Material washing device and cooking utensil

A technology for cleaning devices and cooking utensils, which is applied to cooking utensils, household utensils, kitchen utensils, etc., can solve the problems of inability to automatically wash rice and rice structure, affect the user experience of products, and inconvenience in complex use, achieving good cleaning effect and avoiding nutrients. churn, the effect of promoting interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

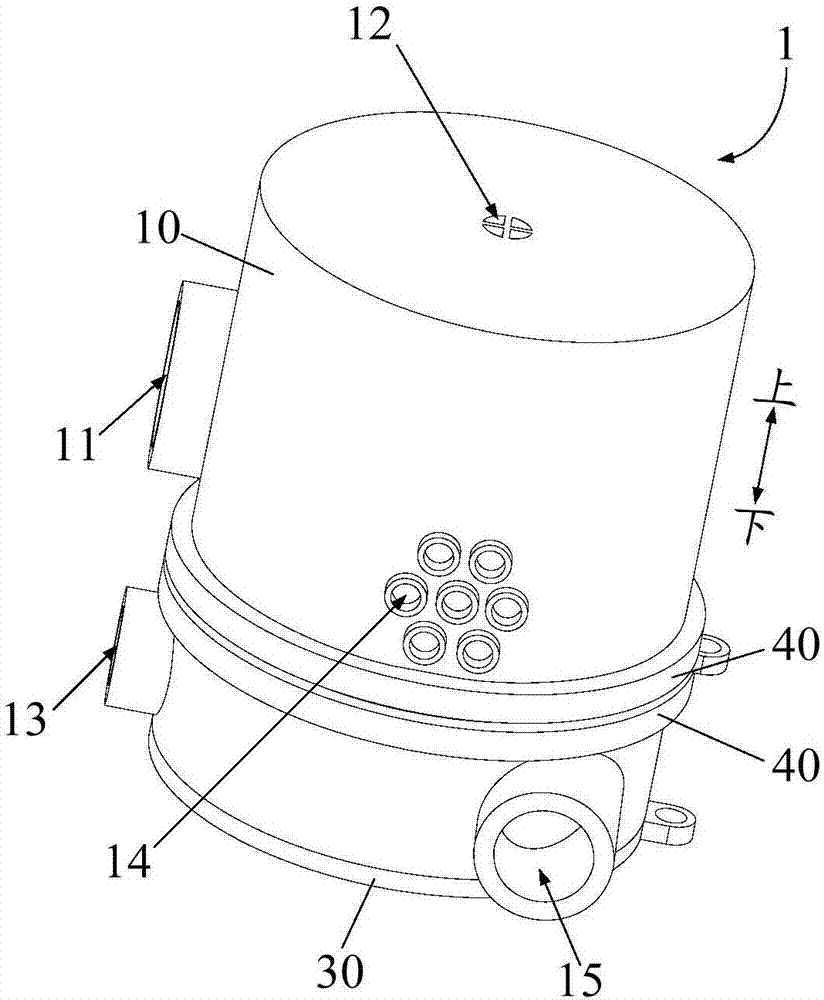

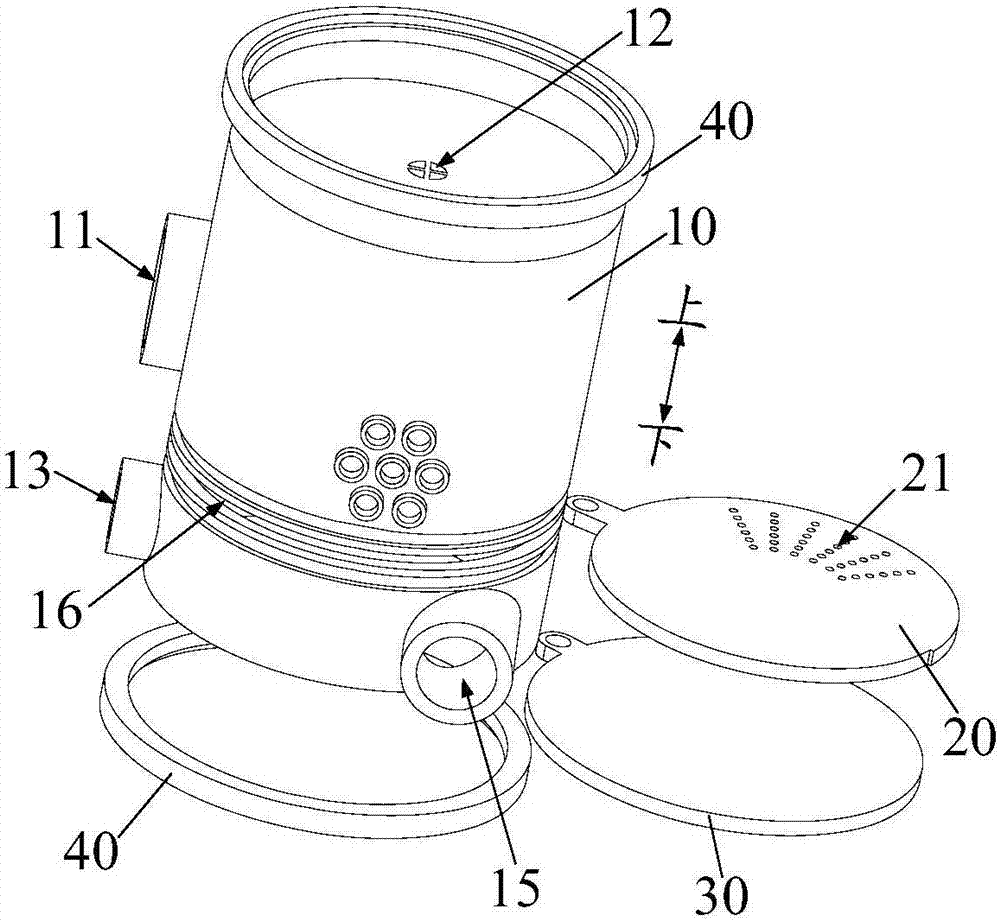

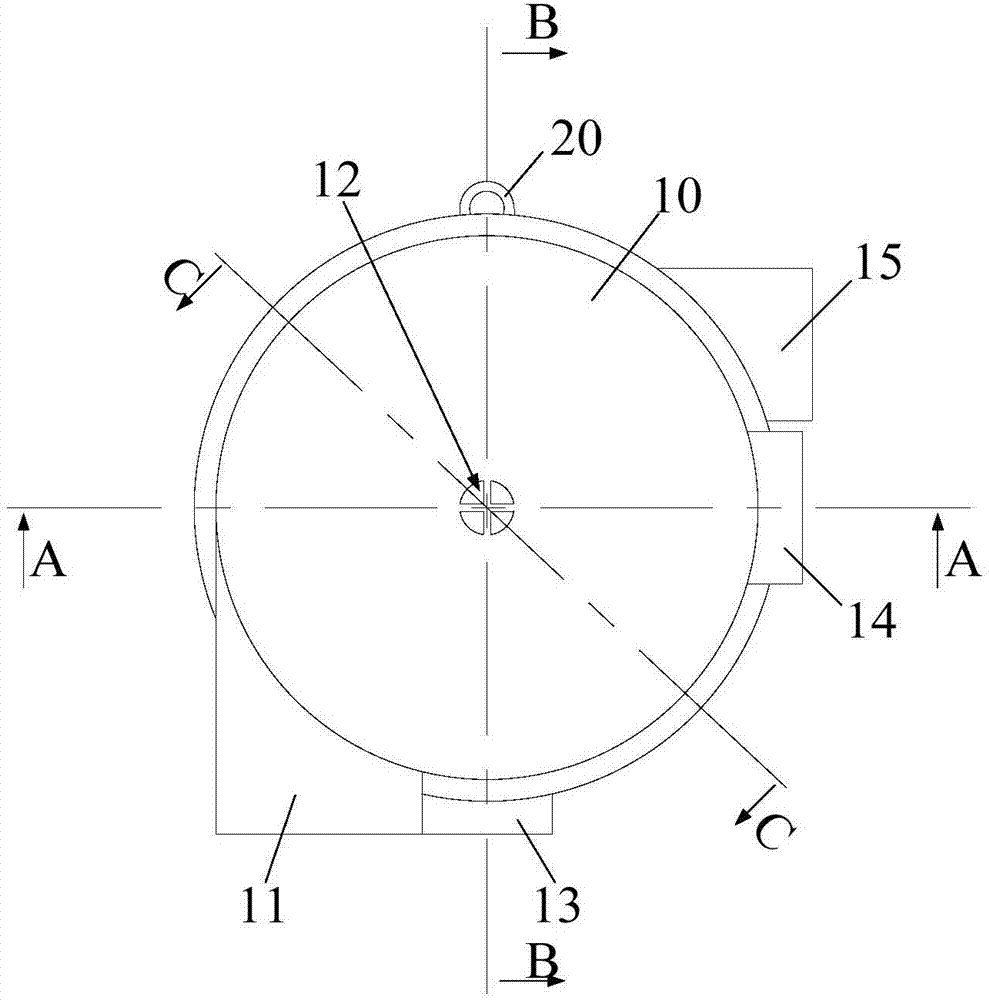

[0061] Such as Figure 1 to Figure 6 As shown, the air supply port and the feed port 11 are multiplexed.

[0062] Such as figure 1 , figure 2 , image 3 , Figure 5 and Figure 6 As shown, the cleaning chamber 10 is also provided with an air inlet 13 , and the air inlet 13 is used to deliver compensation airflow into the cleaning chamber 10 to compensate the airflow loss in the cleaning chamber 10 .

[0063] Further, as figure 1 and Figure 6 As shown, the air inlet 13 is located below the feed port 11, and a partition 20 is also provided in the cleaning chamber 10, and the partition 20 is located between the air inlet 13 and the feed port 11, and will clean the inside of the chamber 10 The space is divided into a first chamber 17 and a second chamber 18 below the first chamber 17, such as Figure 4 , Figure 5 and Figure 6 shown; wherein, the partition 20 is provided with a vent hole 21, so that the compensation airflow input by the air inlet 13 can enter the firs...

Embodiment 2

[0087] Embodiment 2 (not shown in the figure)

[0088] The difference from Embodiment 1 is that: the partition plate 20 is reversibly arranged in the cleaning chamber 10 , and the communication or separation between the first chamber 17 and the second chamber 18 is realized by reversing.

[0089] The working principle of this embodiment is basically the same as that of Embodiment 1, and can achieve the object of the present invention, so it will not be repeated here.

Embodiment 3

[0090] Embodiment three (not shown in the figure)

[0091] The difference from Embodiment 1 is that the partition plate 20 is slidably inserted into the cleaning chamber 10 , and the communication or isolation between the first chamber 17 and the second chamber 18 is realized by pulling out or inserting.

[0092] The working principle of this embodiment is basically the same as that of Embodiment 1, and can achieve the object of the present invention, so it will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com