Defect identification method for electrowetting display screen

A defect recognition and display technology, applied in the field of deep learning and image processing, can solve problems such as being easily affected by environmental factors such as light, cumbersome manual feature extraction, and low robustness, so as to improve training speed and recognition accuracy, and accelerate The effect of network convergence and strong robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

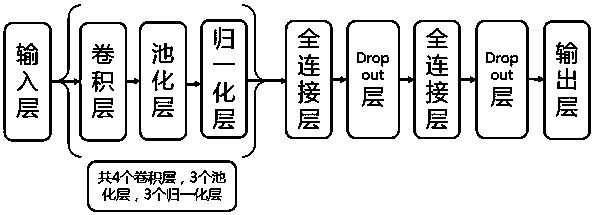

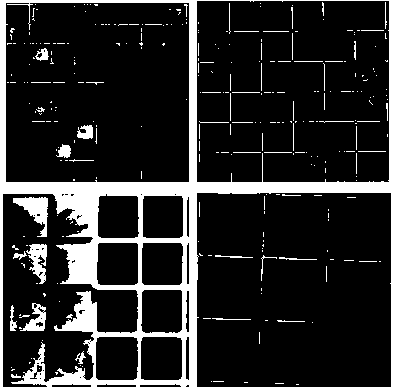

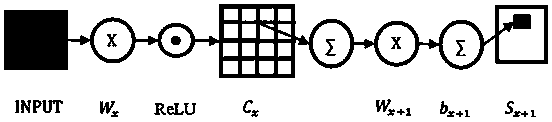

[0028] A method for identifying defects in an electrowetting display screen of the present invention is realized by using a convolutional neural network added to a batch normalization algorithm; the convolutional neural network includes four convolutional layers, three pooling layers, three Layer batch normalization layer, two layers of fully connected layers, two layers of Dropout layer and output layer; by adding batch normalization layer after the convolution layer, each layer of convolution layer has the same data distribution, improving the network The generalization ability of the network speeds up the convergence of the network, thereby improving the model training speed and recognition accuracy; the method specifically includes the following steps:

[0029] Step S1, normalize the input image to the uniform size required by the net...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com