Polishing pad conditioning method and chemical mechanical polishing method including same

A chemical-mechanical and polishing pad technology, used in grinding/polishing equipment, parts of grinding machine tools, abrasive surface conditioning devices, etc., to solve problems such as over-polishing of the edge of the polishing pad, decreased wafer flatness, and increased surface defects. , to achieve the effect of reducing thickness consumption, reducing the number of defects on the wafer surface, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

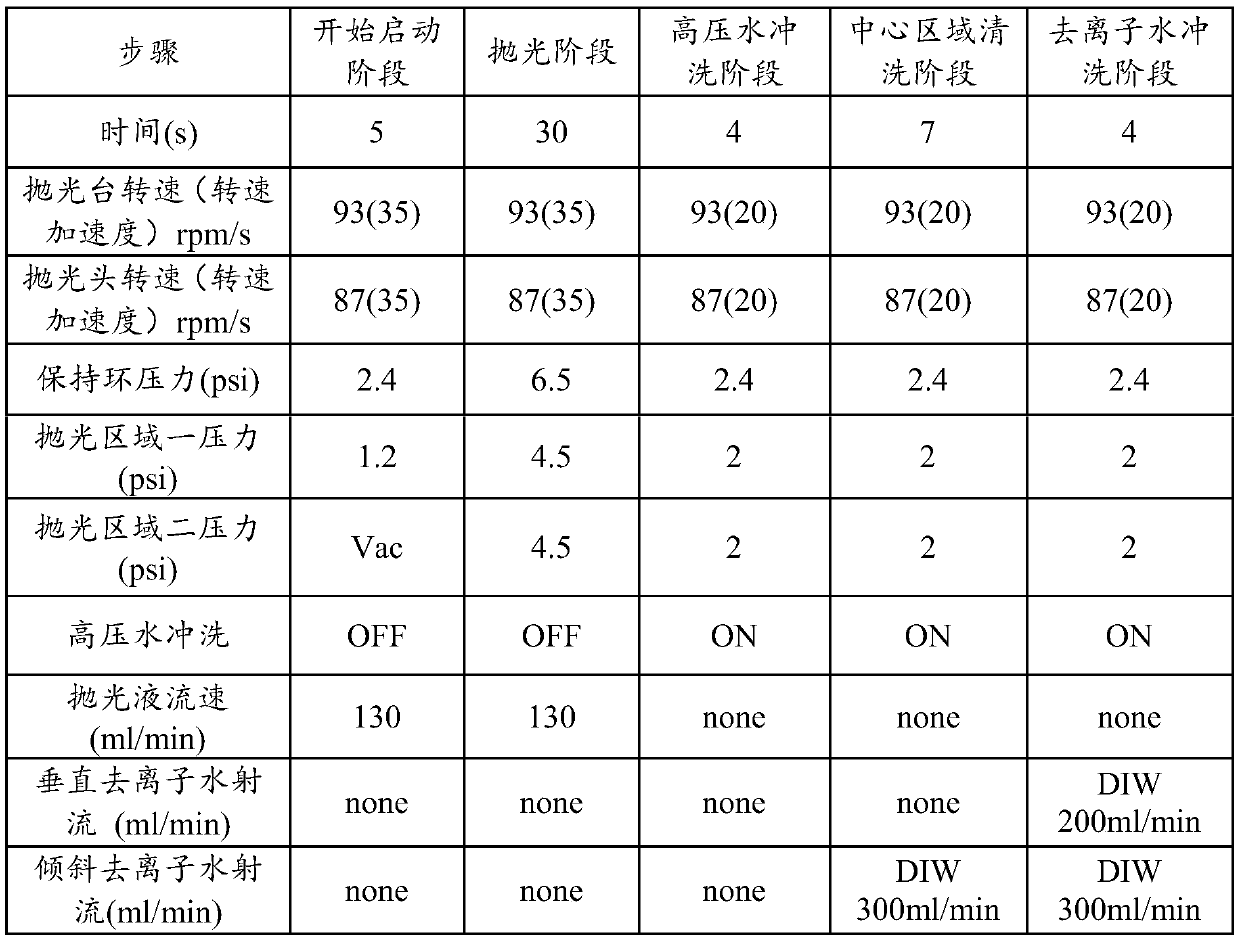

[0057] This embodiment is a chemical mechanical polishing method, wherein the polishing process and process parameters are listed in Table 1, and the trimming process parameters are listed in Table 2. The radius dimension of the polishing pad in this example is 254 mm and the size of the dresser is 108 mm.

