring is 50min.

[0094]Enzyme washing: Arrange the scoured knitting in the enzyme treatment solution. The enzyme treatment solution is: 2g / L ZJ-X04 (Guangzhou Zhuangjie Chemical Co., Ltd.), 0.50g / L acetic acid and 0.5 g / L of sodium acetate. The treatment time is 50min, the temperature is 60°C, the pH is 5.5, and the bath ratio is 1:10. Then perform enzyme inactivation: hot water treatment at 80°C for 10 minutes.

[0095] Dyeing: disperse black: 0.2%, disperse deep red: 0.04%, disperse yellow brown: 0.13%, reactive black: 3.0% owf, reactive yellow: 0.2% owf, reactive red: 0.5%...

Embodiment 3

[0109] This embodiment provides a waterproof knitted fabric mainly composed of cellulose fibers. The knitted fabric is 50D / 36F[S] / 1+16S / 1+20S / 1 cotton-polyester blended sweater fabric with a weight of 360g / m 2 , which is prepared by the following steps:

[0110] Scouring: 2g / L refining agent, 2g / L caustic soda, 3g / L H 2 o 2 solution. The temperature of scouring is 95 ℃, and the time of scouring is 50min.

[0111] Enzyme washing: Arrange the knits after scouring in the enzyme treatment solution. The enzyme treatment solution is: 2g / L ZJ-X04 (Guangzhou Zhuangjie Chemical Co., Ltd.), 0.50g / L acetic acid and 0.5g / L of sodium acetate. The treatment time is 50min, the temperature is 60°C, the pH is 5.5, and the bath ratio is 1:10. Then perform enzyme inactivation: hot water treatment at 80°C for 10 minutes.

[0112] Dyeing: disperse black: 0.12%, disperse deep red: 0.04%, disperse yellow brown: 0.18%, reactive black: 0.1% owf, reactive yellow: 1.56% owf, reactive red: 2.0% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com