High-precision locating pin knocking-in mechanism

A positioning pin, high-precision technology, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems of difficult installation, complex workpiece shape, inconvenient manual operation, etc., and achieve the effect of inconvenient installation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

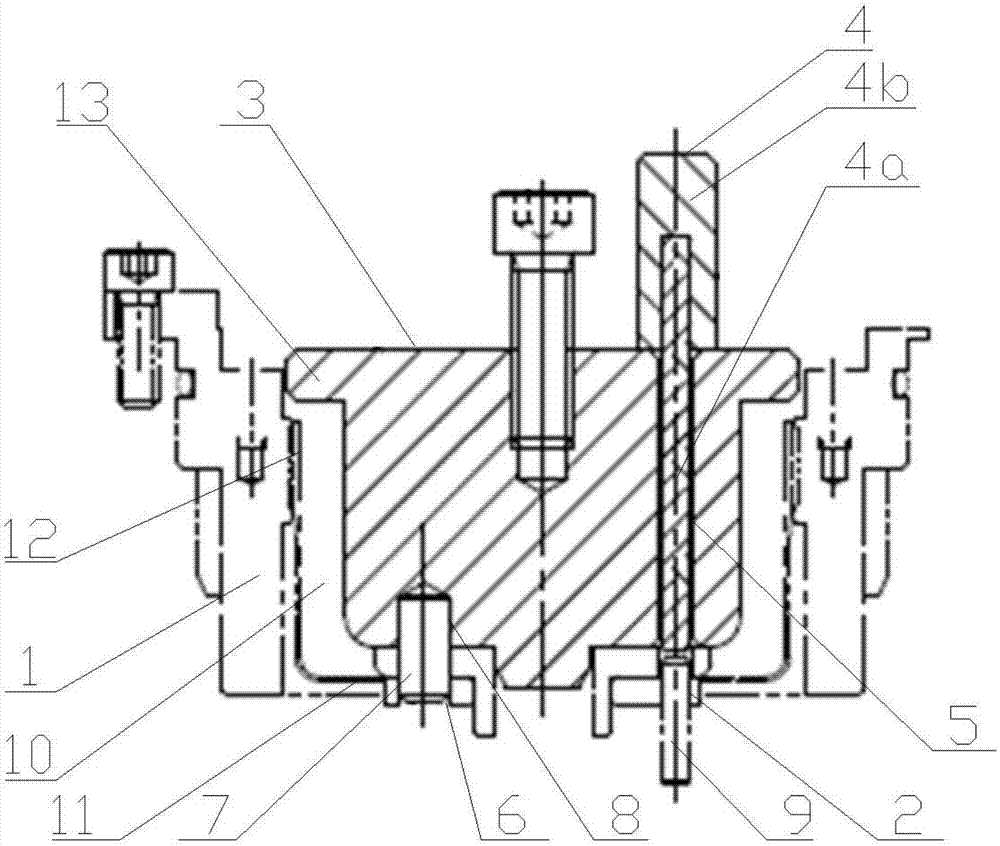

[0015] Such as figure 1 As shown, it corresponds to a high-precision positioning pin knocking mechanism of a preferred embodiment of the present invention, which is used to install the positioning pin 9 into the workpiece 1 . The workpiece 1 is provided with a concave portion 10 , and the concave portion 10 is surrounded by a bottom surface 11 and a side wall 12 . On the bottom surface 11, a plurality of pin holes 2 (only one pin hole 2 is acceptable) are provided with a plurality of positioning pins 9 to be installed.

[0016] The high-precision positioning pin knocking mechanism includes a body 3 , a punch 4 and a positioning piece 7 which are independent of each other. The main body 3 is provided with a positioning portion 13 matching with the side wall 12 , and the positioning member 7 is disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com