Outer sprayer of integrated excavator

A sprayer and fully mechanized excavator technology, applied in the field of production equipment, can solve the problems of difficult replacement and maintenance, poor atomization effect, damaged nozzles, etc., and achieve the effects of good atomization effect, reduction of dust generation, and shortening of time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

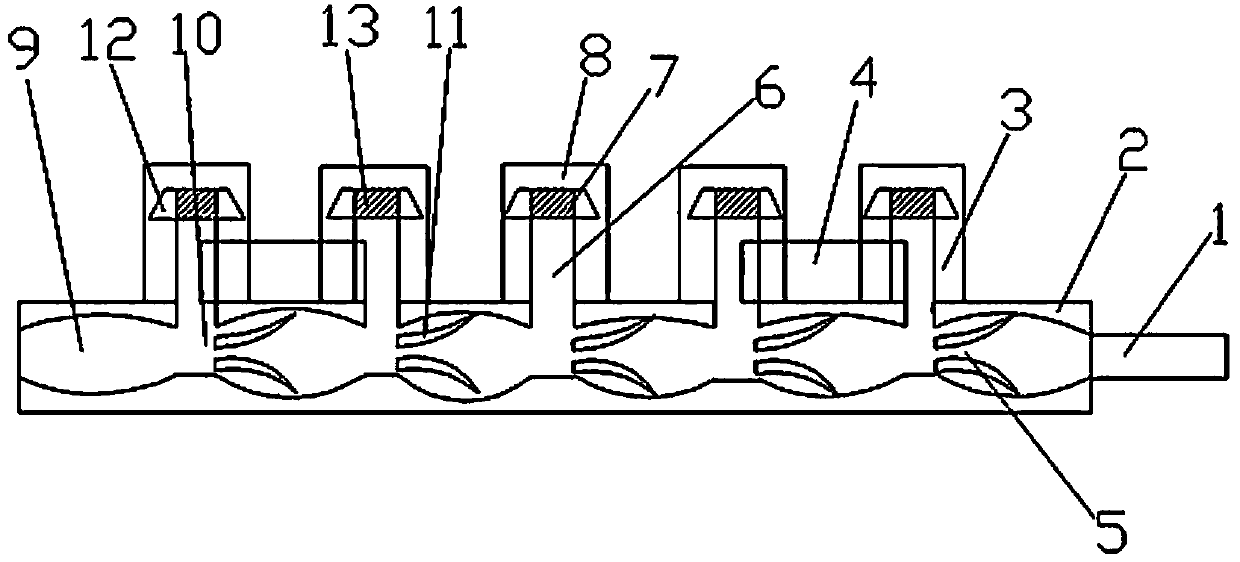

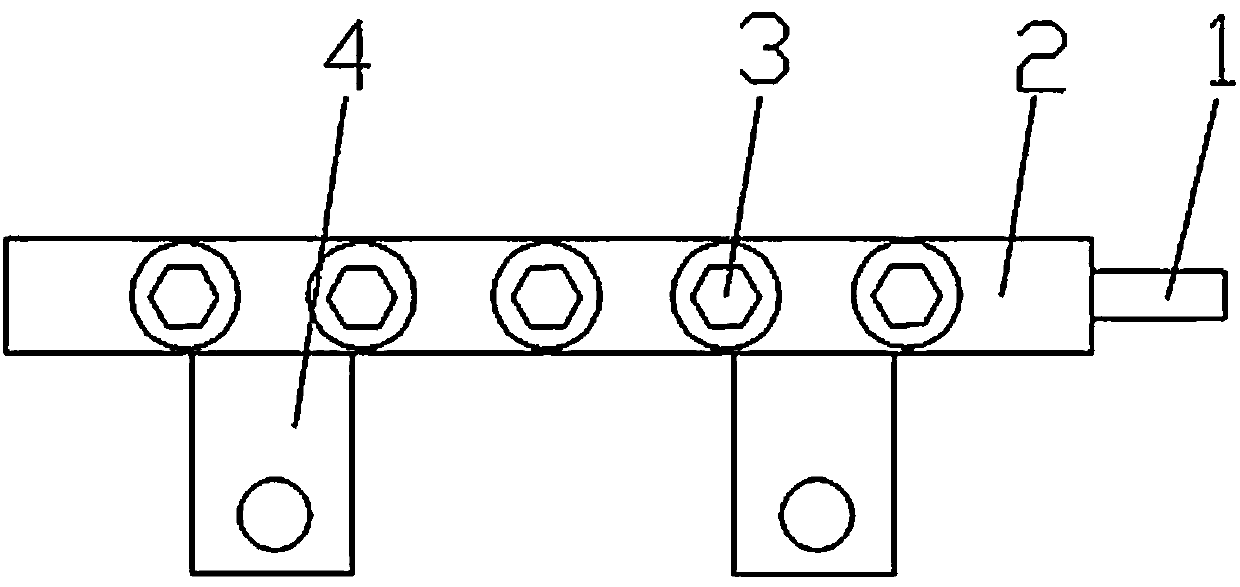

[0014] Figure 1-2 Show the specific embodiment of the present invention: a kind of fully mechanized excavator external sprayer, comprise combination joint 1, seamless steel pipe 2, spray device 3, install side lug 4 and inner bile pipe body 5, inner bile pipe body 5 is arranged on seamless steel pipe 2 Inside, several spraying devices 3 are arranged side by side on the surface of the seamless steel pipe 2, the spraying devices 3 are connected to the inner bile duct body 5, the combined joint 1 is connected to one end of the seamless steel pipe 2, and connected to the inner bile duct body 5, the spraying device 3 Including steel pipe wire head 6, spray head 7 and protective cover 9, a number of steel pipe wire 6 heads are arranged on the seamless steel pipe 2, connected to the inner tube body 5, the spray head 7 is arranged on the steel pipe wire head 6, and the protective cover 8 is nested and arranged On the spray head 7, the inner bile duct body 5 includes a spherical secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com