[0058] Table 1 Polishing process and process parameters

[0059]

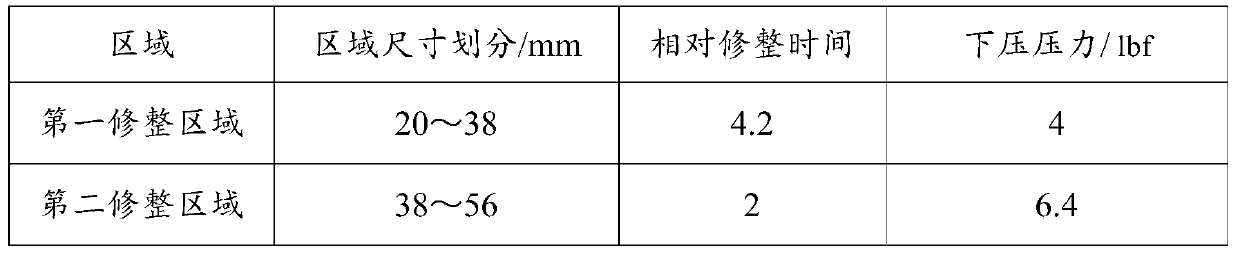

[0060] Table 2 trimming process parameters

[0061]

[0062]

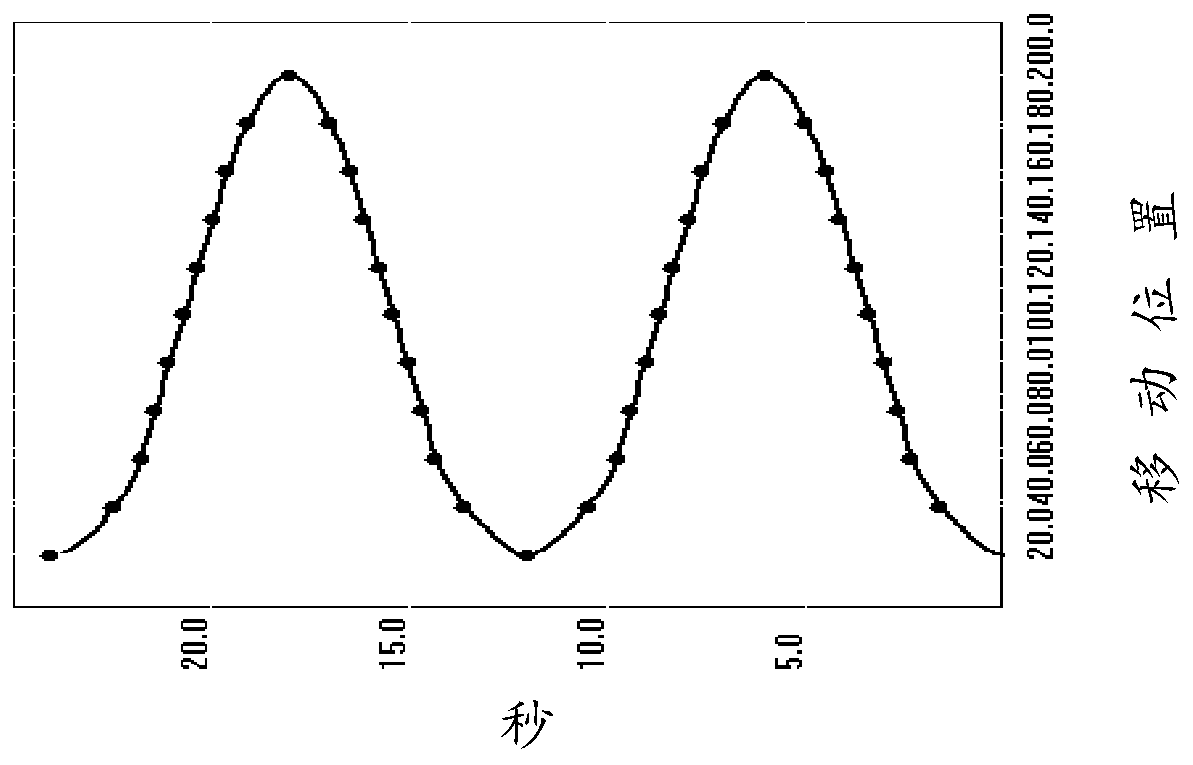

[0063] Note, in the division of the area size in Table 2, the starting point 20mm is the edge of the polishing pad. 20mm. The move roadmap of the trimmer is as follows figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com