Method of manufacturing composite material window

A composite material and manufacturing method technology, applied in the installation of window glass, windows/doors, window/door frames, etc., can solve problems such as low productivity, and achieve the effects of increasing productivity, reducing manufacturing costs, and improving water tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will now be described in more detail with reference to the following examples.

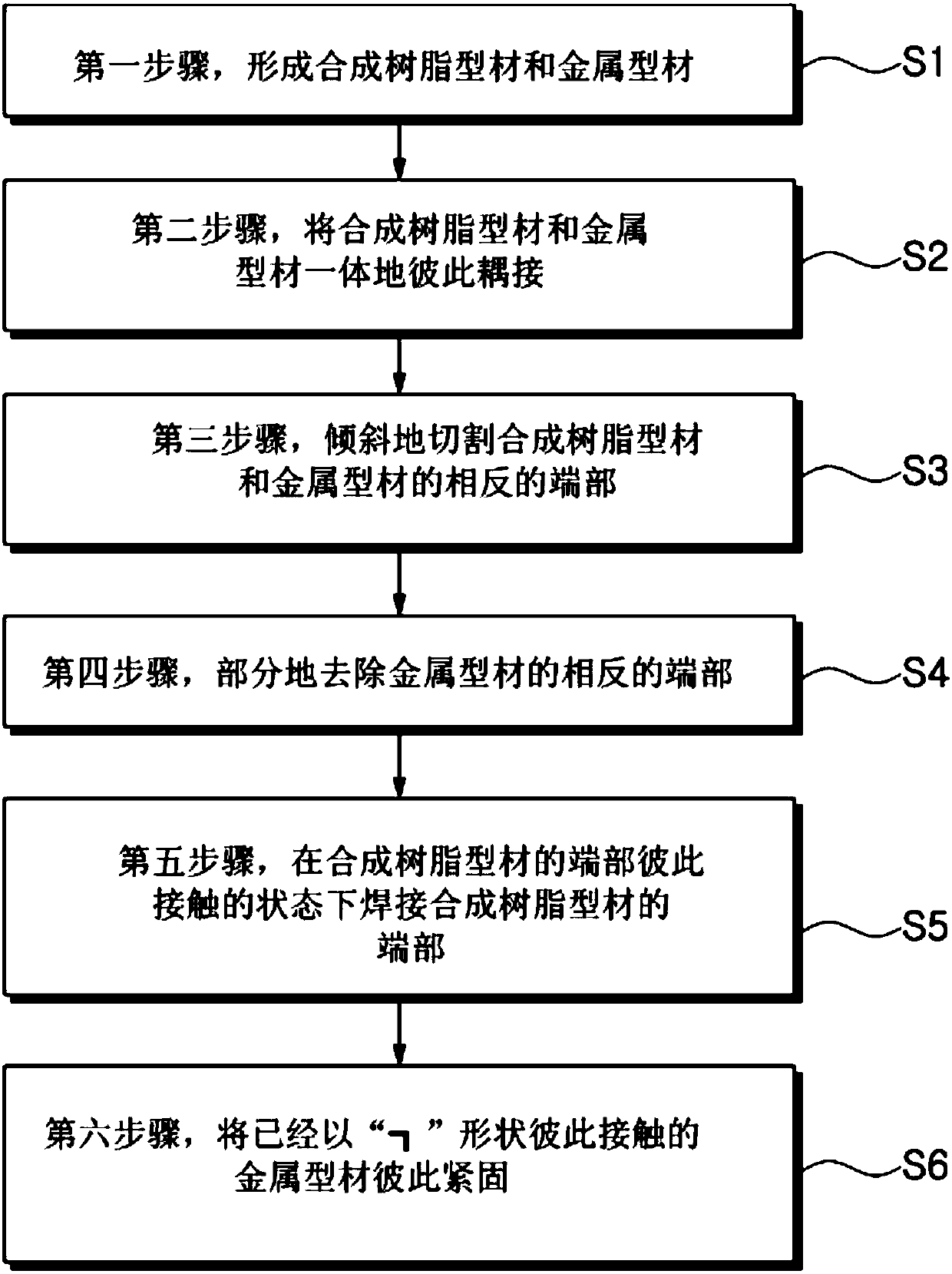

[0050] Such as figure 1 As shown, the manufacturing method of the composite material window according to the present invention comprises a first step (S1), a second step (S2), a third step (S3), a fourth step (S4), a fifth step (S5) and a Six steps (S6).

