Reverse roller coating patching machine for sheepskin clothing leather

A garment leather and roller coating technology, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve problems such as difficulty in skin passing, leather folding, etc., and achieve the effect of improving work efficiency and realizing automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

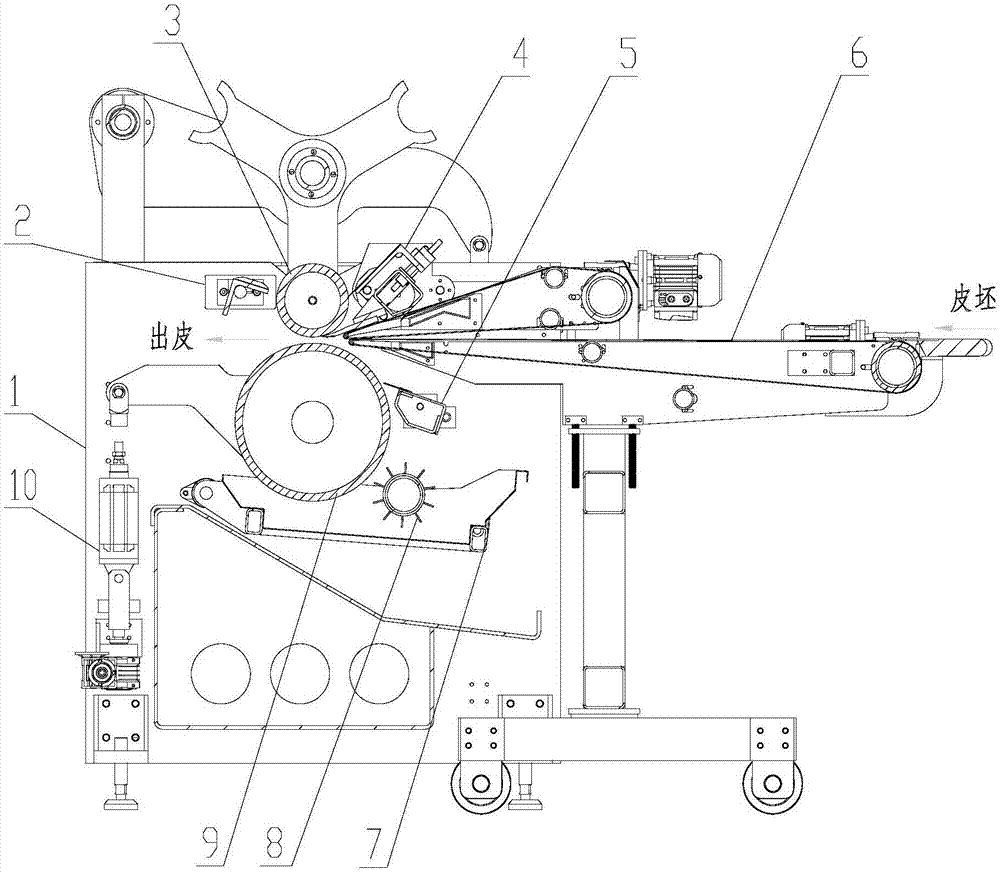

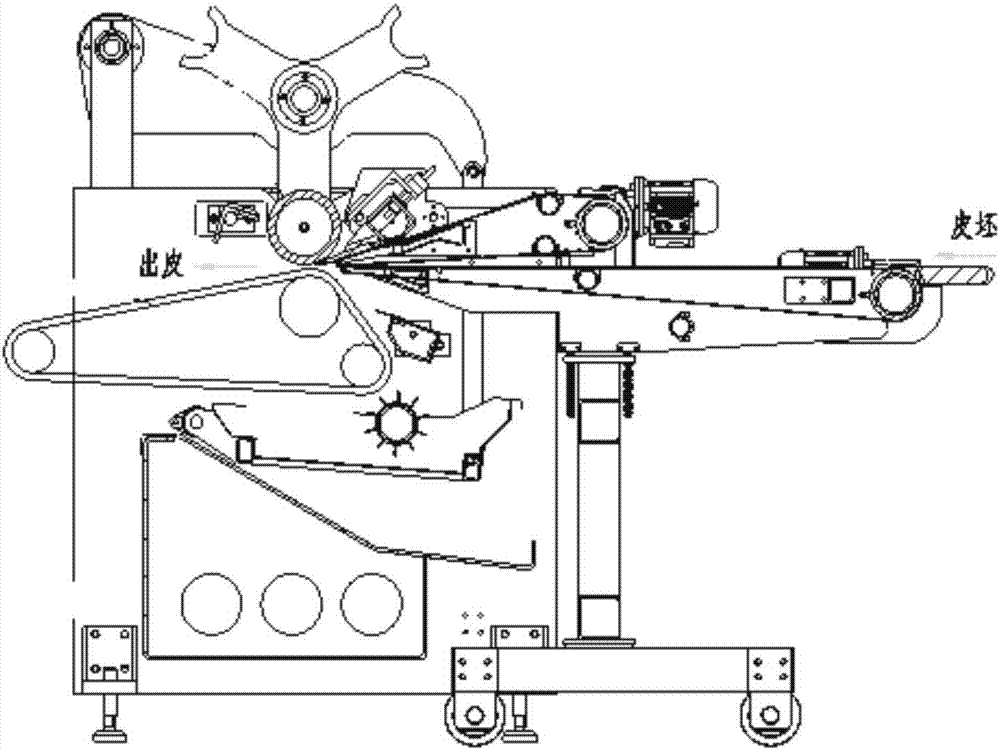

[0057] Such as figure 1The sheepskin garment leather roller coating repairing machine shown is mainly composed of a frame 1, a scraper part 2, a finishing roller 3, a pressing knife part 4, a wiper part 5, a skin feeding device 6, a roller changing part 7, and a water tank part 8 , rubber roller 9, rubber roller adjustment device 10 and other components.

