Multilayer tube internal layer polymer composite material for automobile fuel pipes, and preparation method thereof

A composite material and multi-layer tube technology, applied in the field of automotive materials, can solve the problems of not being able to burn like gasoline, affecting the performance and life of the engine, and avoiding the formation and accumulation of carbon deposits and the formation of carbon deposits in the combustion chamber of the engine. , the effect of good low temperature performance and high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

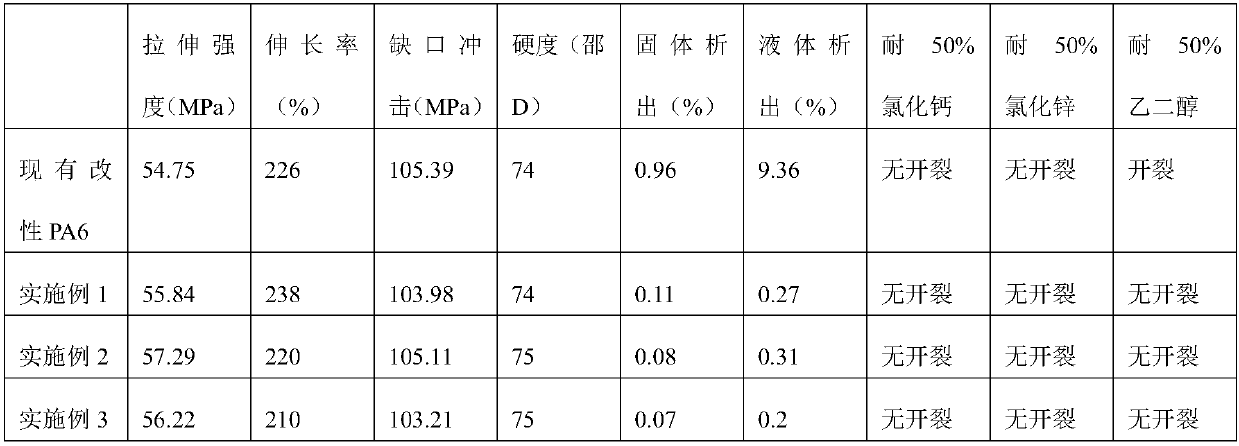

Embodiment 1

[0012] Example 1: The present invention relates to a polymer composite material for the inner layer of a multilayer tube for automobile fuel pipes. The inner layer material includes the following components in parts by weight: 50 parts of nylon resin, 10 parts of PE, 5 parts of EVM, corresponding 10 parts of solvent, 1 part of additives; the nylon resin is PA510 (relative viscosity 4.4~4.8), PE is linear low density polyethylene, and the EVM is ethylene vinyl acetate copolymer, wherein the content of vinyl acetate is not Less than 40%; the adjuvant is selected from a mixture of antioxidants, chain extenders and end-capping agents in any ratio; the phase solvent is PE-g-MAH or POE-g-GMA.

[0013] The method for preparing the polymer composite material of the inner layer of the multilayer tube for automobile fuel pipe includes the following steps:

[0014] (1) Weigh each component according to the ratio;

[0015] (2) Add nylon resin, PE, EVM, phase solvent and auxiliary agent to the m...

Embodiment 2

[0017] Example 2: The difference from Example 1 is that the nylon resin is 60 parts, PE 15 parts, EVM 8 parts, phase solvent 15 parts, and auxiliary agent 2 parts. The phase solvents are SEBS-g-MAH and SEBS-g-GMA, and the preparation method of the polymer composite material for the inner layer of the multilayer tube for automobile fuel pipe includes the following steps: (1) Weigh each component according to the proportion; 2) Sequentially add nylon resin, PE, EVM, phase solvent and additives to the mixer, mix evenly and then extrude and granulate through a twin-screw extruder. In the step (2), the stirring temperature is room temperature, the stirring speed is 400 rpm, and the stirring time is 10 minutes; the screw speed of the twin-screw extruder is 300 rpm, and the mixture formed by each component is stirred After homogenization, it passes through nine zones of the twin-screw extruder and then extrudes. The temperature of each zone is 200℃ in one zone, 210℃ in two zone, 220℃ ...

Embodiment 3

[0018] Example 3: The difference from Example 1 is that the inner polymer composite material includes the following parts by weight: 70 parts of nylon resin, 30 parts of PE, 10 parts of EVM, 30 parts of phase solvent, additives 5 parts; the phase solvent is selected from one of PE-g-MAH, POE-g-GMA, SEBS-g-MAH, SEBS-g-GMA. The preparation method of the polymer composite material for the inner layer of the multilayer pipe for automobile fuel pipe includes the following steps: (1) Weigh each component according to the proportion; (2) sequentially add nylon resin, PE, EVM, phase solvent and additives to the mixer , After mixing evenly, it is extruded and granulated through a twin-screw extruder. In the step (2), the stirring temperature is room temperature, the stirring speed is 400 rpm, and the stirring time is 10 minutes; the screw speed of the twin-screw extruder is 320 rpm, and the mixture formed by each component is stirred After homogenization, it passes through nine zones o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com