Method for dissociating plant fiber secondary wall S2 layer

A plant fiber and secondary wall technology, applied in the direction of fiber raw materials, fiber raw material processing, cellulose raw material pulping, etc., can solve the problems of destroying the structure of plant fiber tissue, the inability to use the space structure, and the complexity of mechanical operations, etc., to achieve high efficiency Effects of chemical modification, reduction of residues of chemical toxic substances, and utilization of high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

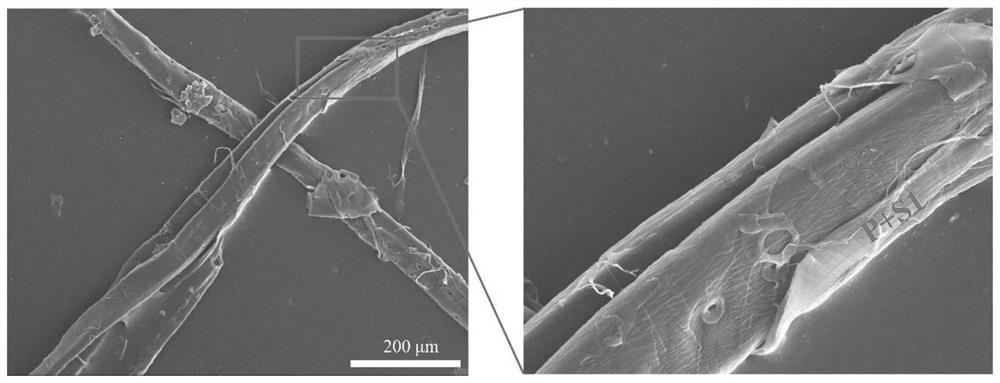

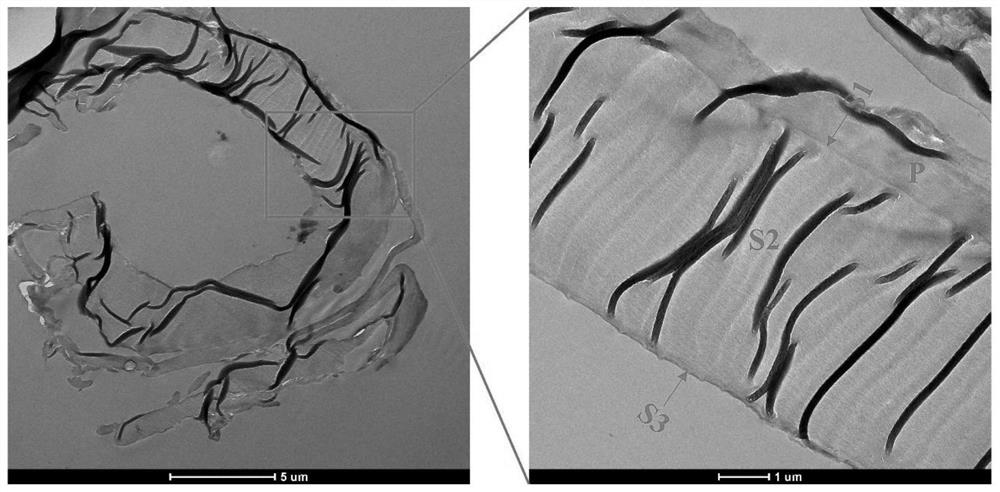

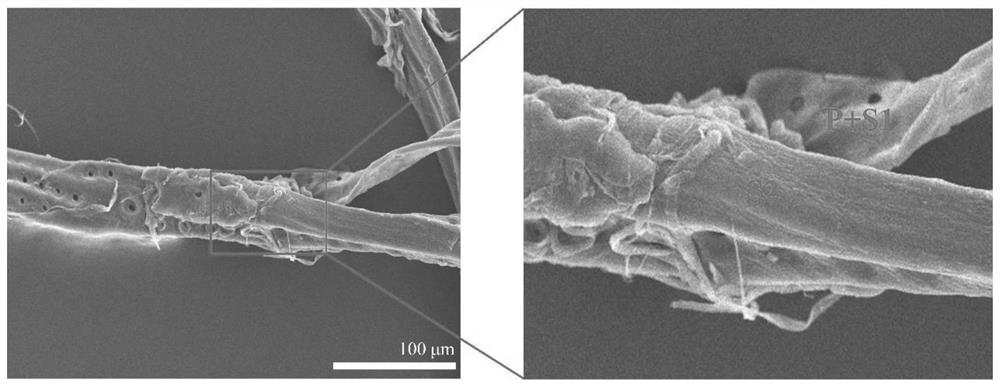

[0045] A 20cm-thick Chi fir disc was crushed with a pulverizer, and the crushed wood samples were soaked in water for 12 hours, filtered after soaking, and the filtered wood samples were placed in a double-screw extruder for thawing until they passed through a 2cm sieve. 17.5% of the dry weight of the plant sample in NaOH solution, 10% of the dry weight of the plant sample in H 2 o 2 solution, 1.5% Na by dry weight of plant samples 2 SiO 3 9H 2 O solution, the chelating agent diethyltriaminepentaacetic acid of 0.2% of plant sample dry weight is mixed evenly and joins in the extruded pond fir wood sample (wood moisture content 25%) of 1.5kg absolutely dry, and mixes Evenly, and then put it in a disc mill (speed: 3000r / min, disc grinding distance 0.5mm) for 5min, put it in a high temperature resistant bag and seal it, and keep it in an oven at 95°C for 1h. After the heat preservation is over, plant samples Dissociate in a disc mill (rotational speed: 3000r / min, disc grinding...

Embodiment 2

[0047] A 20cm-thick Chi fir disc was crushed with a pulverizer, and the crushed wood samples were soaked in water for 12 hours, filtered after soaking, and the filtered wood samples were placed in a double-screw extruder for thawing until they passed through a 2cm sieve. 17.5% of the dry weight of the plant sample in NaOH solution, 12% of the dry weight of the plant sample in H 2 o 2 Solution, 1.8% Na by dry weight of plant samples 2 SiO 3 9H 2 O solution, the chelating agent diethyltriaminepentaacetic acid of 0.3% of the plant sample dry weight is mixed uniformly and then added to 1.5kg of absolutely dry extruded pond fir wood samples (wood moisture content 25%), and mixed Evenly, and then put it in a disc mill (speed: 3000r / min, disc grinding distance 0.5mm) for 5min, put it in a high temperature resistant bag and seal it, and keep it in an oven at 95°C for 1h. After the heat preservation is over, plant samples Dissociate in a disc mill (rotational speed: 3000r / min, disc...

Embodiment 3

[0049] A 20cm-thick Chi fir disc was crushed with a pulverizer, and the crushed wood samples were soaked in water for 12 hours, filtered after soaking, and the filtered wood samples were placed in a double-screw extruder for thawing until they passed through a 2cm sieve. 17.5% of the dry weight of the plant sample in NaOH solution, 16% of the dry weight of the plant sample in H 2 o 2 solution, 2% Na by dry weight of plant samples 2 SiO 3 9H 2 O solution, the chelating agent diethyltriaminepentaacetic acid of 0.3% of the plant sample dry weight is mixed uniformly and then added to 1.5kg of absolutely dry extruded pond fir wood samples (wood moisture content 25%), and mixed Evenly, and then put it in a disc mill (speed: 3000r / min, disc grinding distance 0.5mm) for 5min, put it in a high temperature resistant bag and seal it, and keep it in an oven at 95°C for 1h. After the heat preservation is over, plant samples Dissociate in a disc mill (rotational speed: 3000r / min, disc g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com