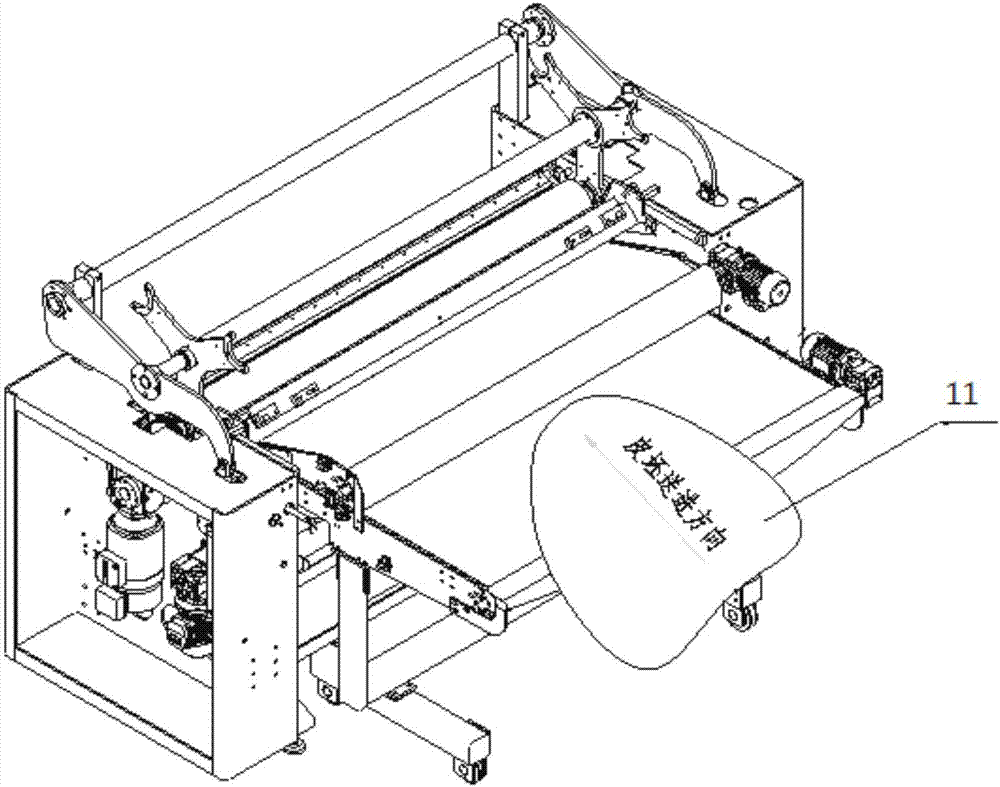

[0058] Such as figure 1 As shown, the leather feeding device 6 is a unit that can advance and retreat independently, and is composed of two layers of conveyor belts. As it is fed forward, the upper conveyor belt ensures that the sheepskin is kept flat during the forward process. Such as figure 2 As shown, the sheepskin 11 is placed on the conveyer belt in an orientation that is conducive to the sheepskin passing through the roller coating area. When putting the skin, it is required that the prominent structure of the sheepskin stretches forward.

[0059] In a general roller coating machine, the leather enters the roller...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com