Machining technology and method for lining of bathing surfing water pool

A processing technology and pool technology, applied in the direction of flat products, household appliances, other household appliances, etc., can solve the problems of lack of efficiency and simplification, increase of labor cost, increase of machine energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further elaborated below in conjunction with the drawings.

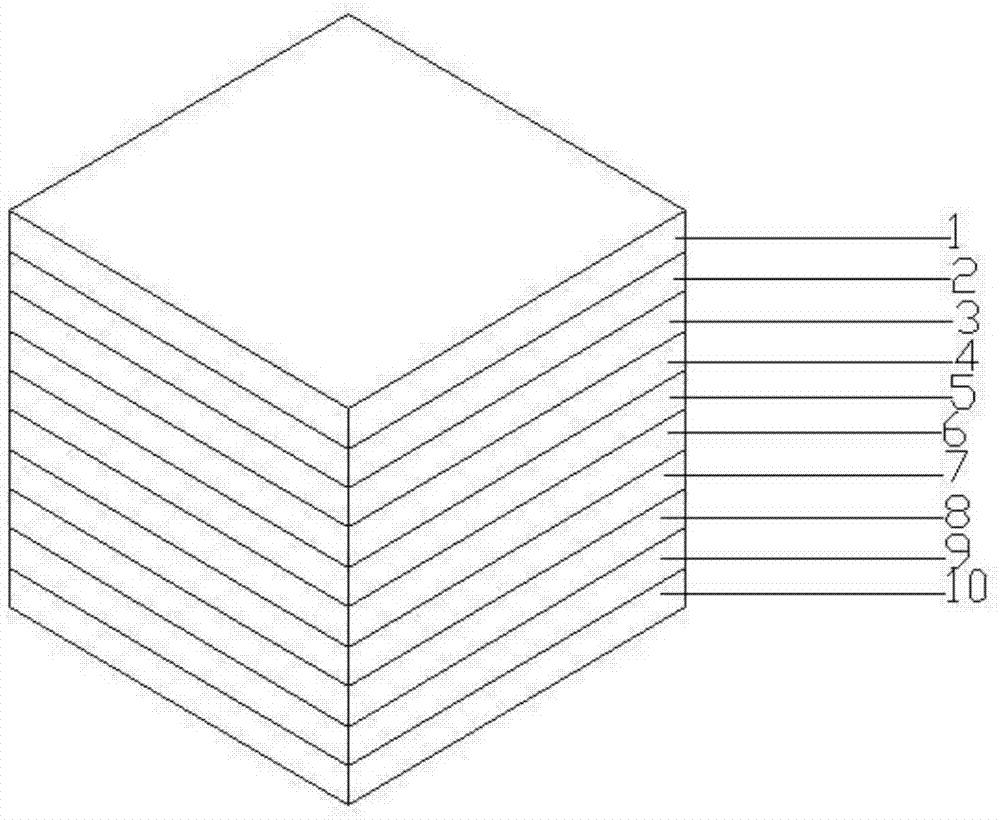

[0026] Such as figure 1 Shown, the present invention is a pool lining material.

[0027] Contains: -1 first plate layer, -2 second plate layer, -3 third plate layer, -4 fourth plate layer, -5 fifth plate layer, -6 sixth plate layer, -7 seventh plate layer layer, -8 the eighth sheet material layer, -9 the ninth sheet material layer, and -10 the last sheet material layer are combined by pressure bonding with EVA hot melt adhesive to form an integrated multi-layer processing profile.

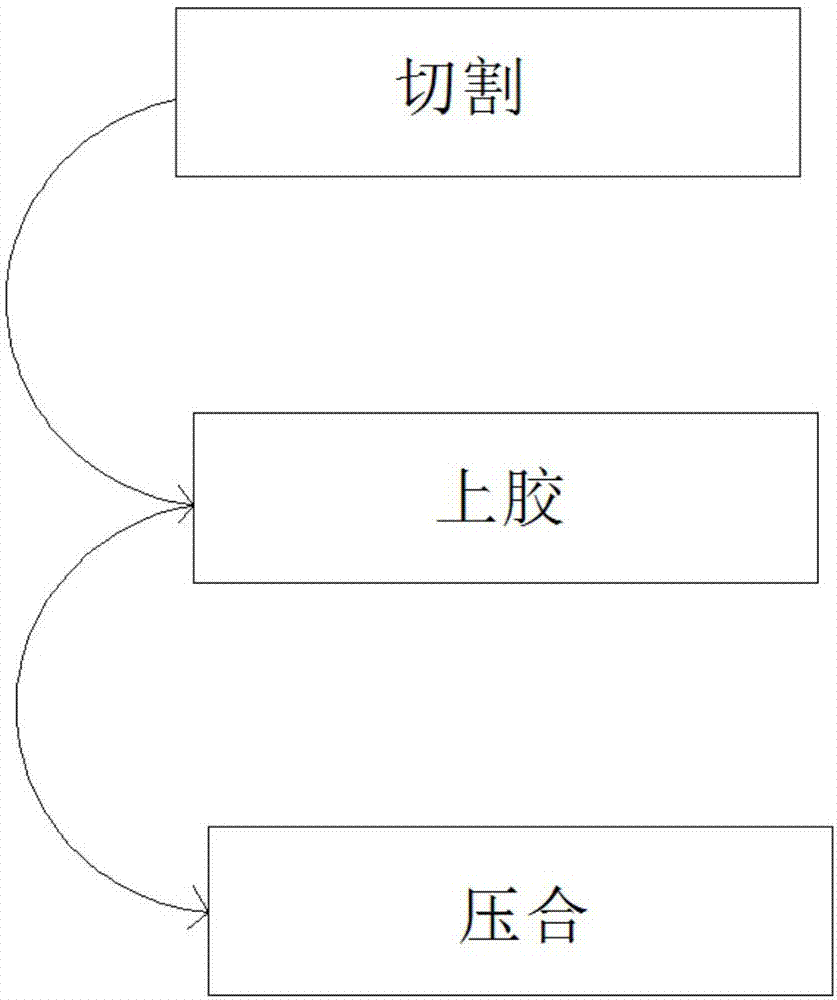

[0028] A bathing and surfing pool lining processing technology and method include cutting method, gluing method, and pressing method. The foaming light materials such as EPE, EPS, EVA, foamed plastic or sponge with strong support and heat preservation are selected. The selected materials are neatly arranged to the appropriate height of the vertical cutting machine, and the neatly arranged materials a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap