Staggered type magnetic fluid sealing device

A magnetic fluid sealing and staggered technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as difficult to achieve vacuum sealing, inconspicuous effect, and failure to reach high speed, etc., to improve pressure resistance and sealing performance, expanding the safe working range, increasing the effect of magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

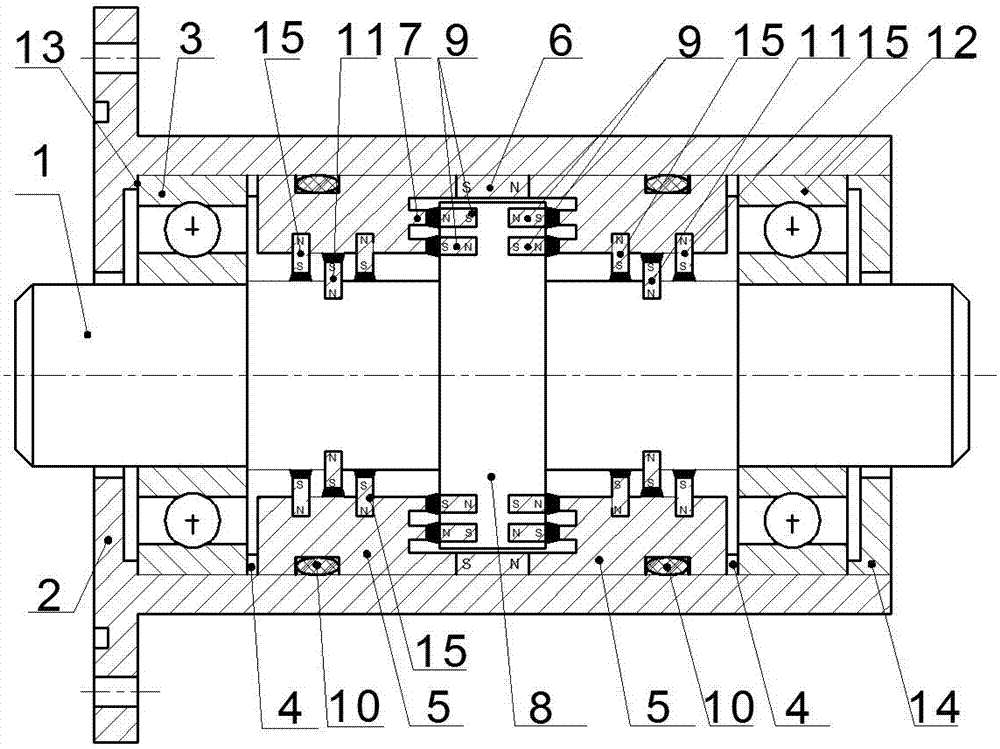

[0034] Such as figure 1 As shown, a staggered magnetic fluid sealing device includes a hollow housing 2, a rotating shaft 1 arranged in the inner cavity of the housing 2, and a radial direction between the outer surface of the rotating shaft 1 and the inner wall of the housing 2 is provided. The axially magnetized first permanent magnet 6 is provided with pole shoes 5 on both sides of the first permanent magnet 6 .

[0035] At least one third groove is formed in the upper direction of the rotating shaft 1 , and a third permanent magnet 11 is arranged in each third groove.

[0036] At least one fourth groove is provided on the inner surface of each pole piece 5 in the circumferential direction, and a fourth permanent magnet 15 is arranged in each fourth groove.

[0037] The third permanent magnet 11 and the fourth permanent magnet 15 are radially magnetized split permanent magnet rings with opposite polarities.

[0038] The outer circular surface of the third permanent magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com