Vacuum pouring device for wind power blade molding

A technology for vacuum infusion and wind power blades, applied in the field of wind power blade forming, can solve the problems of easy mixing of air bubbles, excessive experience, complex process, etc., and achieve the effects of weak experience, simplified pouring process, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

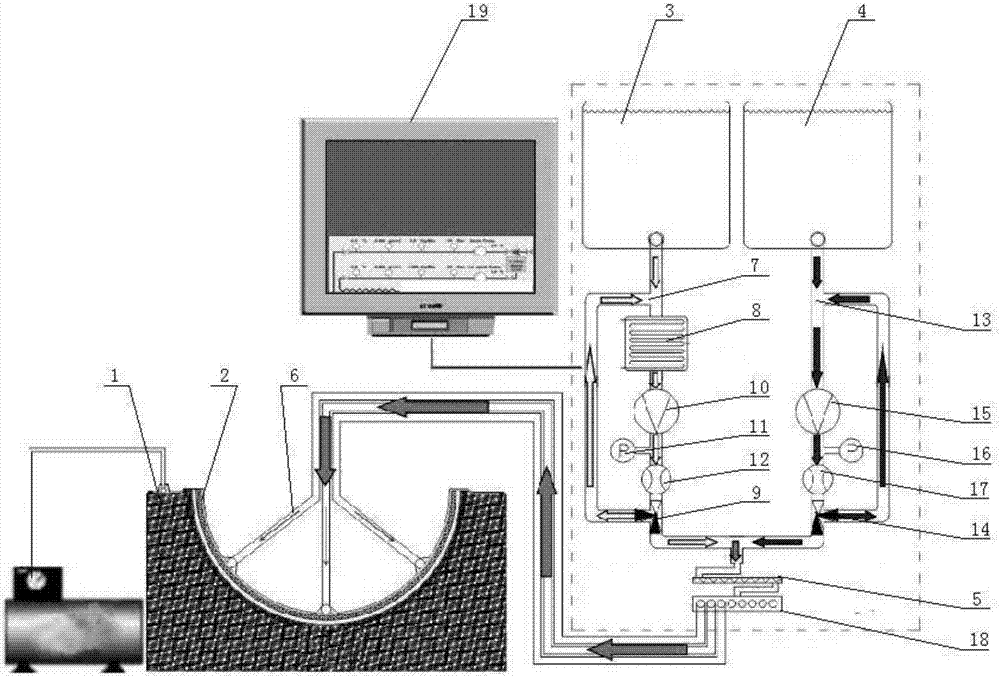

[0019] Such as figure 1 As shown, a vacuum infusion device for forming wind power blades includes a mold 1, a resin barrel 3, a curing agent barrel 4, a quantitative output circuit of the curing agent, and a preform 2 made of dry fiber reinforced material laid in it; the resin barrel 3 is sequentially connected to the resin quantitative circulation output circuit and the mixer 5; the curing agent barrel 4 is sequentially connected to the curing agent quantitative output circuit and the mixer 5; the mixer 5 is connected to multiple injection seats for preform 2 injection 6. Resin quantitative circulation output circuit and curing agent quantitative output circuit keep the mixing ratio of resin and curing agent stable.

[0020] In a preferred embodiment of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com