Paper cup groove forming device of paper cup machine

A technology of a forming device and a paper cup machine, which is applied to cardboard articles and other directions, can solve the problems of complex structure and high production cost, and achieve the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

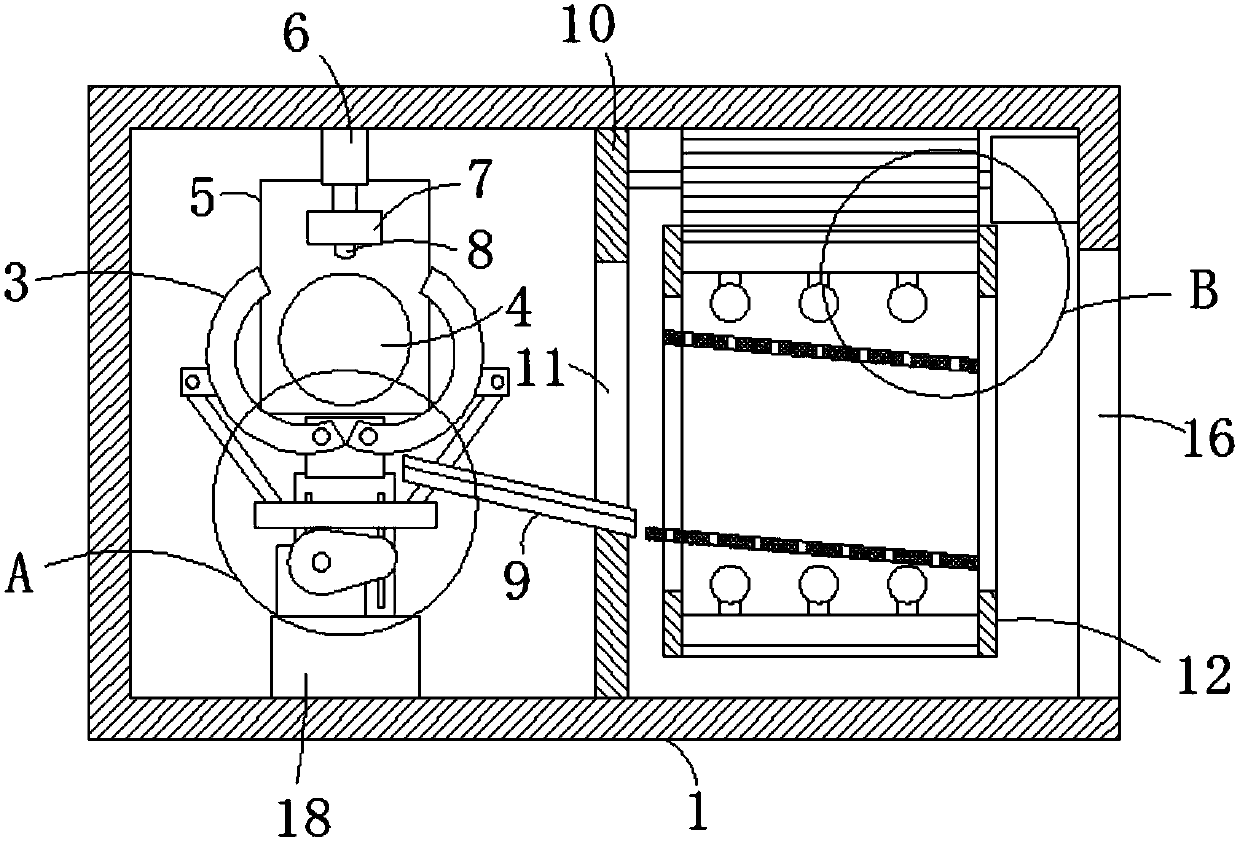

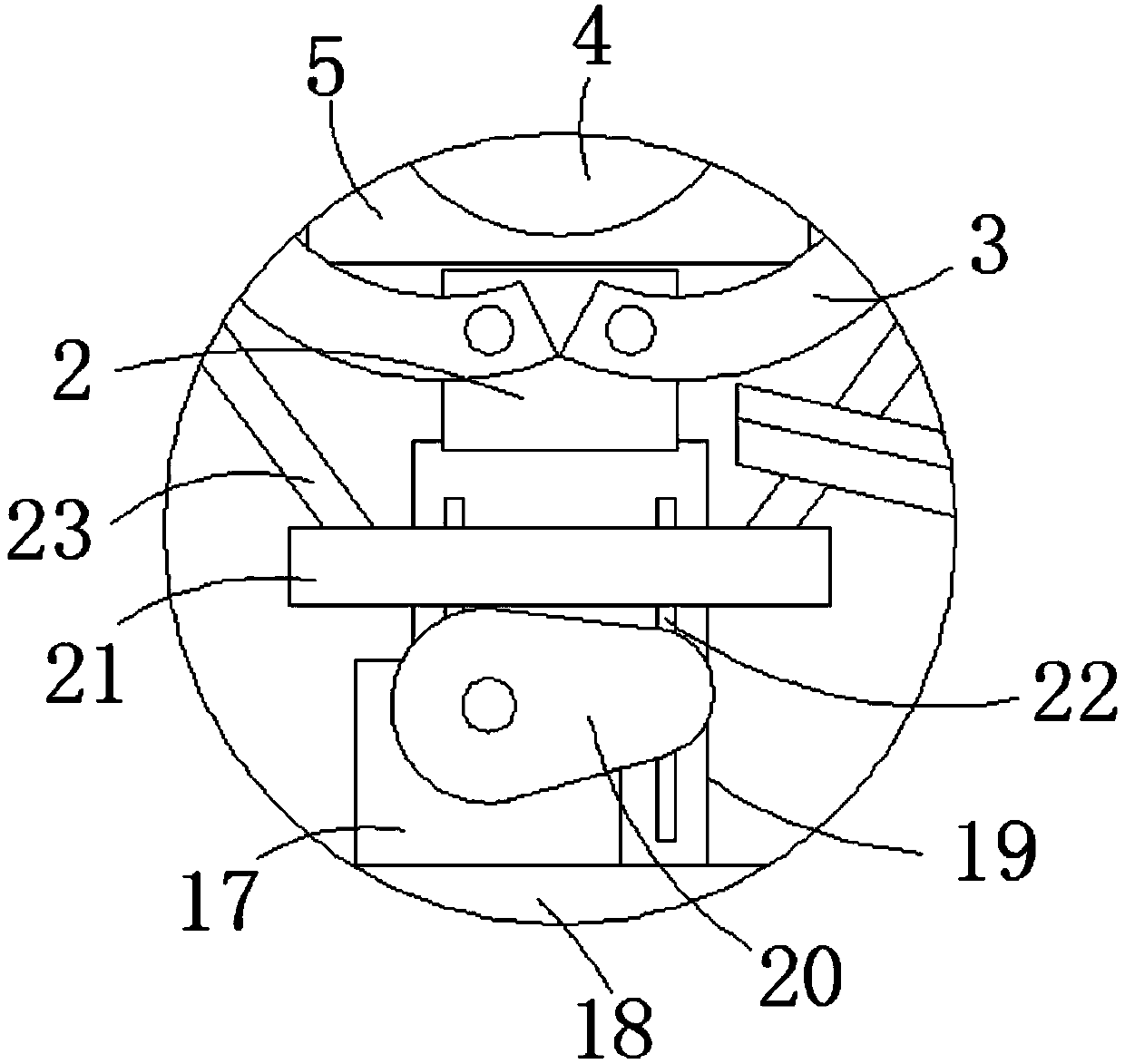

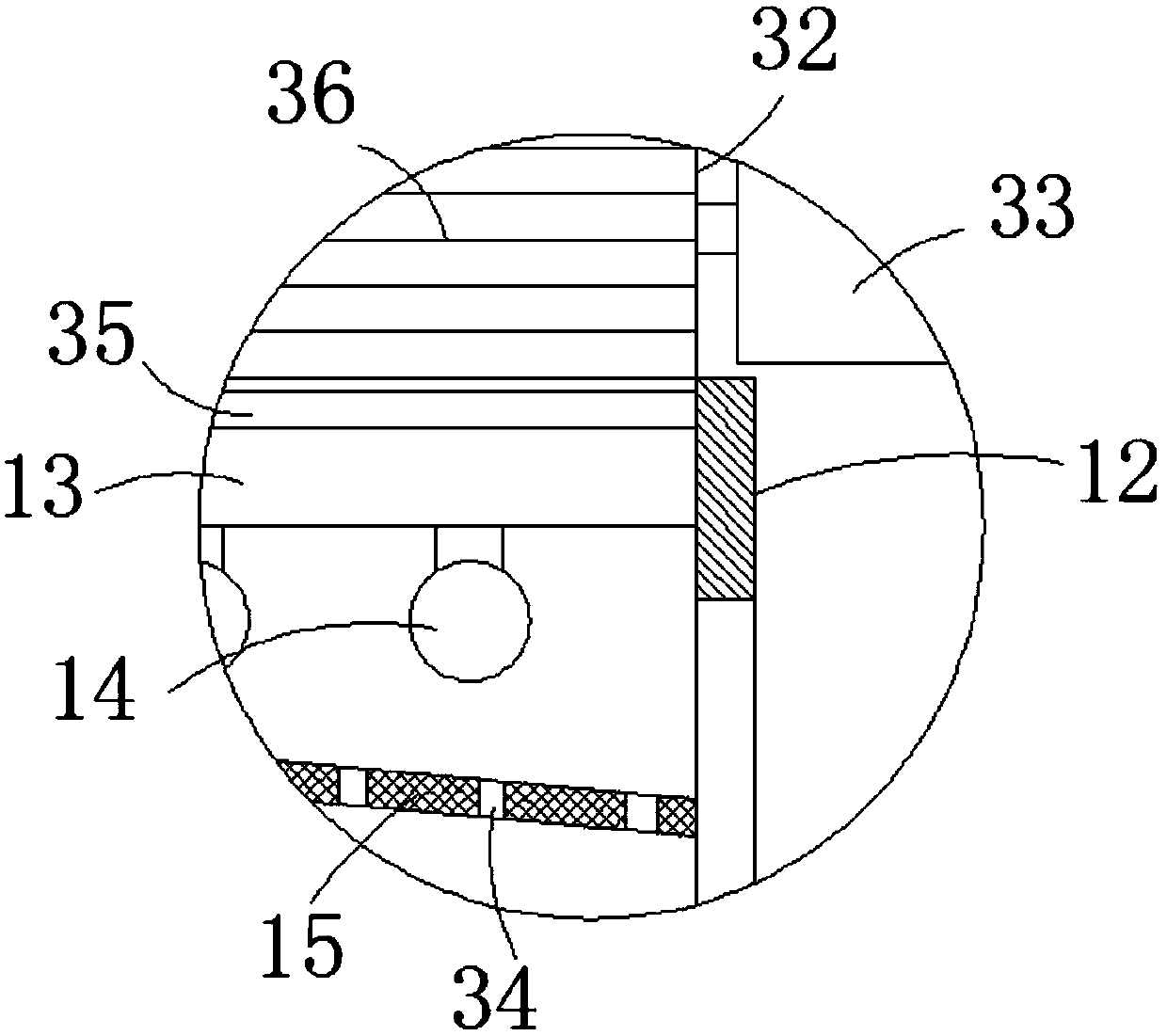

[0022] Such as Figure 1-5 As shown, a paper cup convex groove forming device for a paper cup machine includes a box body 1, a fixed block 2 is fixedly connected to the inner wall of the box body 1, and two forming plates 3 are rotatably connected to the fixed block 2. Specifically, forming The inner side wall of the plate 3 is evenly distributed with protrusions, and the cross section of the protrusions is triangular, which increases the roughness of the side wall of the forming plate 3, and is convenient for placing the paper for making paper cups on the side wall of the forming plate 3. The lower side is provided with a driving mechanism, which drives the rotation of the forming plate 3, and then bends the paper for making paper cups. The upper side of the driving mechanism is provided with a cup phantom 4, and one side of the cup phantom 4 is provided with a back plate 5. The cup phantom 4 Rotationally connected to the side wall of the back plate 5, the side wall of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com