A power battery insertion mechanism

A power battery and plug-in technology, applied in circuits, electrical components, circuit/collector parts, etc., can solve the problems of low efficiency, numerous sockets and laborious plug-in efficiency, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

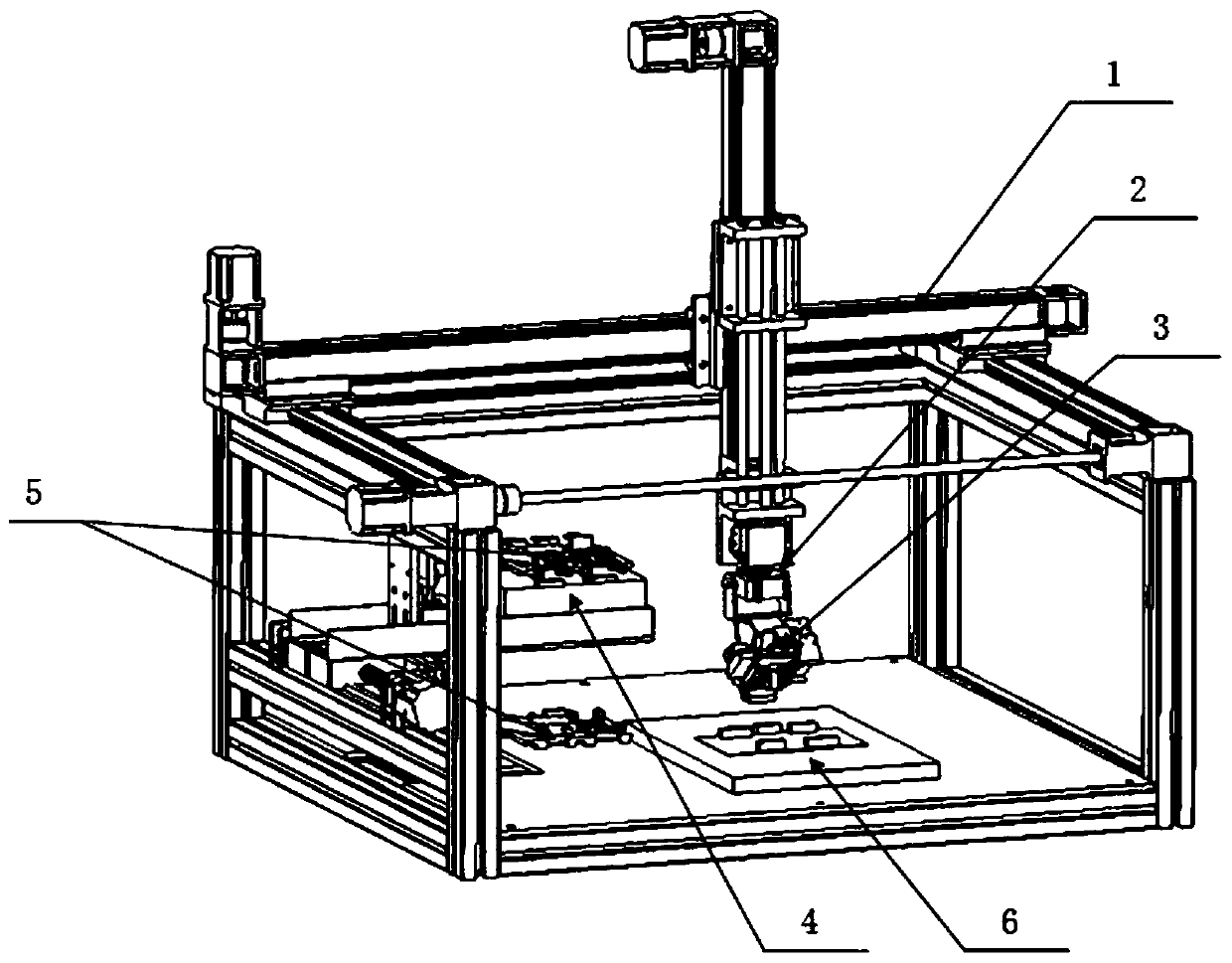

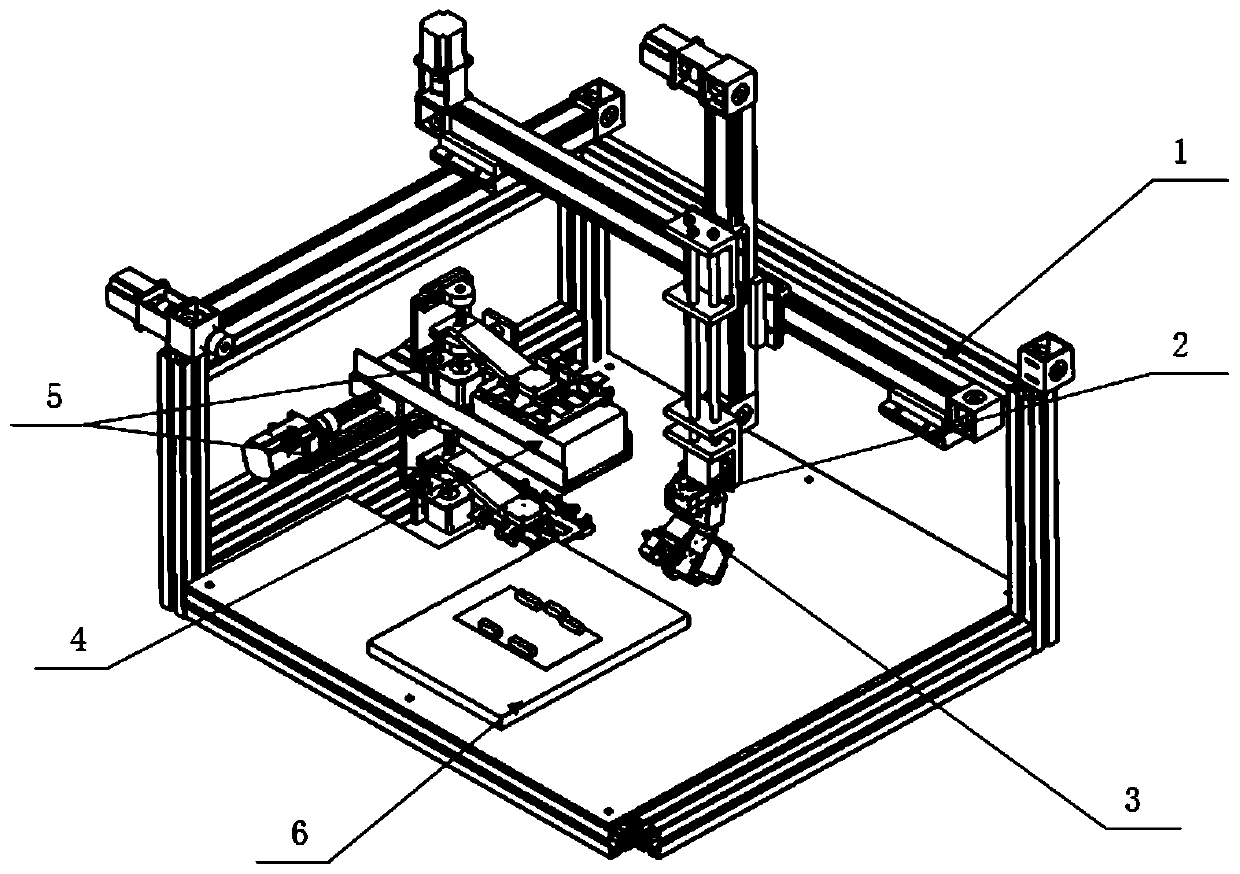

[0029] see figure 1 as well as figure 2 , a power battery wire insertion mechanism, including a control terminal (not shown in the figure), a mobile platform 1, and a wire-strapping device 3 installed on the mobile terminal 2 of the mobile platform 1 and electrically connected to the control terminal.

[0030] With the above structure, the control terminal controls the threading device 3 to pick up the wire harness, and performs threading operations on both ends of the wire harness to fix and clamp the plug of the wire harness; the threading device 3 is installed on the mobile terminal 2 of the mobile platform 1, and the control terminal controls The mobile terminal 2 and the thread-strapping device 3 are used to complete the plug-in operation with the socket of the power battery 4, and an automatic device is used instead of manpower to realize the plug-in of the wire harness, which improves work efficiency.

