Monitor connecting support moving mechanism

A technology for connecting brackets and moving mechanisms, which is applied in the direction of machines/supports, supporting machines, mechanical equipment, etc., can solve problems such as unsuitable for monitor adjustment, impossible monitoring, etc., to expand the monitoring angle of view, reduce restrictions, and have strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0014] The present invention will be described in detail below with reference to the accompanying drawings and examples.

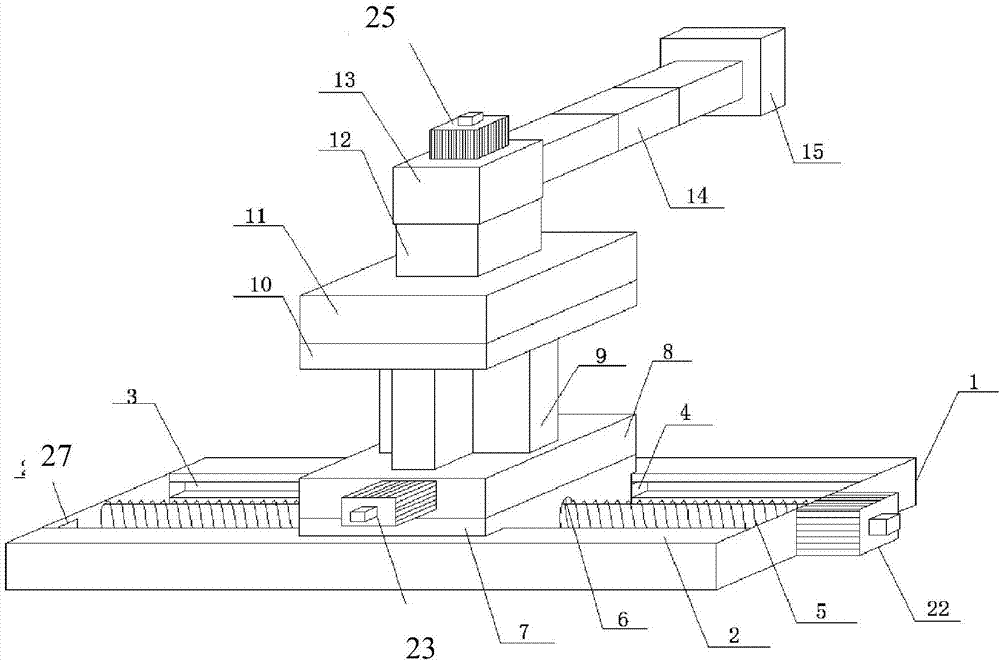

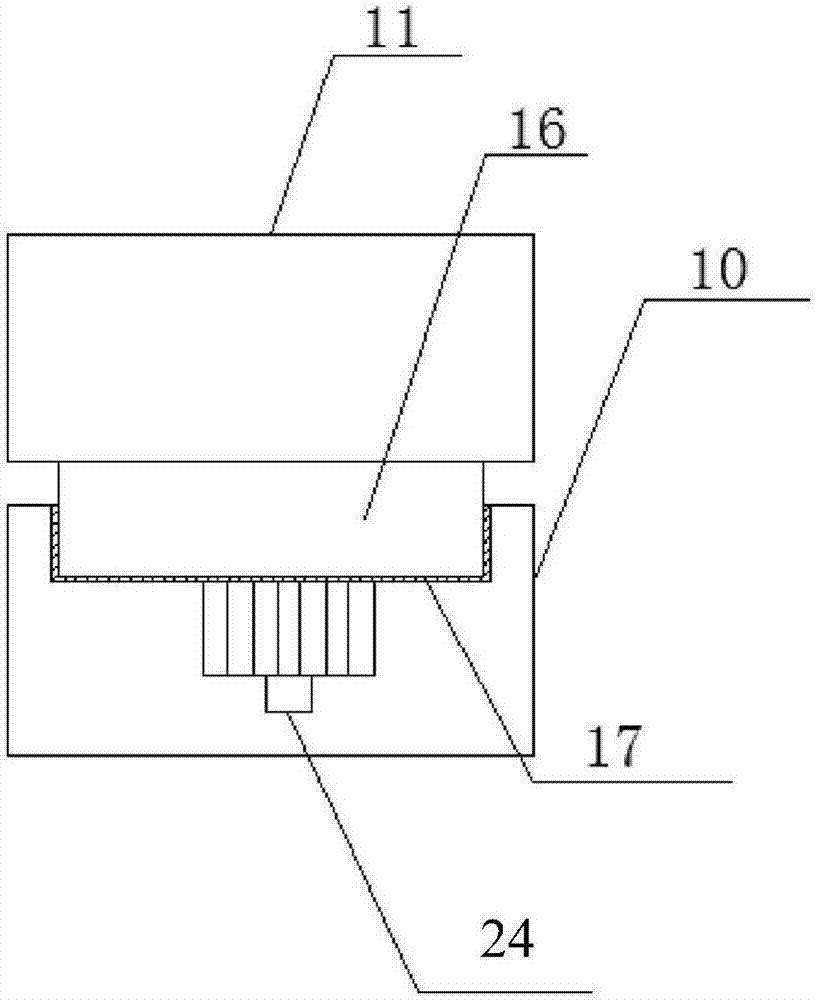

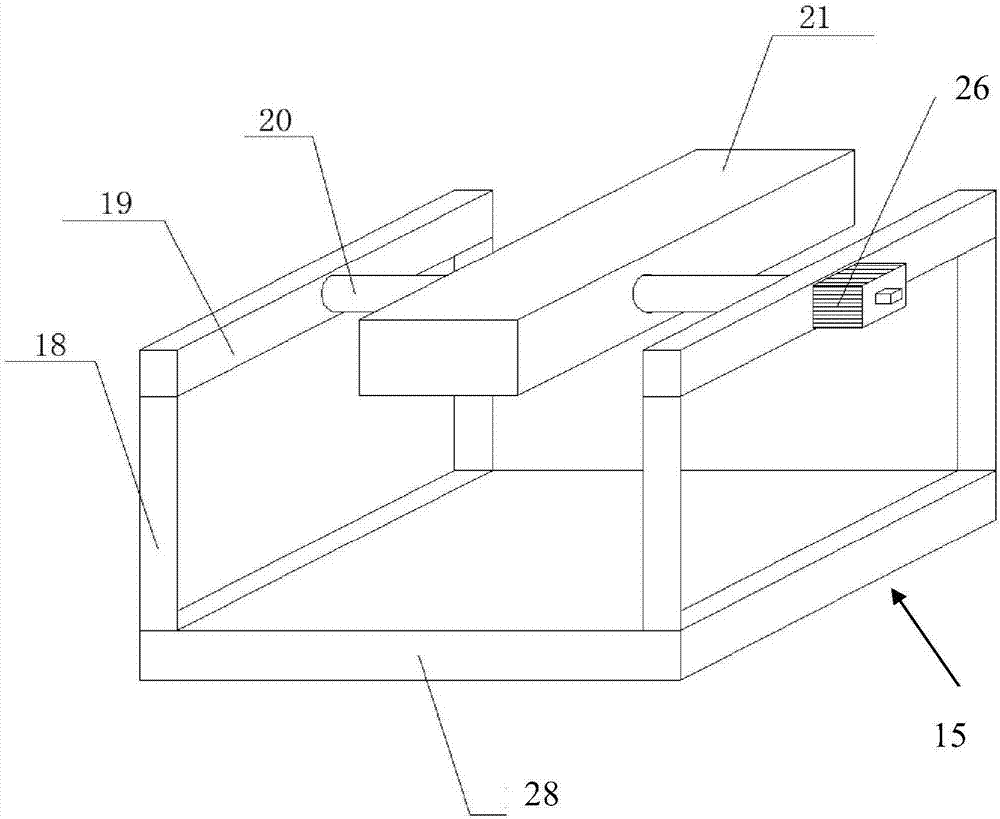

[0015] Such as figure 1 , figure 2 and image 3 As shown, the moving mechanism of the monitor connection bracket provided by the present invention includes a base 1, a lead screw 5, a first connecting platform 7, a first working platform 8, a telescopic column 9, a second connecting platform 10, a second working platform 11, a support Rod 12, third workbench 13, telescopic rod 14, bracket 15, first to fifth motors 23-26; wherein, the base 1 is a rectangular frame structure arranged horizontally, on the opposite sides of the two long sides 2 A chute 3 is respectively recessed along the length direction; the lead screw 5 is arranged inside the base 1 in a rotating manner, and is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com