Water-repellent TPU (thermoplastic polyurethane) hot melt adhesive film and preparation method thereof

A hot-melt adhesive and water-repellent technology, which is applied in the field of composite materials, can solve the problems of low melting point of films, restrictions on wide-scale application and promotion, poor low-temperature performance, etc., and achieve improved mechanical properties, excellent water-repellent properties and mechanical properties , Excellent water-repellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

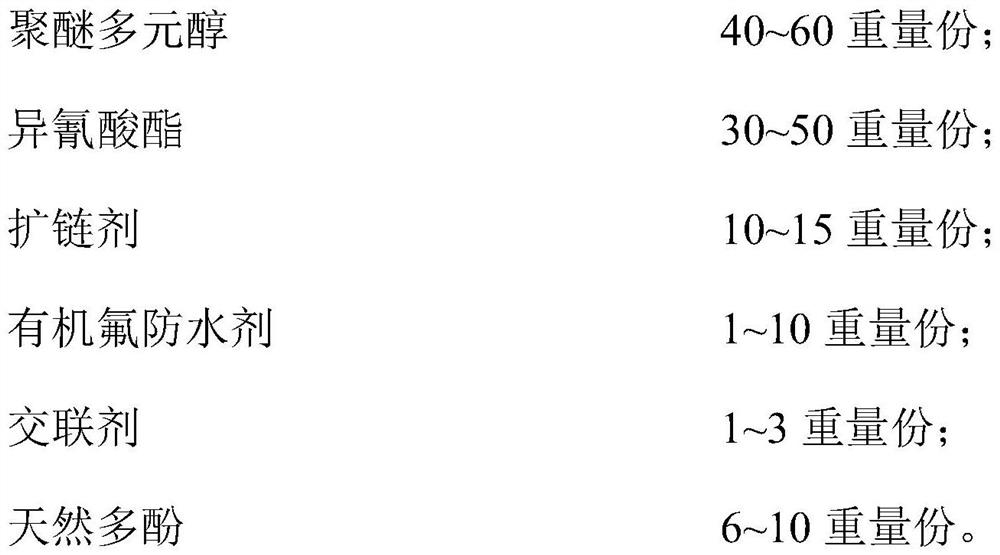

[0058] A kind of water-repellent TPU hot-melt adhesive film, its preparation raw material comprises following component according to weight part:

[0059]

[0060] The preparation method of the water-repellent TPU hot-melt adhesive film provided by the present embodiment comprises the following steps:

[0061] (1) react polytetramethylene ether glycol, polyethylene glycol (molecular weight: 3000Da) and hexamethylene diisocyanate at 75°C for 2.5h to obtain a polyurethane prepolymer;

[0062] (2) react the polyurethane prepolymer obtained in step (1), 1,4-butanediol, vinyl bis stearamide and catalyst (CT-E229) at 50°C for 10 hours, and extrude to obtain TPU particles;

[0063] (3) Pass the TPU particles obtained in step (2), C6 fluorocarbon compound, tea polyphenol, di-tert-butyl p-cresol, isopropanol and modified cellulose ether thickener (PRIME1000) at 180°C The single-screw extruder at 50 rpm melts and extrudes, cools and stretches to obtain the water-repellent TPU hot-me...

Embodiment 2

[0065] A kind of water-repellent TPU hot-melt adhesive film, its preparation raw material comprises following component according to weight part:

[0066]

[0067]

[0068] The preparation method of the water-repellent TPU hot-melt adhesive film provided by the present embodiment comprises the following steps:

[0069] (1) reacting polytetramethylene ether glycol, polyethylene glycol (molecular weight: 2000Da) and isophorone diisocyanate at 70°C for 3 hours to obtain a polyurethane prepolymer;

[0070] (2) react the polyurethane prepolymer obtained in step (1), 1,4-butanediol, vinyl bis stearamide and catalyst (CT-E229) at 40°C for 12 hours, and extrude to obtain TPU particles;

[0071] (3) The TPU particles obtained in step (2), C8 type fluorocarbons, tea polyphenols, di-tert-butyl p-cresol, isopropanol and modified cellulose ether thickener (PRIME1000) are passed through the rotating speed at 170°C The single-screw extruder of 100 rpm melts and extrudes, cools and str...

Embodiment 3

[0073] A kind of water-repellent TPU hot-melt adhesive film, its preparation raw material comprises following component according to weight part:

[0074]

[0075]

[0076] The preparation method of the water-repellent TPU hot-melt adhesive film provided by the present embodiment comprises the following steps:

[0077] (1) reacting polytetramethylene ether glycol, polyethylene glycol (molecular weight: 5000Da) and isophorone diisocyanate at 80°C for 2 hours to obtain a polyurethane prepolymer;

[0078] (2) React the polyurethane prepolymer obtained in step (1), 1,4-butanediol, vinyl bis stearamide and catalyst (CT-E229) at 60°C for 6 hours, and extrude to obtain TPU particles;

[0079] (3) The TPU particles obtained in step (2), C8 type fluorocarbons, tea polyphenols, di-tert-butyl p-cresol, isopropanol and modified cellulose ether thickener (PRIME1000) are passed through the rotating speed at 200°C The single-screw extruder of 30 rpm melts and extrudes, cools and stret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com