Method for evaluating inclusion types of steel and induced pitting trend thereof

A technology of inclusions and species, applied in the direction of measuring devices, instruments, scanning probe microscopy, etc., can solve the problems of inability to distinguish the difference between induced pitting corrosion and quantitative evaluation of localized corrosion such as pitting corrosion induced by inclusion types

Inactive Publication Date: 2018-04-27

UNIV OF SCI & TECH BEIJING

View PDF4 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The pitting potential of different steel types in different environments may have a small difference. In addition, with the change of the environment, the pitting potential will change significantly. Therefore, the experimental results obtained by this method cannot quantitatively evaluate the inclusions. Types and their probability of inducing localized corrosion such as pitting

Due to the large number of inclusions in the steel, the types are often not single. This method is a macroscopic measurement. The measured pitting potential of all inclusions in the steel cannot distinguish the difference between the pitting corrosion induced by different types of inclusions.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

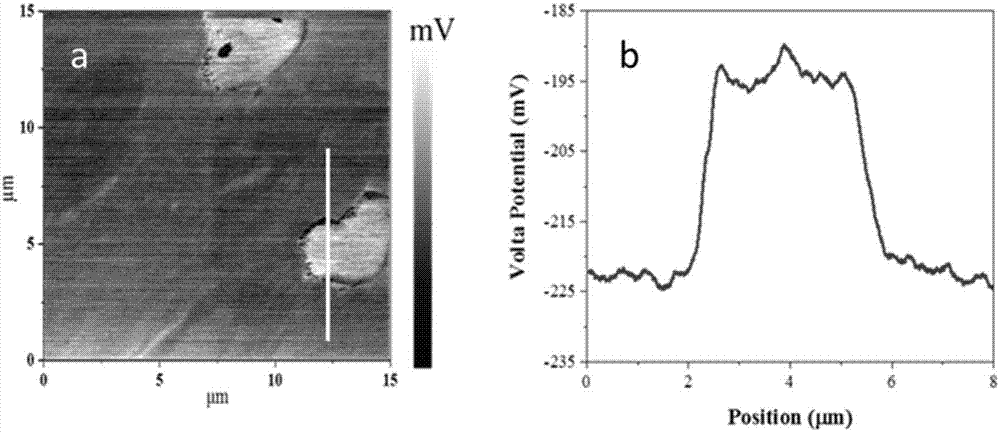

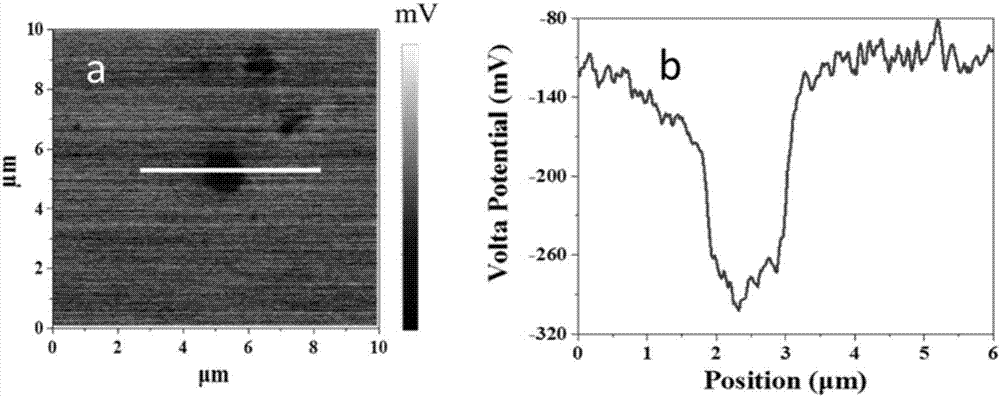

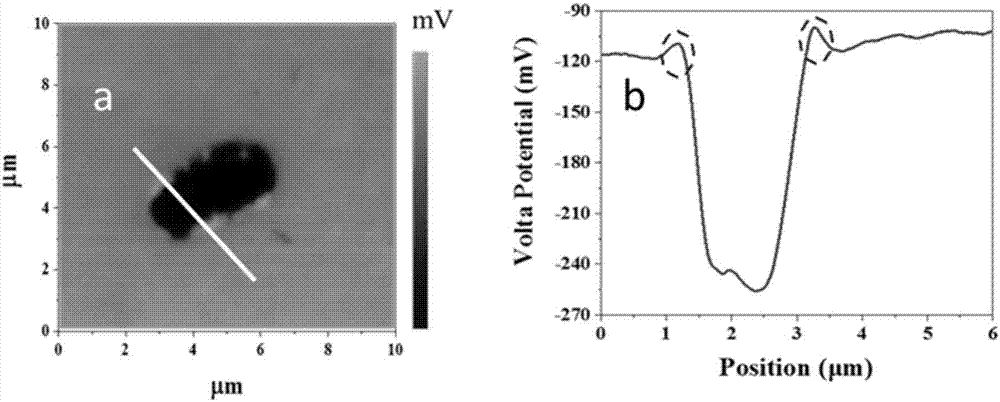

[0030] Cut samples of 10*10*5mm to be tested from aluminum deoxidized Q460 steel (1# steel) and rare earth modified aluminum deoxidized Q460 steel (2# steel). Place the samples on the experimental platform of the SKPFM system, and use the probe to scan the inclusion area. The probe has a frequency of 65 kHz and a scanning frequency of 0.1 Hz.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a method for evaluating inclusion types of the steel and an induced pitting trend thereof and belongs to the corrosion evaluation field. The inclusions of the steel are an important factor for induced pitting and other local corrosion. According to volt potential distribution of the inclusions of the steel, the types of the inclusions are discriminated, and the probabilityof induced pitting of the inclusions is evaluated. According to the method, the atomic force microprobe technology is employed for test, the types of the inclusions and the induced pitting difficultydegree can be clearly determined, moreover, the induced pitting phenomenon of the inclusions of the steel is further quantified, relative induced pitting probabilities of different inclusions can beacquired, corrosion resistance of the steel can be evaluated through utilizing the relative probabilities, and the evaluation result is of great importance for development of novel steel products, engineering structure design material selection and steel corrosion life evaluation .

Description

Technical field [0001] The invention belongs to the field of corrosion assessment, and particularly provides a method for identifying inclusion species and the probability of inducing pitting corrosion. Background technique [0002] Pitting corrosion is the most common type of corrosion in steel. Pitting corrosion can initiate and develop in a small area, accompanied by a high local corrosion rate, which will lead to structural failure and endanger the service safety and life of steel. Due to the hidden, random and sudden nature of local corrosion such as pitting, it is difficult to detect and evaluate the probability of pitting with conventional macro-electrochemical techniques. Inclusions in steel are an important factor in inducing local corrosion such as pitting corrosion. Different types of inclusions have different probabilities for inducing pitting corrosion. Therefore, a method for detecting the types of inclusions in steel and the probability of inducing pitting corrosi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01Q60/30

CPCG01Q60/30

Inventor 李晓刚刘超程学群刘智勇张达威

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com