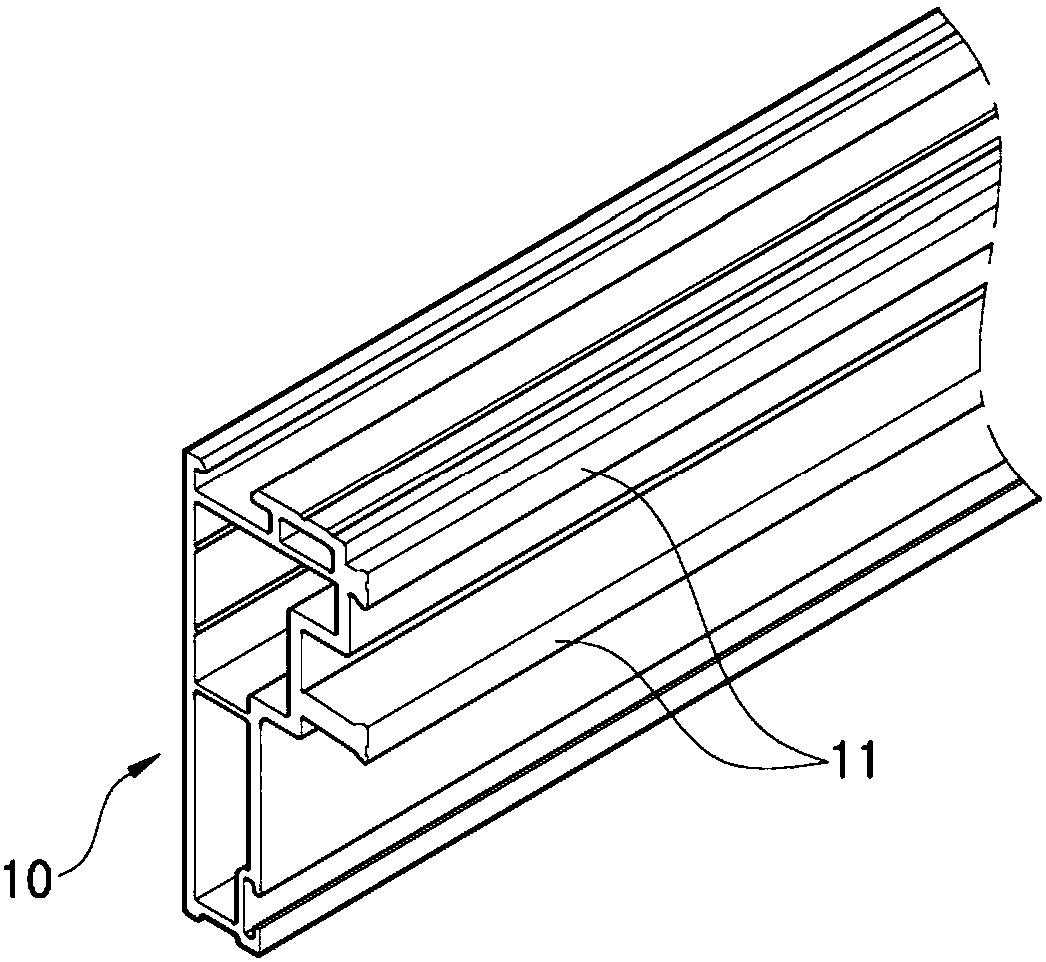

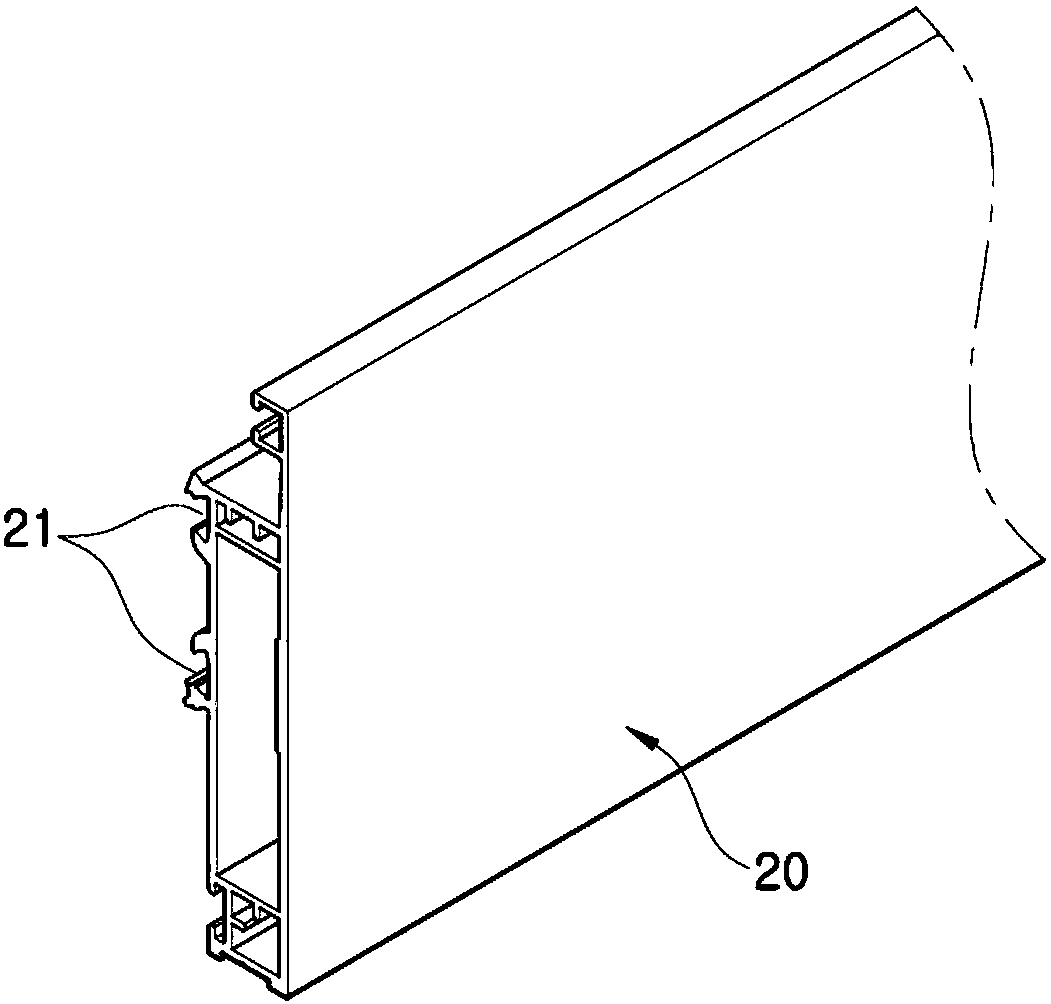

[0051] In the first step (S1), a synthetic resin profile 10 having a protrusion 11 formed on one surface thereof and a metal profile 20 having a groove 21 formed in one surface thereof are formed.

[0052] In the first step (S1), the synthetic resin profile 10 may be made of polyvinyl chloride (PVC).

[0053] Since the synthetic resin profile 10 is made of polyvinyl chloride, the durability and heat insulation value of the window frame 100 and the sash 200 may be improved.

[0054] In the first step ( S1 ), the protrusion 11 is integrally formed on the synthetic resin profile 10 in the longitudinal direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com