A Numerical Control Programming Method of Conical Surface with Conical Surface with Conical Surface of Equal Width

A technology of conical surface and numerical control programming, applied in the field of numerical control programming, can solve the problems of long program, affecting the processing effect, cumbersome and long program, etc., and achieves the effect of good readability and modification, flexible and convenient modification and editing, and simple calculation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

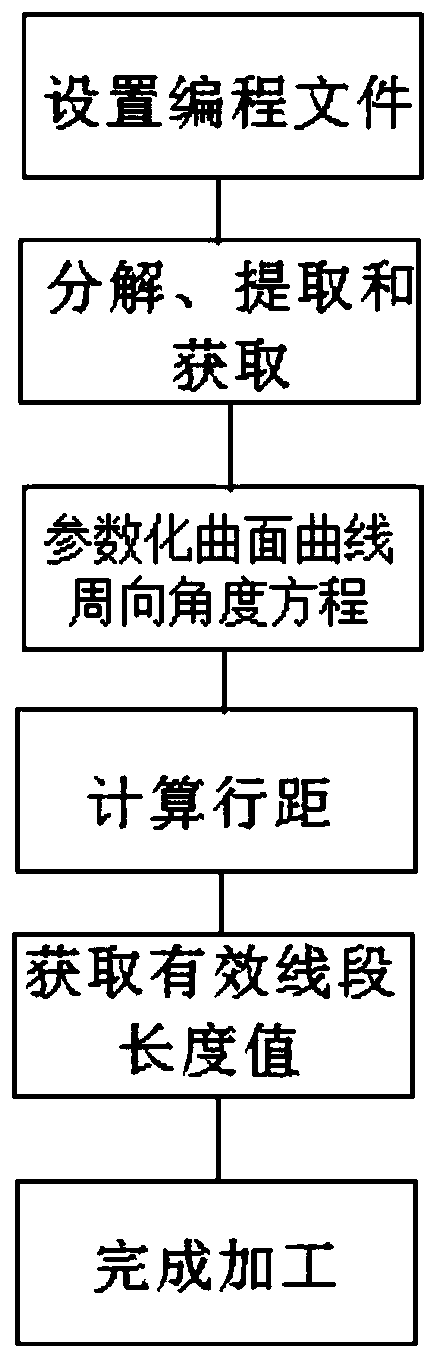

[0051] Such as figure 1 As shown, a NC programming method for conic surfaces with equal-width steps includes the following steps:

[0052] ①Setting the programming file: write the surface image, the function of the cutting method and the parameter line equation into the programming file, and the surface image is the surface image of three equal-width steps;

[0053] ②Decomposition, extraction and acquisition: Decompose the surface image, extract the surface equation, obtain the surface curve circumferential angle equation and the lateral step, and the lateral step is the distance between the tool and the tangent line of the circumferential angle of the surface curve;

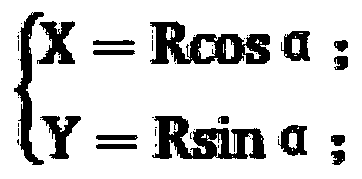

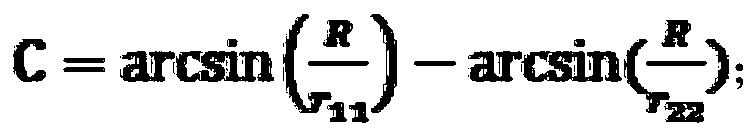

[0054] ③ Parametric surface curve circumferential angle equation: Use the parametric line equation and the surface curve circumferential angle equation to form an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com