Solid-sealed pole and dual power switch

A technology of solid-sealed poles and poles, which is applied in the direction of electric switches, high-voltage/high-current switches, circuits, etc., can solve the problems of inconvenient installation and large volume, reduce mechanism settings, control the overall volume, and reduce the number of settings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

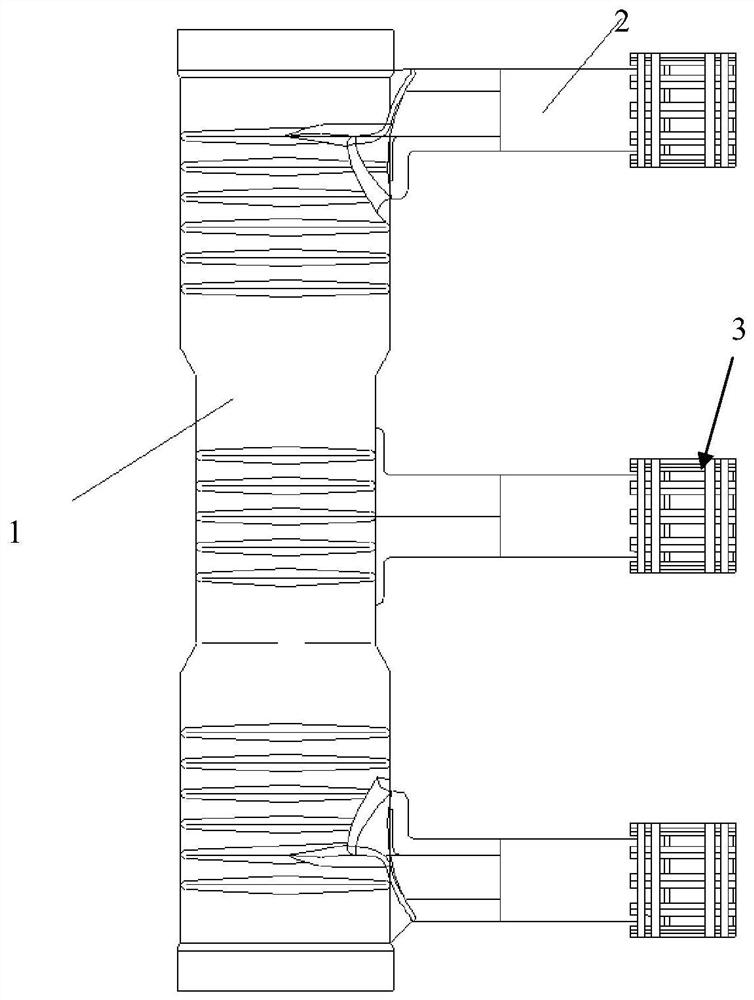

[0024] As shown in the figure, the solid-sealed pole of this embodiment includes a pole body 1, and three side-extruded contact arms 2 are formed at intervals at both ends of the same side or different sides of the pole body and in the middle. Connecting terminals 3 are formed on each part, such as duckbill contacts, plum blossom village contacts, etc., and vacuum bubbles are respectively arranged in the pole bodies between two adjacent contact arms. That is, one solid-sealed pole contains two vacuum bubbles, and the pole body, the contact arm and the two vacuum bubbles are integrally cast. Action mechanisms matching the vacuum bubbles are respectively provided at both ends of the pole body, which are similar to the prior art. Preferably, in order to balance the insulation effect and volume, a creepage wall is provided at the connection between the contact arm and the pole body, wherein the vacuum bubbles are arranged axially along the pole body. Of course, in order to improv...

