Cantilever single-beam suspension, lifting and operation device capable of passing through curved rail belt

The technology of a running device and cantilever is applied in the field of a single-girder suspension hoisting device with a cantilever that can pass through a curved rail, and can solve the problems of narrowing the working range, limiting the scope of application, and poor operability, so as to ensure stability and smoothness. flexibility, extended work area, and highly maneuverable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

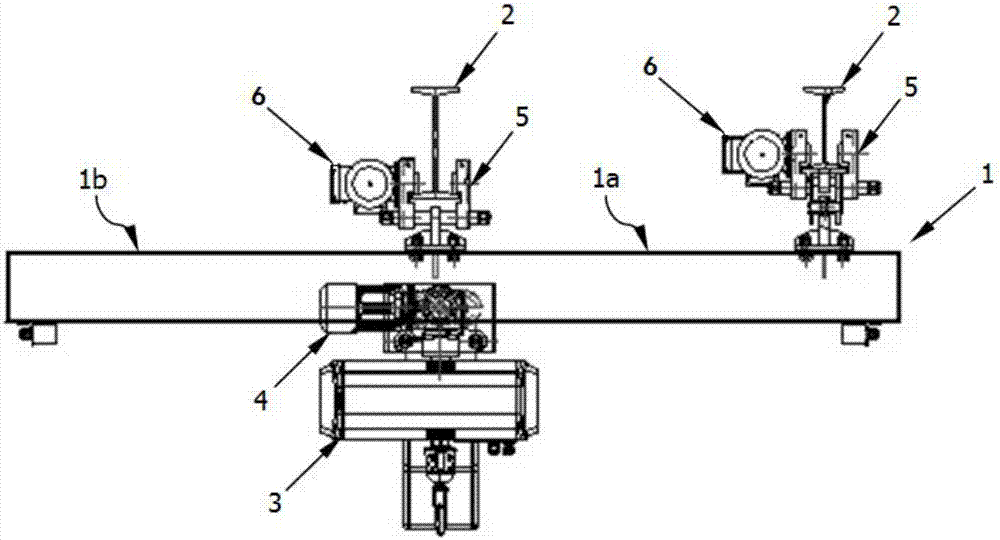

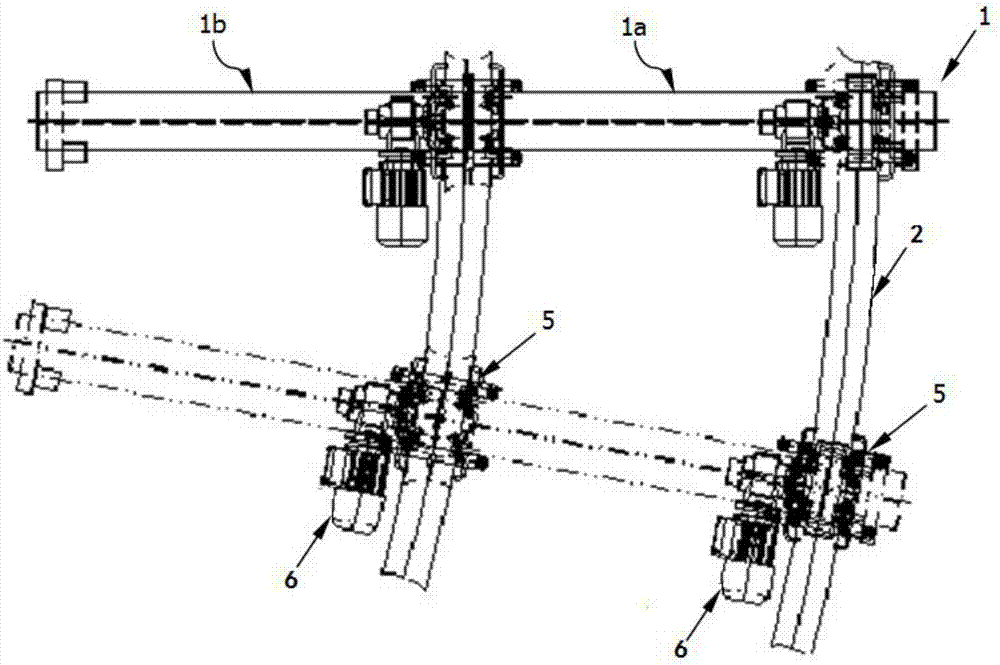

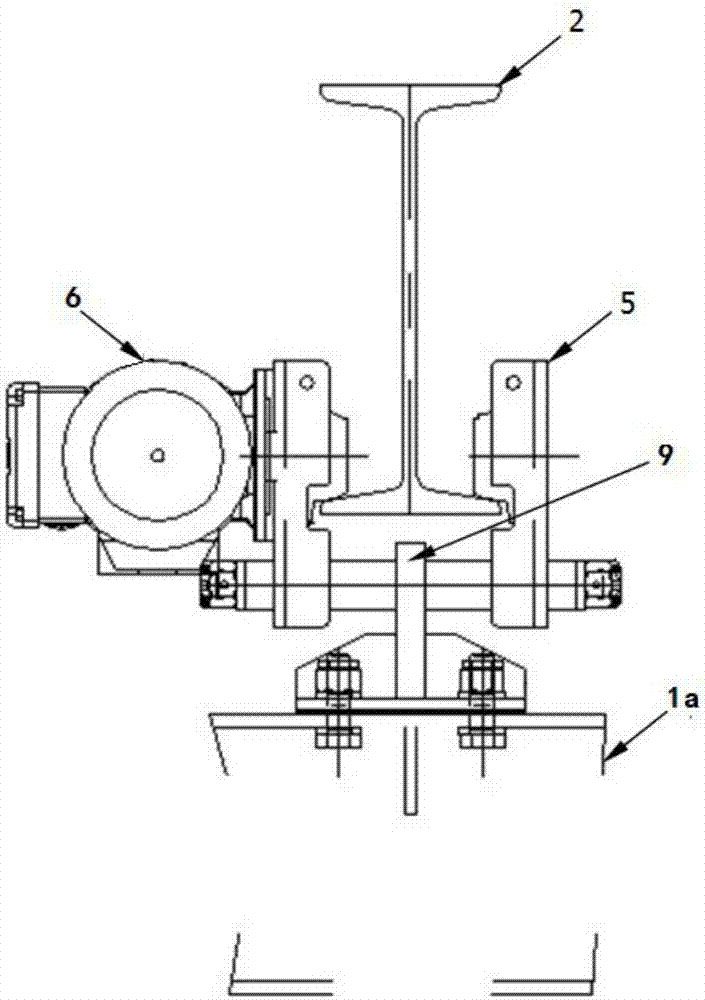

[0028] combine Figure 1 to Figure 6 Shown is the first specific implementation of a hoisting operation device with a cantilever single beam suspension on a curved rail belt of the present invention. First, the combination figure 1 , figure 2 As shown, the running device includes a main beam 1, two parallel track curved beams 2 arranged above the main beam 1 to guide its movement, and a hoist located below the main beam 1 3. The main beam 1 and the track curved beam 2 are H-shaped steel and I-shaped steel respectively. The main beam 1 is provided with a running trolley 4 that can move along its length direction. The running trolley 4 includes a vehicle frame and equipment The motor on the frame is connected and fixed on the running trolley 4 with the lifting hoist 3 .

[0029] In this embodiment, the main beam 1 includes a main beam body 1a and a main beam cantilever 1b provided on one end of the main beam body 1a and extending along its length direction, and the main beam ...

Embodiment 2

[0031] Embodiment 2: In this embodiment, combining Figure 7 As shown, the difference from Embodiment 1 is that the main girder 1 includes a main girder body 1a and a main girder cantilever 1b extending along its length direction on the left and right ends of the main girder body 1a. Compared with the existing technology, the working area is greatly expanded. In order to ensure that the whole device has a certain stability when the lifting hoist 3 and the running trolley 4 travel to the main beam cantilever 1b on both sides, the trolley 5 suspended on both sides must be equipped with anti-roller sets at the same time. 7 and the drive motor 6, and a rotating member is also provided between the suspension trolley 5 and the connecting plate 9 on both sides to realize the hinge between the suspension trolley 5 and the main beam 1, because the two suspension trolleys 5 are connected to the main beam 1 Hinged, so that the main beam 1 can swing relative to the track curved beam 2 dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com