Friction wear test machine

A friction and wear test, frame technology, applied in the direction of testing wear resistance, etc., can solve the problems of jumping phenomenon, pressure can not be adjusted, affecting observation, etc., to avoid jumping, accurate test results, and reduce investment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

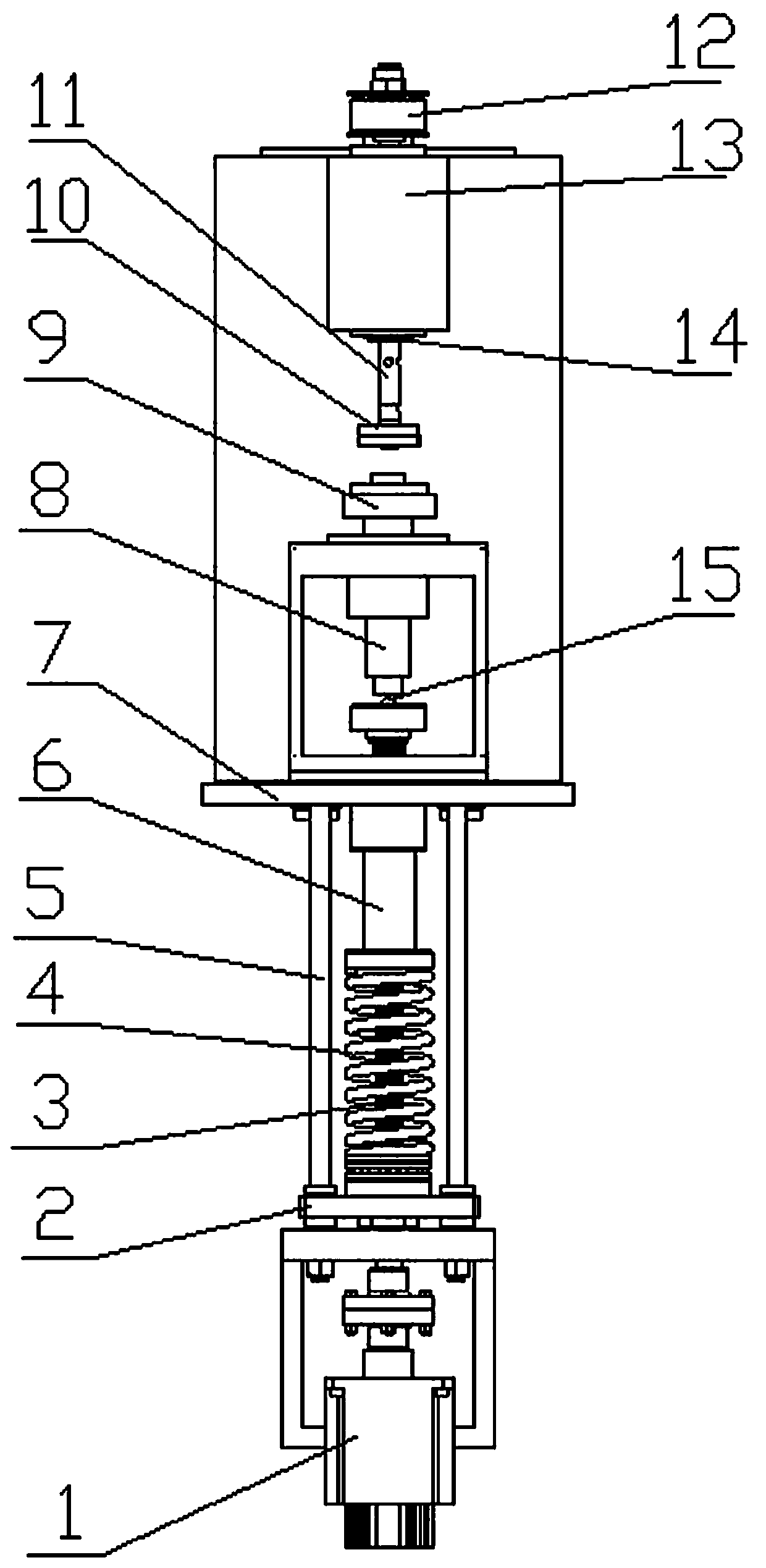

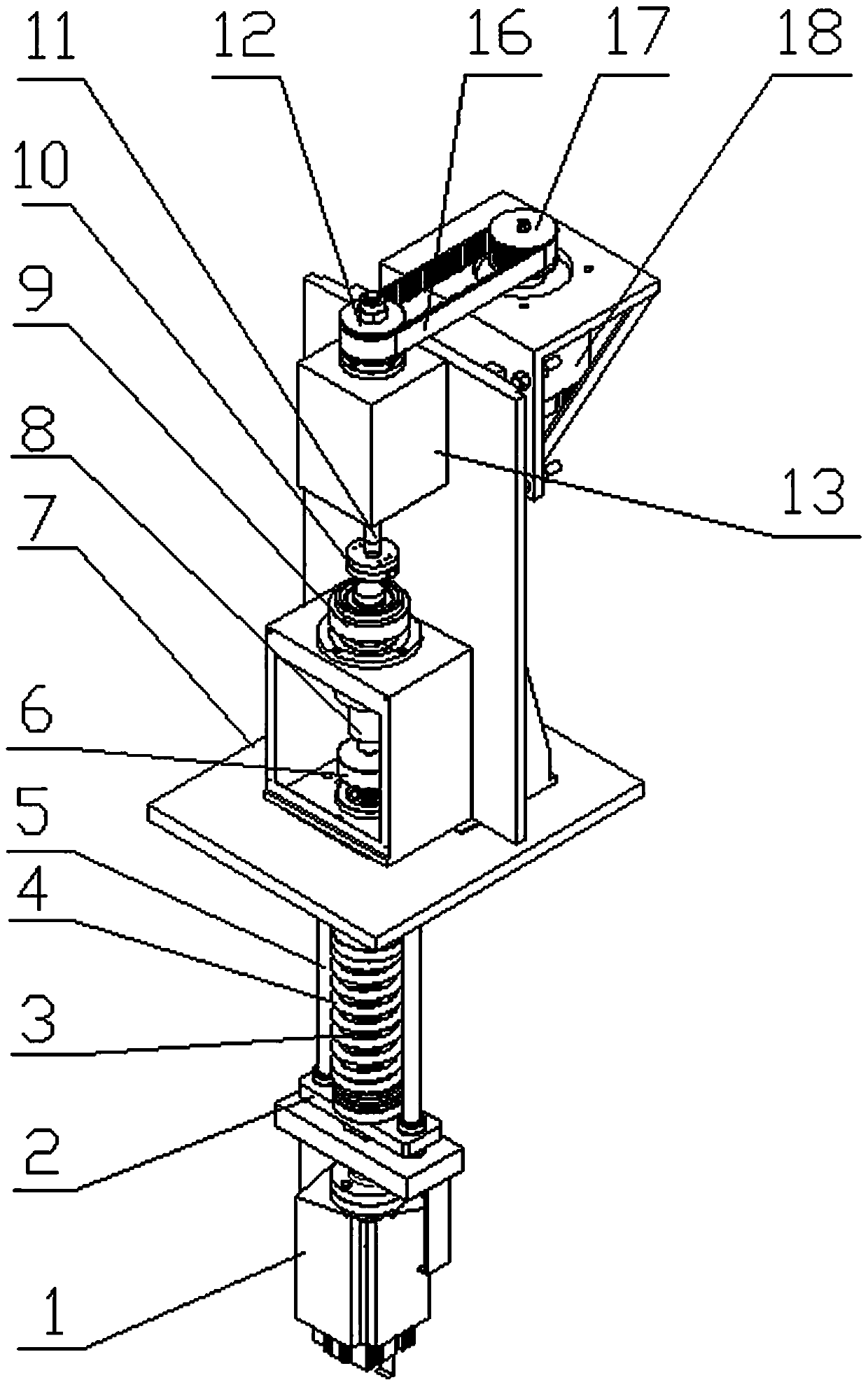

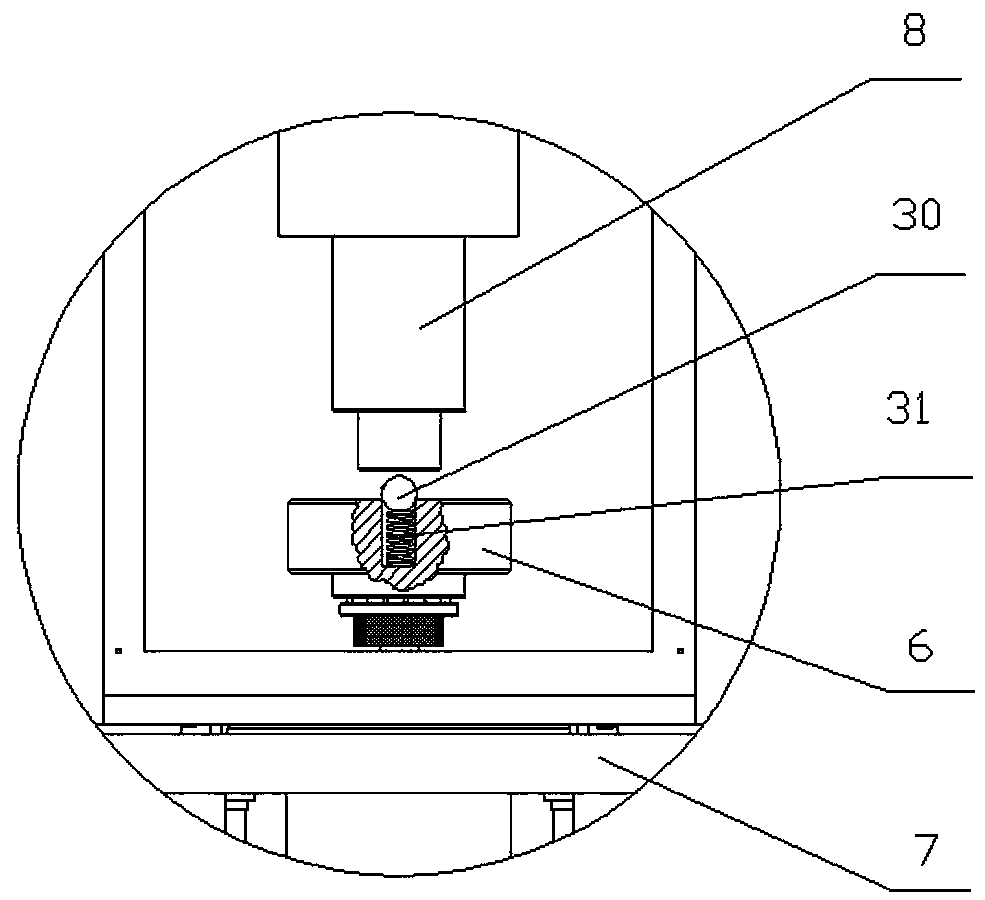

[0029] like Figure 1 to Figure 9 As shown, a friction and wear testing machine of the present invention includes a frame 7 and a rotating shaft 11 and a lifting shaft 8 coaxially arranged on the frame 7 along the vertical direction. The rotary shaft 11 is driven to rotate by the rotary drive device arranged on the frame 7, and the tool sample holder 10 for fixing the tool sample is connected to the lower end of the rotary shaft 11 through a movable interface, and then the tool sample holder is driven by the rotary drive device The tool sample on 10 rotates at high speed. The elevating shaft 8 drives up and down through the elevating driving device arranged on the frame 7, and the frame 7 is provided with an axle sleeve for the elevating shaft 8 to lift and slide, and the elevating shaft 8 and the axle sleeve are installed through spline fit, ensuring This prevents the lifting shaft 8 from rotating on the premise that the lifting shaft 8 can lift and slide in the axle sleeve....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com