A friction-assisted heat flat bottom riveting-free connection method for lightweight plates

A riveting and lightweight technology, which is applied in the field of friction-assisted heating flat-bottom riveted connection, can solve the problems of poor reliability of riveted joints, large riveting forming force, deformation and cracking, etc., achieve low mold cost, reduce riveting force, and reduce brittleness. cracking tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] A friction-assisted heating flat-bottom rivetless connection method for lightweight plates, comprising the following steps:

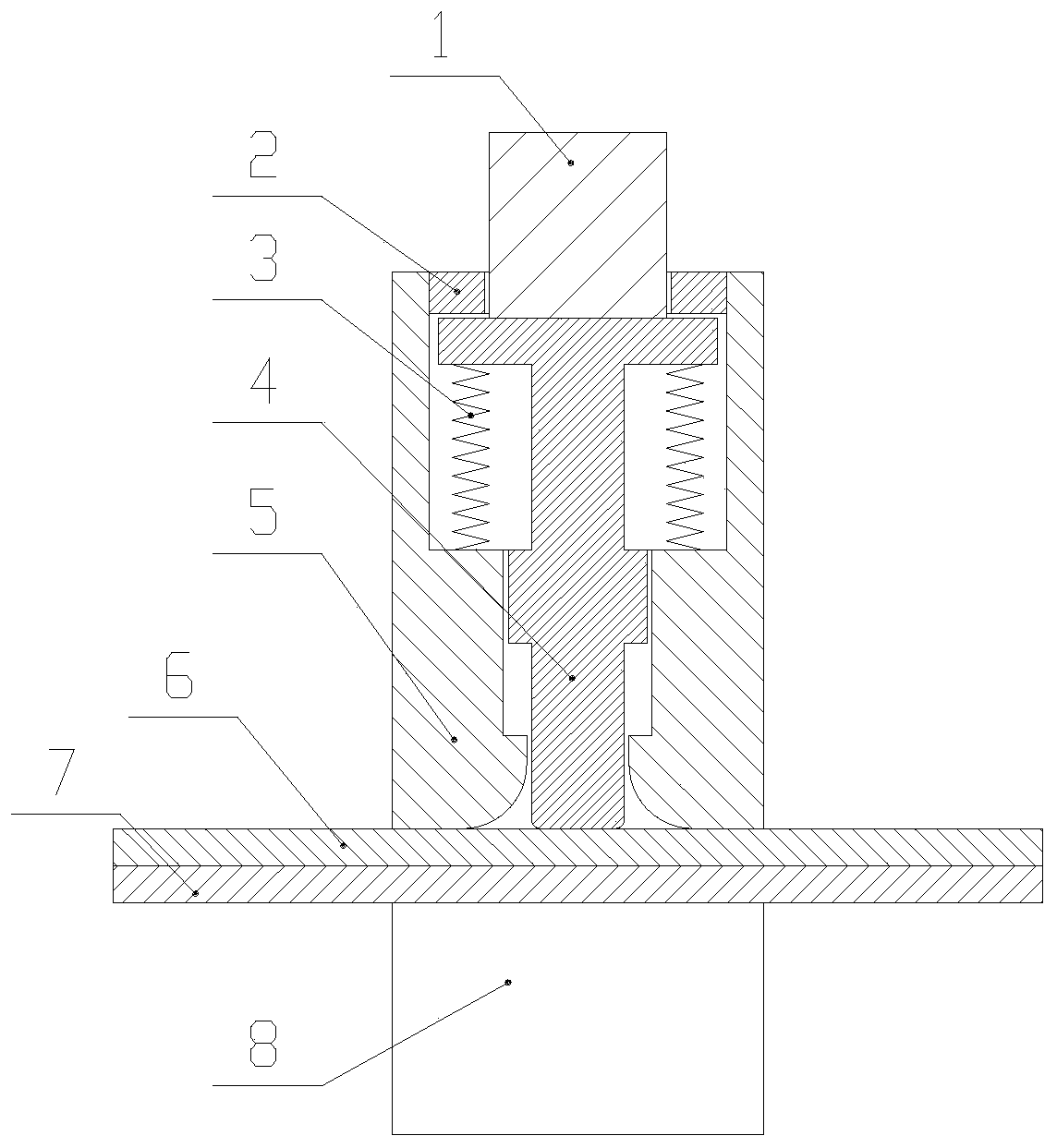

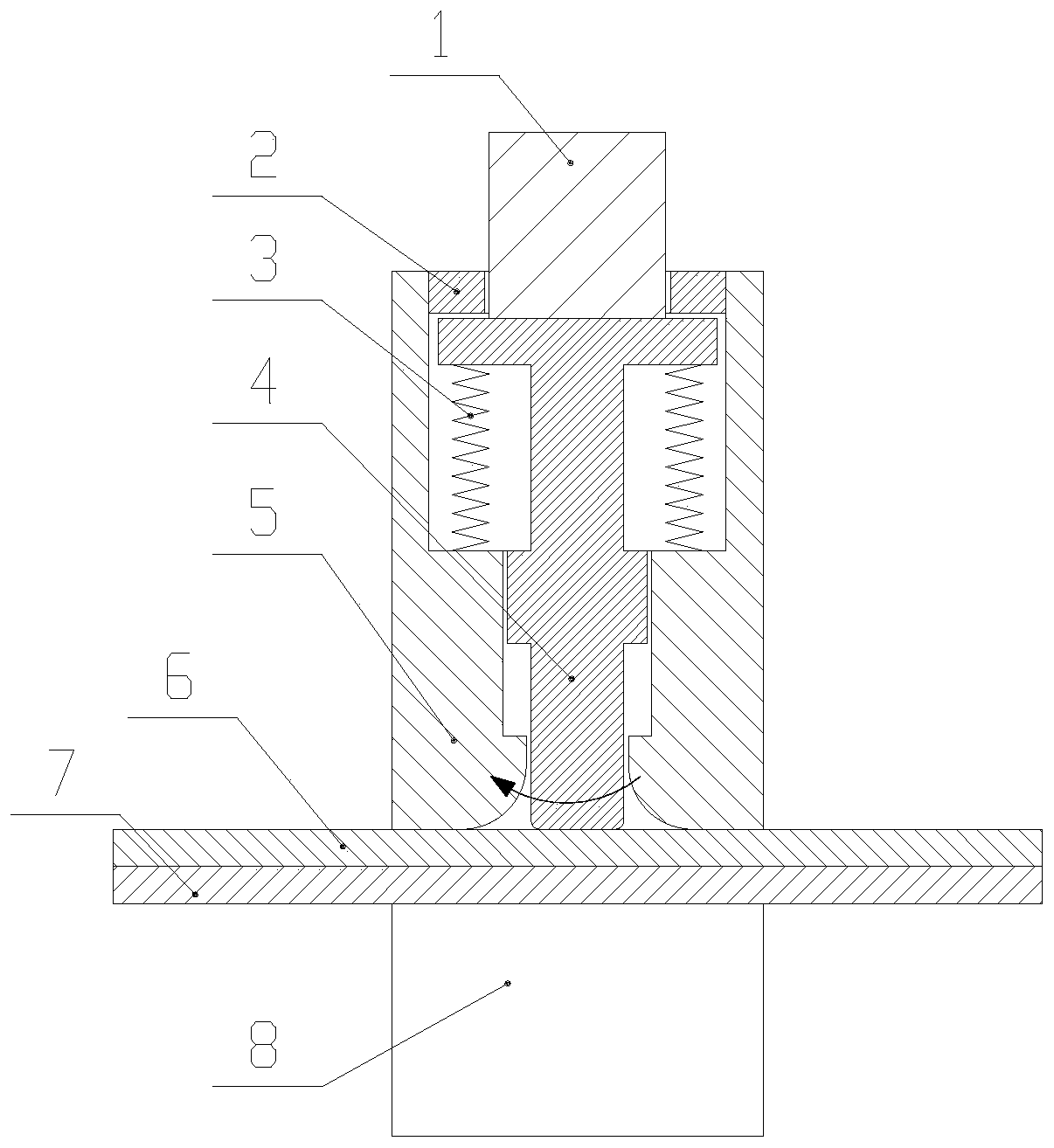

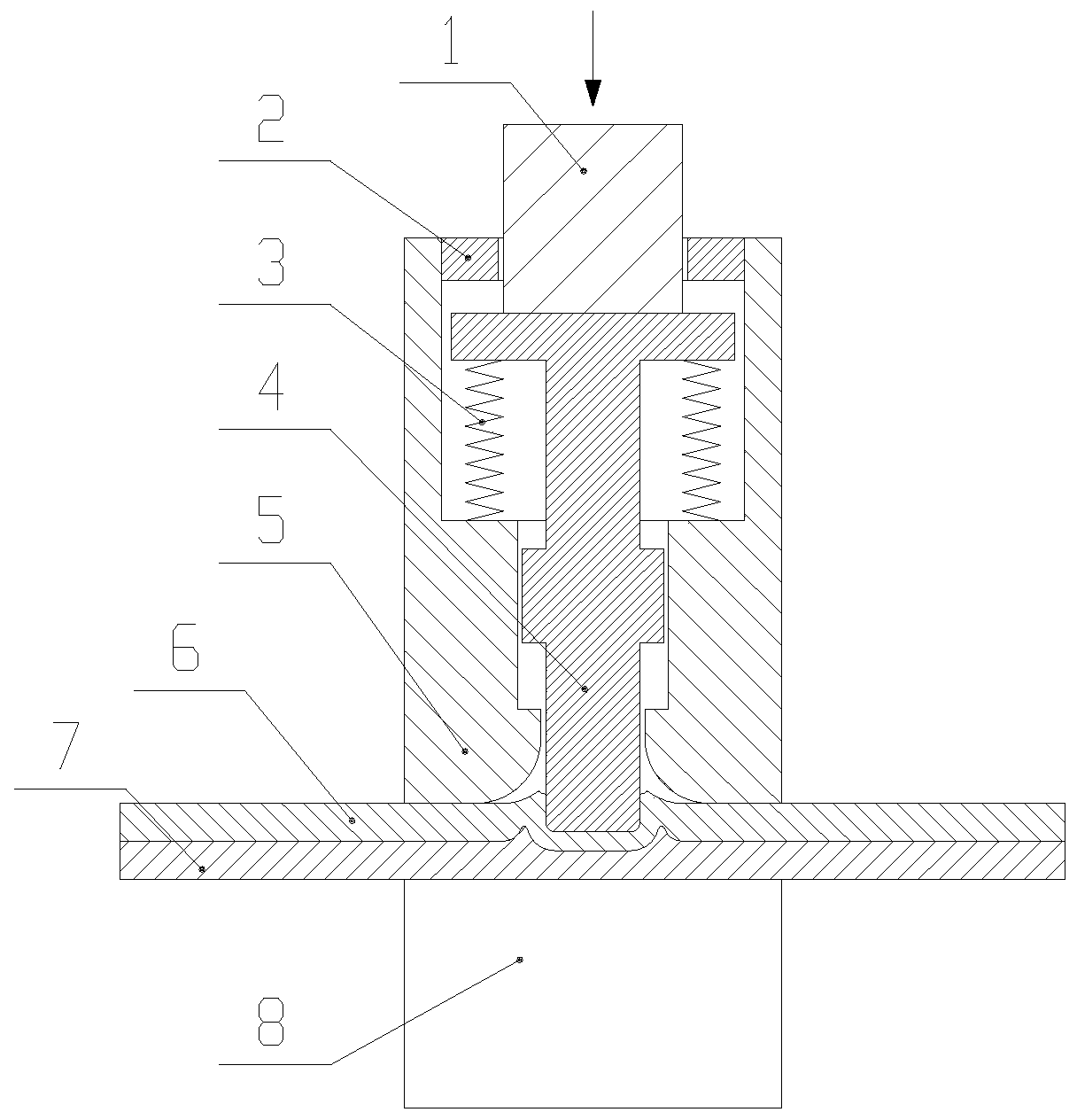

[0025] 1) Positioning stage: refer to figure 1 , before the connection starts, the upper plate 6 and the lower plate 7 are clamped and fixed and stacked on the lower mold 8, and the lower mold 8 is fixed; the friction head 5 and the punch 4 move downward as a whole, and the friction head 5 and the punch 4 The upper plate 6 and the lower plate 7 are partially positioned on the lower mold 8, and pressure is applied; the up and down movement of the punch 4 is realized by the joint action of the stamping power source, the pressure head 1 and the ring spring 3, and the punch 4 and the ring spring 3 The retaining ring 2 is installed inside the friction head 5, and the key groove inside the friction head 5 cooperates with the key in the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com