no. 2 Embodiment

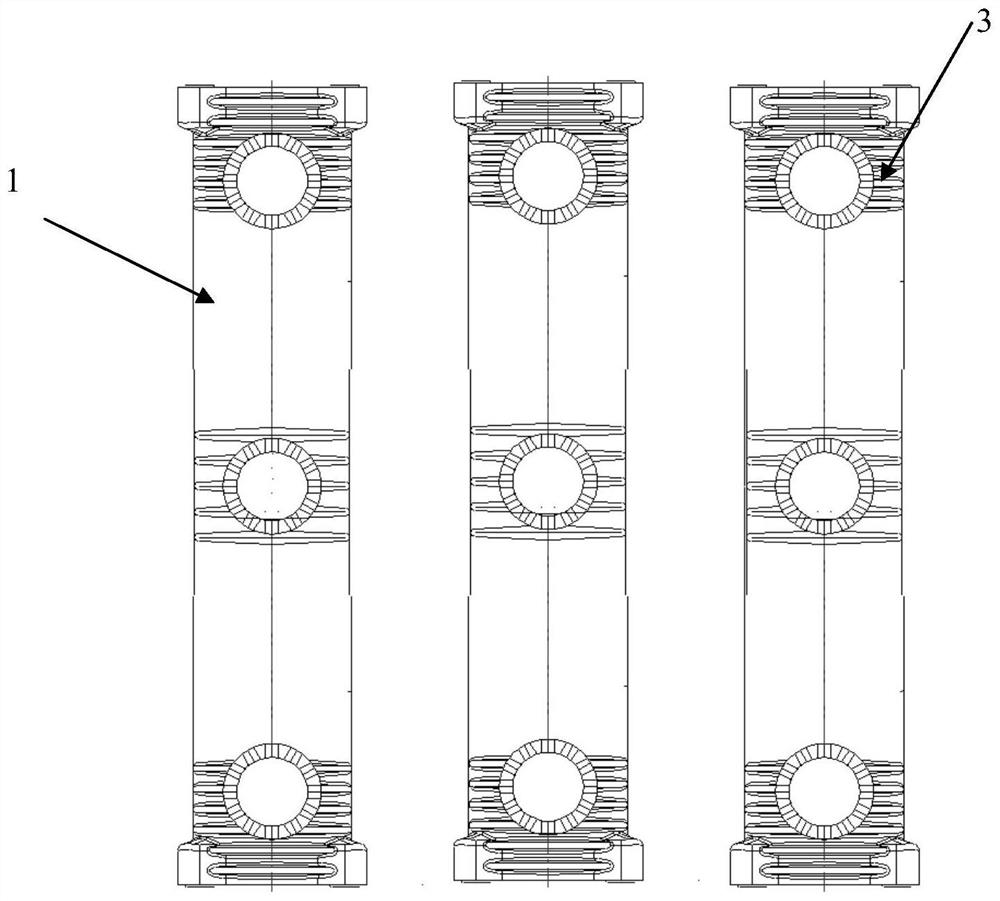

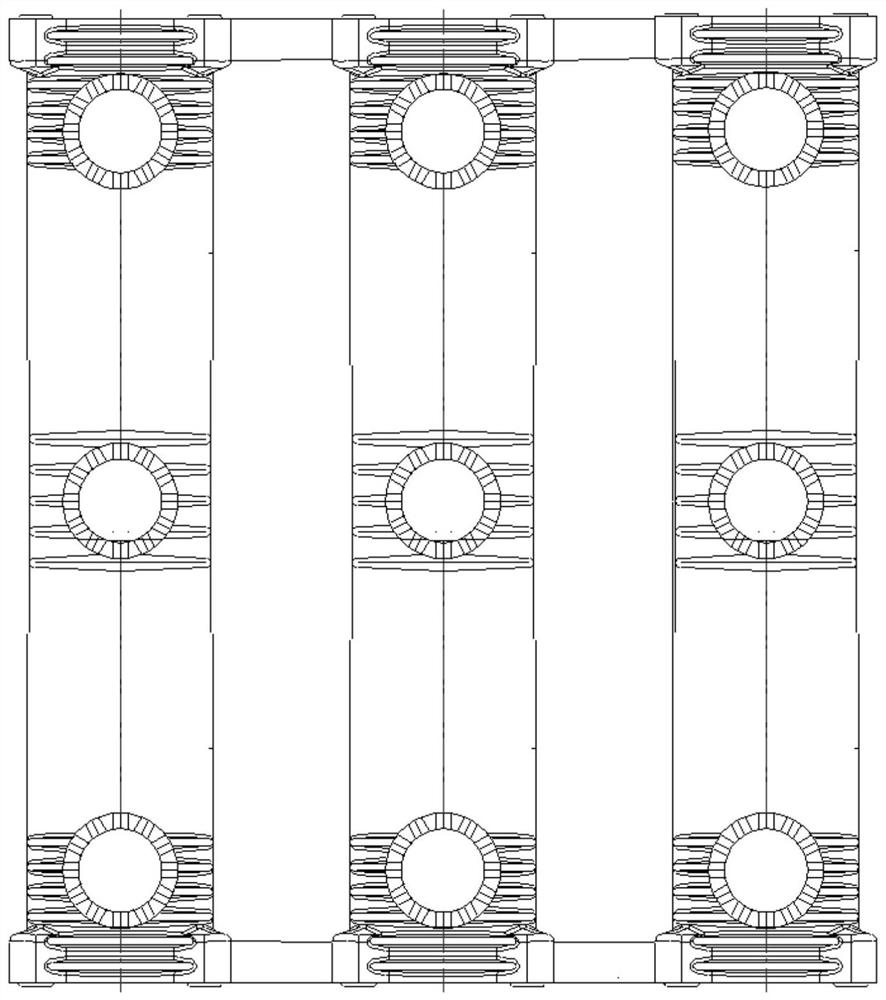

[0030] As shown in the figure, the solid-sealed pole set of this embodiment includes two terminal input pole groups 10 and three intermediate output contact arms 20. The integral column body 100 is one-to-one correspondingly formed on the terminal contact arm 101 on one side of the column body, one-to-one correspondingly formed on the terminal 102 at the end of the column body, such as a copper bar, and correspondingly arranged on the terminal contact arm and The vacuum bubble in the column body between the terminals, the vacuum bubble includes a vacuum bubble body and two terminals arranged therein, the terminals are respectively electrically connected to the terminal contact arm and the terminal, and the intermediate output contact The arm is arranged between the end input pole groups arranged adjacent to the two terminals, and the middle output contact arms are respectively electrically connected to the corresponding terminals of the two end input pole groups, and the ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com