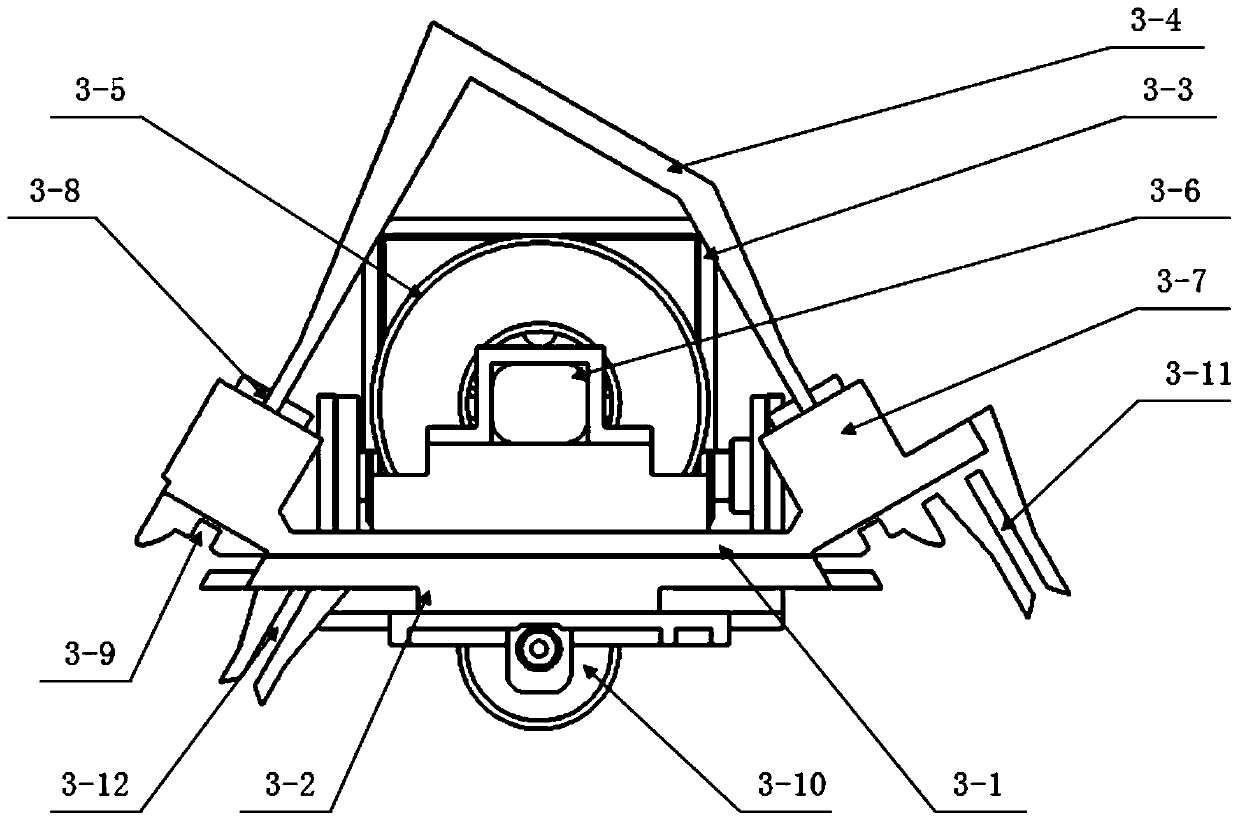

[0031] Further, see image 3 as well as Figure 4 , in a specif...

Embodiment 2

[0037] see Figure 5 , in order to ensure that the wiring harness plug and the battery jack can be aligned when the wiring harness is plugged in, to improve the accuracy of plugging, and to prevent damage to the plug and the jack due to position deviation during the plugging process, this embodiment is in the embodiment On the basis of 1, a further improvement is made. The power battery wire insertion mechanism in this embodiment also includes a positioning plate 5 for auxiliary wire insertion. The horizontal guide piece 5-1 corresponding to the horizontal insertion hole of the battery is also provided with a vertical guide groove 5-2 corresponding to the vertical insertion hole of the battery.

[0038] Further, the first end of the upper splint 3-1 is provided with a first guide groove 3-11, and the second end of the lower splint 3-2 is provided with a second guide groove 3-12; When inserting wires, the horizontal guide piece 5-1 snaps into the first guide groove 3-11 or the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com