Spiral tooth feeding millstone of natural hard stone

A grinding disc and spin technology, applied in cocoa, grain processing, food science, etc., can solve the problems of not being able to dissipate heat, burning powder and reducing food quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] specific implementation

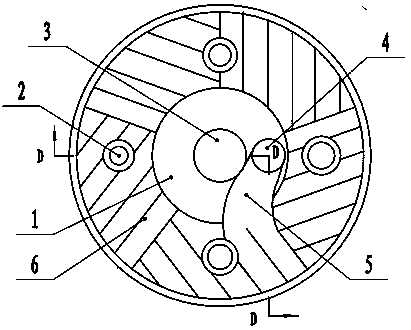

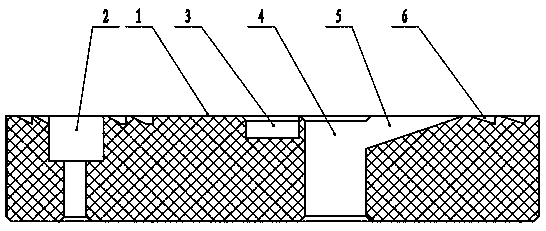

[0009] A bearing hole 3 is drilled in the center of the plane inner disc 1, the locking hole 2 is drilled on the grinding disc for locking and fixing, the bearing hole 3 is drilled on the center of the plane inner disc, the feed hole 4 is drilled on the plane inner disc 1, and the feed groove 5 chain feed hole 4 opens out the chute, and the spiral helical tooth 6 divides the grinding disc into five equal parts, and takes the radius line as the baseline along the feeding groove 5 to form the grinding surface of the grinding disc, and the grinding surface of the grinding disc is discharged from the other half The grinding discs cooperate to start the power, and the food enters from the feeding hole 3 and starts to refine and grind through the feeding groove 5. The helical helical teeth 6 not only refine the pulp and grind finely, but also play the role of ventilation and heat dissipation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com