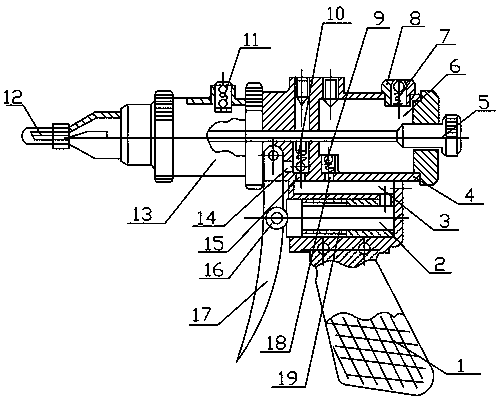

High-pressure oil injection gun

A technology of high-pressure oil injection and high-pressure chamber, which is applied in the direction of lubricating oil control valve, manual lubricant supply, engine components, etc., can solve the problems of insufficient oil filling and low pressure, and achieve the effect of flexible use and high oil injection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0010] As shown in the figure, there is an oil tank 6 at the rear of the housing 4, a high-pressure chamber 13 is left in the middle of the housing 4, a main plug oil pump 2 is installed on the upper part of the handle 1, and a roller 16 is installed at the middle of the trigger 17. Plug oil pump 2 front ends contact with the roller 16 of trigger 17 middle parts, and axial long rod oil control valve 5 is housed in the middle of housing 4 rear ends, and housing 4 front ends leave oil injection nozzle 12. There is an oil filling hole plug 8 and an air intake valve 7 on the top of the fuel tank 6, an oil suction port 18 and a single oil suction valve 9 are left on the bottom of the fuel tank 6, a safety valve 11 is installed on the high pressure chamber 13, and the high pressure chamber 13 An oil passage 14 is left at the rear to communicate with the oil d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap