Corrugated board grooving machine

A technology of corrugated cardboard and slotting machine, which is applied in paper/cardboard containers, papermaking, container manufacturing machinery, etc. It can solve the problems of inappropriate indentation and scoring lines, easy bursting of corrugated paper indentation and scoring lines, and inaccurate distance between creasing wheels. to automatic adjustment and other issues to achieve the effect of flexible production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

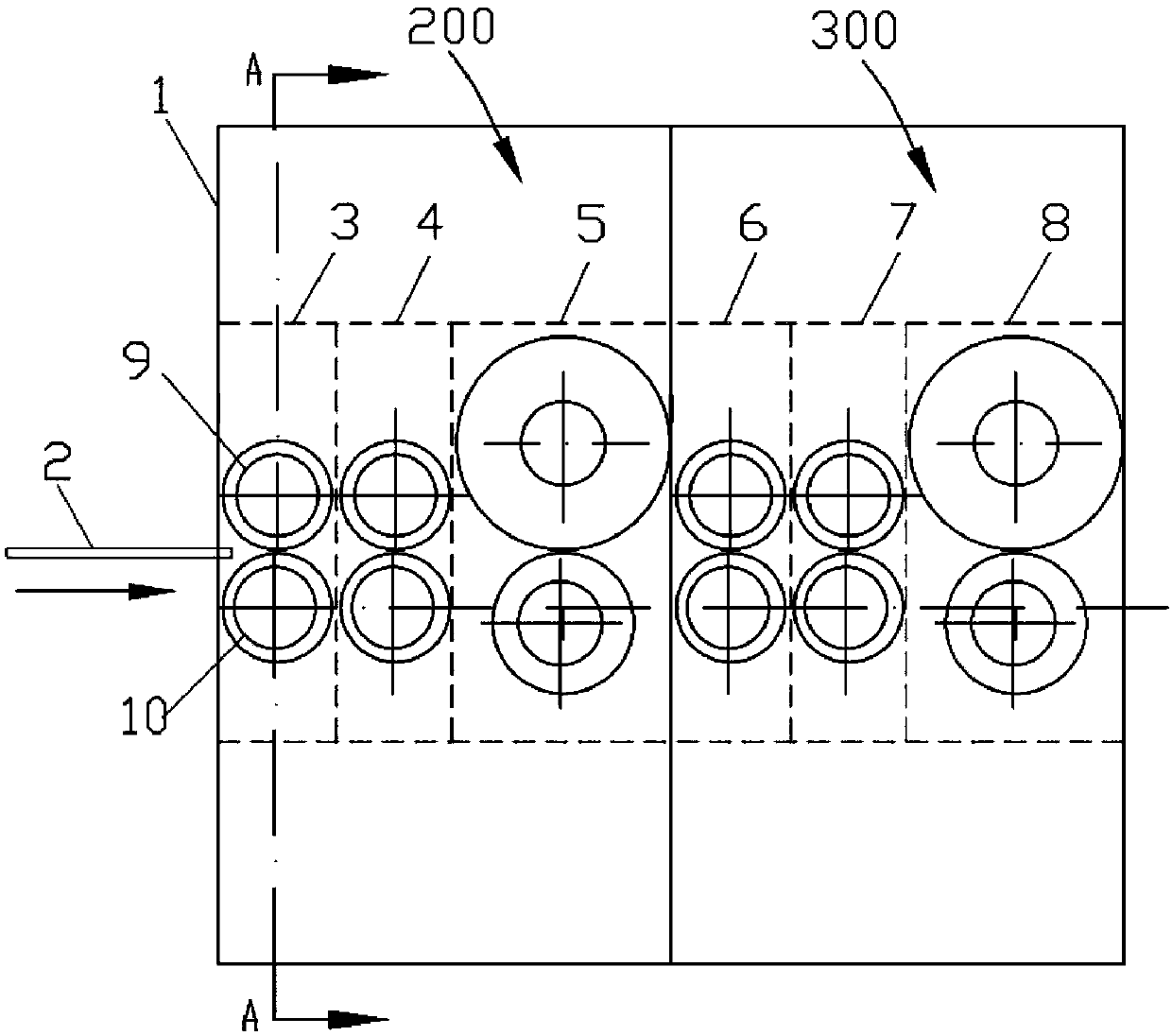

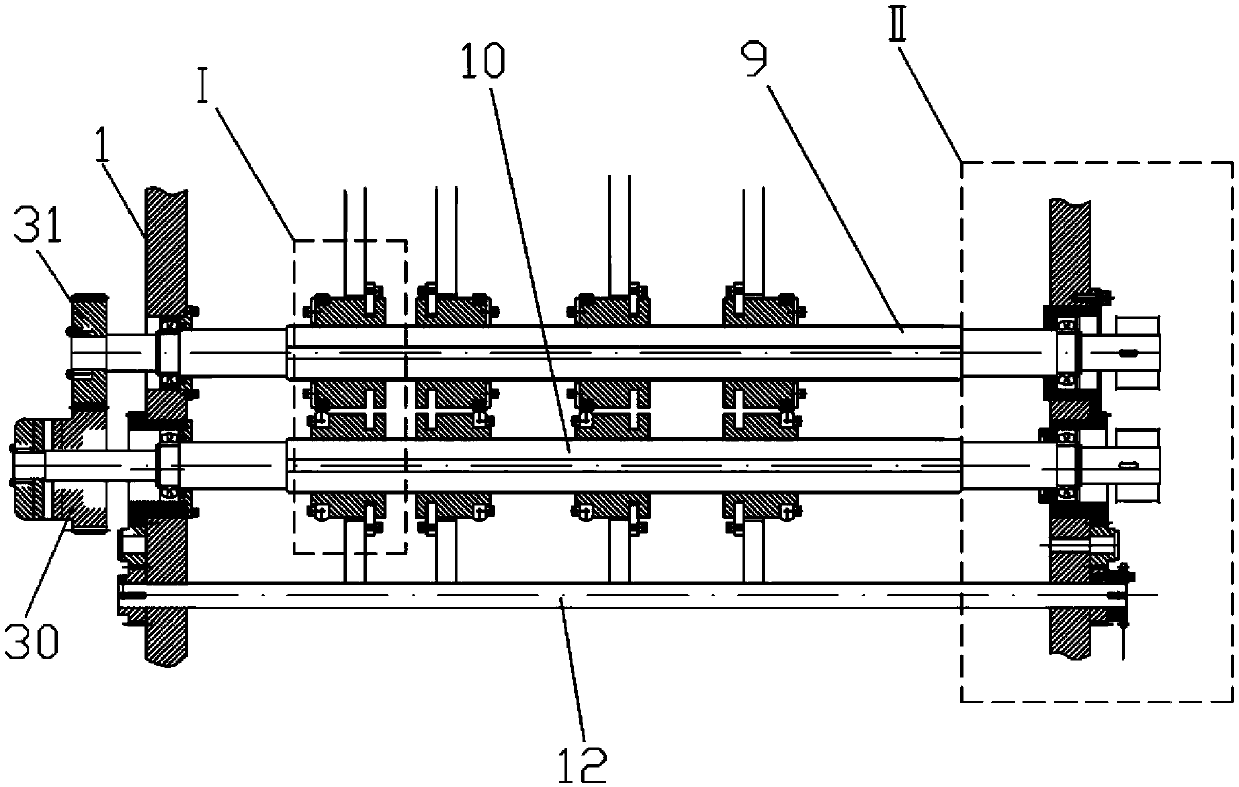

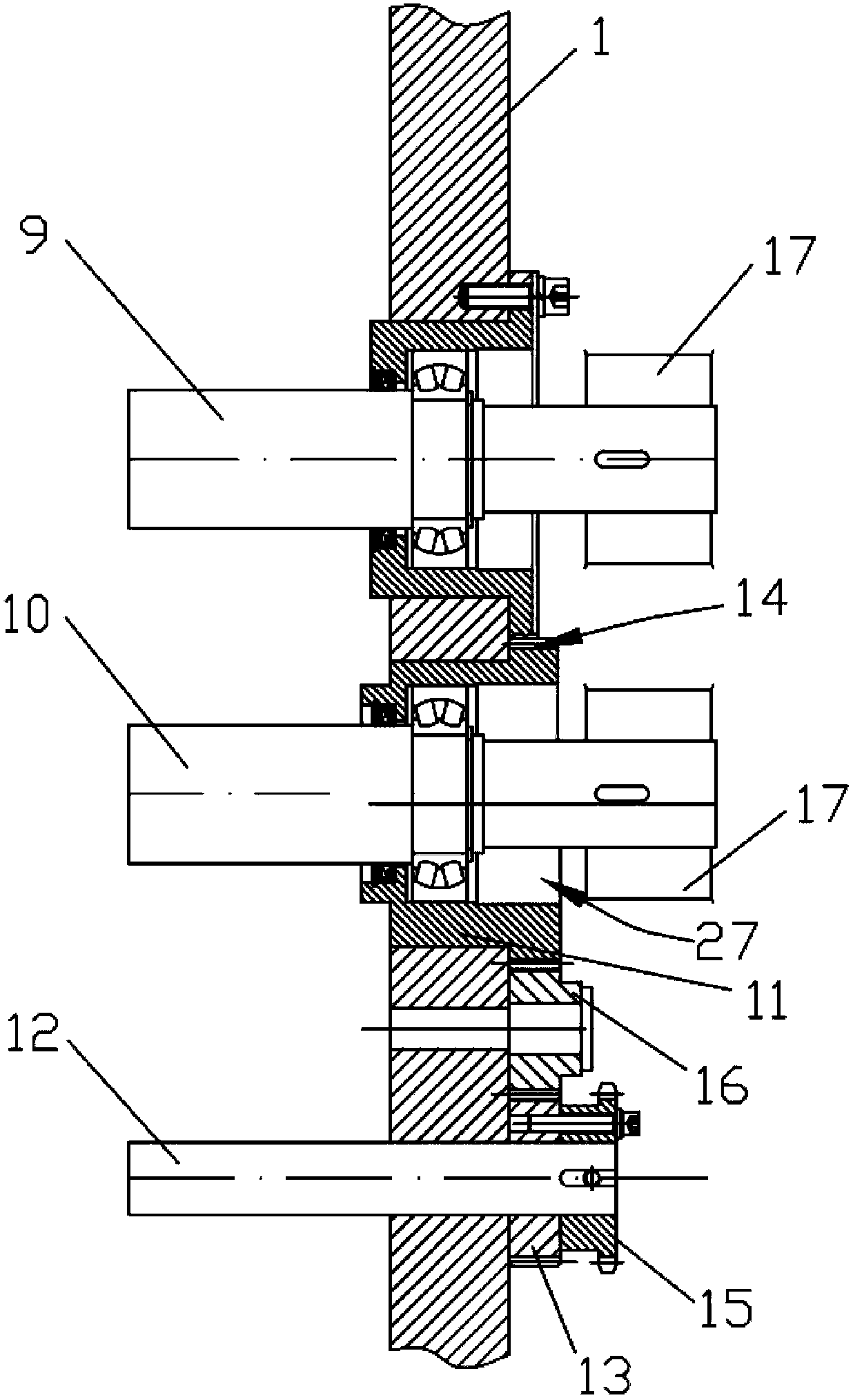

[0023] Such as Figure 1-Figure 4 As shown, the present invention discloses a corrugated cardboard slotting machine, which includes a pre-press slotting part 200 and a press-line slotting part 300 installed on a frame 1. A pre-pressing wheel set 3, a second pre-pressing wheel set 4 and a first grooving wheel set 5. The creasing and grooving part 300 includes corrugated paper 2 passing through the first creasing wheel set 6, the second creasing wheel set 7 and The second grooving wheel group 8, the output end of the first grooving wheel group 5 is connected to the input end of the first creasing wheel group 6, that is, the corrugated paper 2 enters from the first pre-pressing wheel group 3 and finally passes through the second grooving wheel group. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap