Automatic winding device

A roll material, automatic technology, applied in the direction of thin material processing, winding strips, transportation and packaging, etc., can solve the problems of safety hazards, low work efficiency, etc., to improve efficiency, improve work efficiency, and facilitate removal or replacement quick effect

Active Publication Date: 2019-04-19

宁波隆锐机械制造有限公司

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Commonly used textile machinery also includes a discharge cloth storage device. Before the common discharge cloth is wound up, it is necessary to manually roll the cloth onto the winding roller and then start winding. This poses a certain safety hazard and makes the work less efficient

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

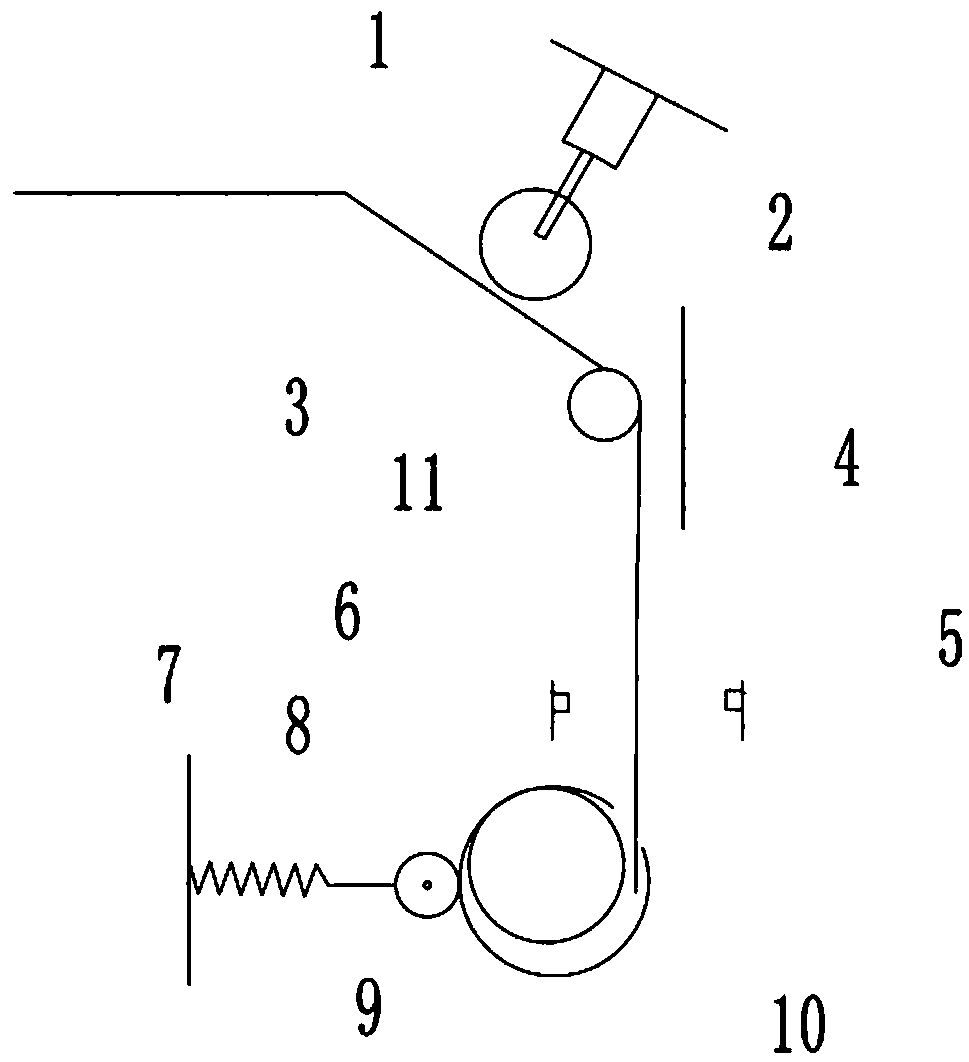

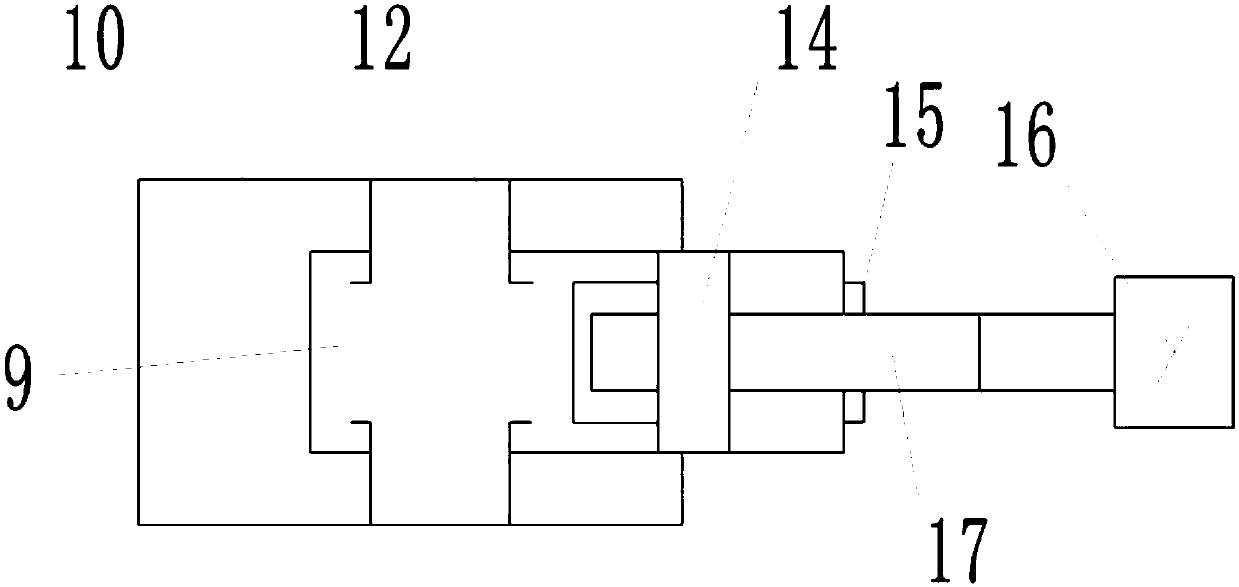

The invention belongs to the technical field of knitted fabric production equipment, and discloses an automatic winding device. The automatic winding device comprises a winding roller, a pressing roller, a conveying roller, a driving motor and a sensor. According to the automatic winding device, a material belt is conveyed to the edge of a feeding table through a feeding roller, the material beltfalls into a winding part under the action of gravity, the sensor senses the falling material belt, and then, the driving motor drives the winding roller to clamp and wind the material belt. Through the scheme, the winding device can wind the material belt automatically.

Description

technical field [0001] The invention belongs to the technical field of knitted fabric production equipment, and in particular relates to an automatic winding device. Background technique [0002] Textile machinery is a variety of mechanical equipment required to process natural fibers or chemical fibers into textiles. Textile machinery in a broad sense also includes chemical machinery for the production of chemical fibers. Textile machinery is the production means and material basis of the textile industry. Its technical level, quality and manufacturing cost are directly related to the development of the textile industry. Commonly used textile machinery also includes a discharge cloth storage device. Before the common discharge cloth is wound up, it is necessary to manually roll the cloth onto the winding roller and then start winding. This poses a certain safety hazard and makes the work less efficient. Contents of the invention [0003] The object of the present inven...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B65H19/28B65H19/30B65H18/26B65H26/00B65H20/02B65H18/10

CPCB65H18/10B65H18/26B65H19/28B65H19/30B65H20/02B65H26/00B65H2701/174

Inventor 王健

Owner 宁波隆锐机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com