Production method for high-definition dual-color DTY complex fiber

A production method and technology of composite fibers, applied in textiles, papermaking, yarn and other directions, can solve the problems of turbidity and insufficient definition, and achieve the effects of clear and high definition, cost saving and production time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take 75D / 72F black polyester pre-oriented yarn as (A), and 75D / 72F white polyester pre-oriented yarn as (B).

[0023] Produced on the texturing machine Murata 33H-S+Z machine, the two kinds of raw materials are processed through the normal silk path until the two kinds of silk enter the two silk path weighting networks of the double-groove nozzle chip at the middle roller, and then pass through the lower heat Box shaping, two yarns enter a nozzle at the bottom roller at the same time and increase the air pressure of the network to combine the two yarns into one strand. The preparation process parameters are as follows: vehicle speed 600m / min, draft 1.65, speed ratio 1.70, upper hot box temperature 190°C, lower hot box temperature 185°C, second overrun 3.27%, third overrun 3.49%, middle roller nozzle TG105 (double tank Nozzle), middle roller air pressure 0.4Mpa, bottom roller nozzle TG212, bottom roller network air pressure 0.42Mpa, obtain high-definition two-color DTY c...

Embodiment 2

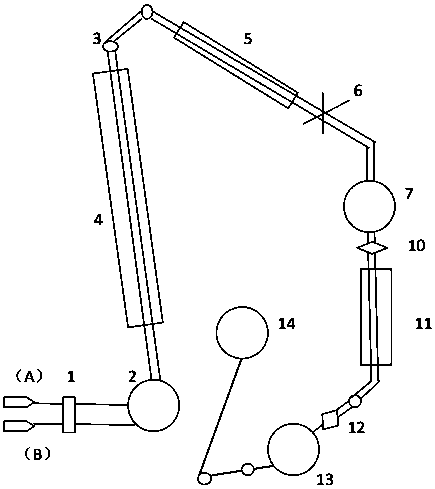

[0026] Taking 75D / 72F cationic polyester pre-oriented yarn as (A) and 75D / 72F white polyester pre-oriented yarn as (B), the production schematic diagram is as follows figure 1 As shown, the texturizing machine is produced on the Barmag S+Z machine, and the two raw materials are processed in the normal silk path until the two kinds of silk enter a nozzle at the middle roller and increase the network air pressure (install two network pipes) ), and then go through the lower heat box to shape, the two wires enter a nozzle at the bottom roller at the same time and increase the air pressure of the network (add a network pipe), compound the two strands of yarn into one strand. The preparation process parameters are as follows: vehicle speed 550m / min, drafting 1.66, speed ratio 1.82, upper hot box temperature 155°C, lower hot box temperature 135°C, second super-4.0%, third super-4.4%, middle roller nozzle P142, The air pressure of the middle roller is 0.35Mpa, the nozzle of the bottom...

Embodiment 3

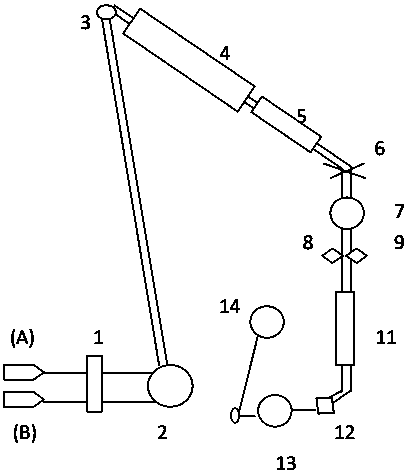

[0029] Taking 150D / 48F cationic polyester pre-oriented yarn as (A), and 150D / 96F white polyester pre-oriented yarn as (B), the production schematic diagram is as follows figure 2 As shown, the texturizing machine is produced on the Barmag S+Z machine, and the two raw materials are processed in the normal silk path until the two kinds of silk enter a nozzle at the middle roller and increase the network air pressure (install two network pipes) ), and then go through the lower heat box to shape, the two wires enter a nozzle at the bottom roller at the same time and increase the air pressure of the network (add a network pipe), compound the two strands of yarn into one strand. The preparation process parameters are as follows: vehicle speed 550m / min, drafting 1.66, speed ratio 1.82, upper hot box temperature 155°C, lower hot box temperature 135°C, second super-4.0%, third super-4.4%, middle roller nozzle TG212, The air pressure of the middle roller is 0.35Mpa, the nozzle of the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com