Vibration discharging plate frame type slurry press filter

A plate and frame type, filter press technology, applied in filtration and separation, sludge treatment, water/sludge/sewage treatment, etc., can solve troublesome time-consuming and laborious, secondary pollution of water and air, unfavorable sludge incineration treatment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

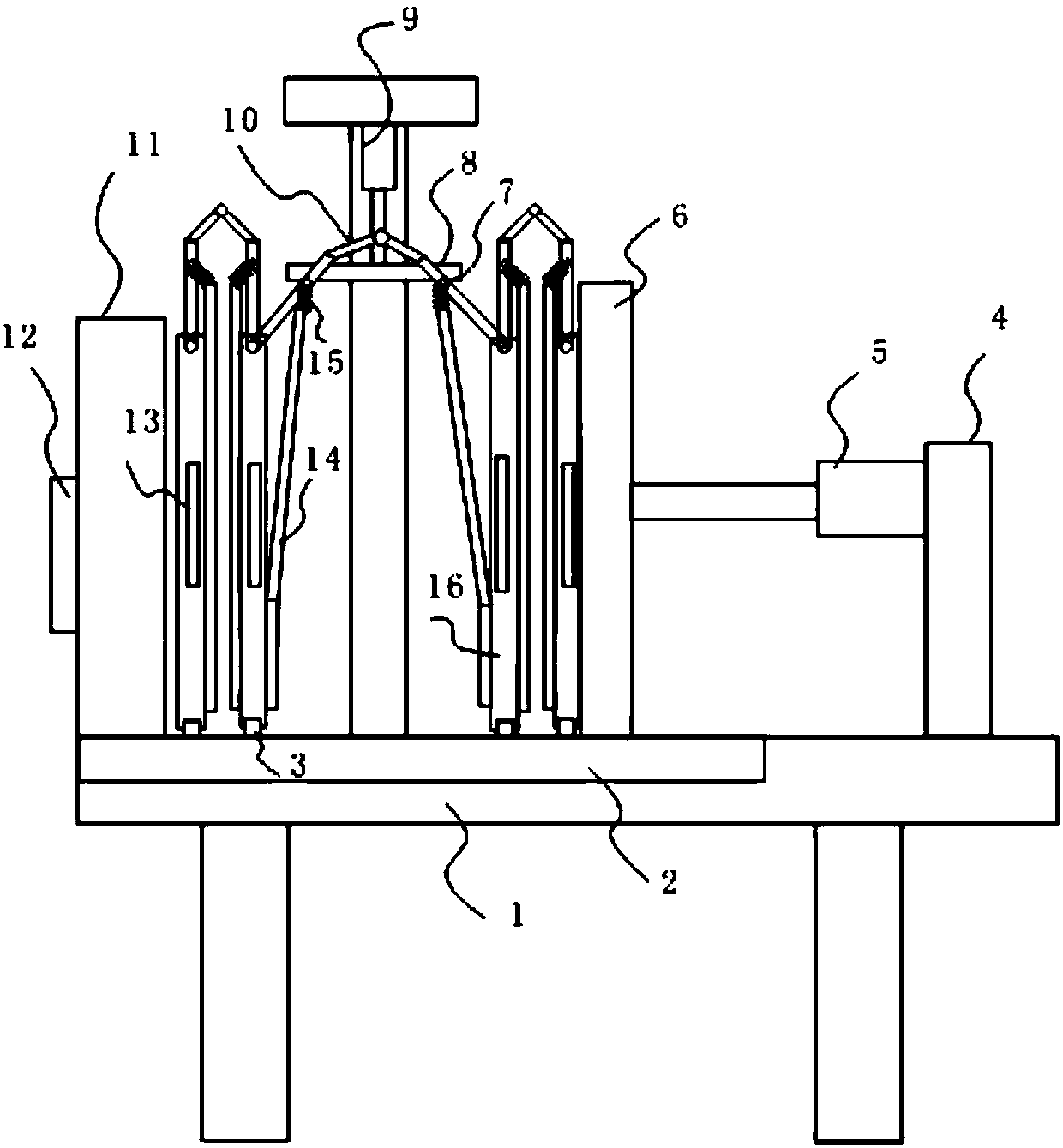

[0012] A plate and frame mud filter press for vibrating discharge, which includes a frame 1, a filter press device, a compacting device and a vibrating device, and the filter press device includes a plurality of filter frames 16 and filter frames installed on both sides of the filter frame Filter plate 14, the two sides of the frame are provided with slide rails 2 along the extension direction, on which slide brackets 3 are installed, and the bottom of the filter frame is installed on the slide brackets, the filter plate is made of elastic material, the filter plate The lower part is fixedly installed with the filter frame, and the top of each filter frame is hinged with two connecting rods 10, and the upper part of each connecting rod is provided with a bend, and one of the connecting rods is hinged with a connecting rod of the front filter frame at the top, and the other A connecting rod and a connecting rod of the rear filter frame are hinged at the top, a spring 15 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com