Stator winding structure and motor

A stator winding and fixed structure technology, applied to the shape/style/structure of the winding conductor, can solve the problems of increasing the bearing distance, increasing the axial distance of the motor, and the small critical speed of the rotor, so as to reduce the volume and increase the speed , to ease the effect of the critical speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

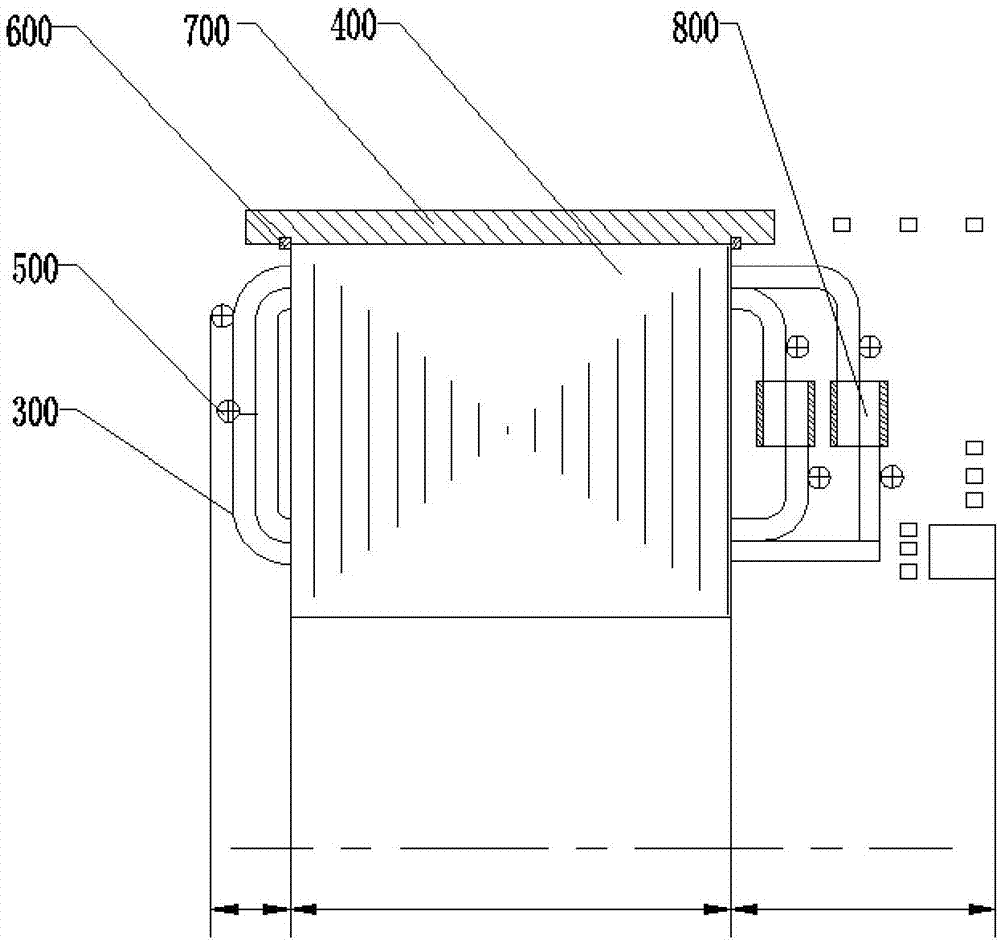

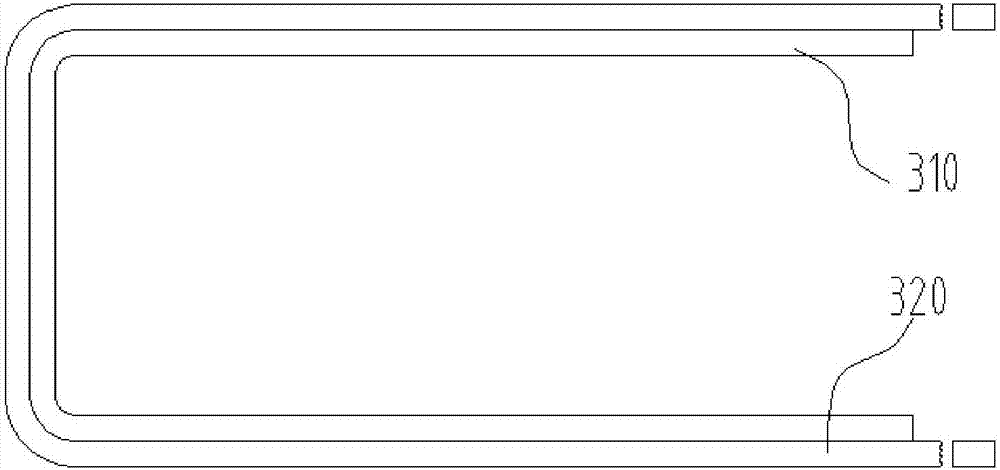

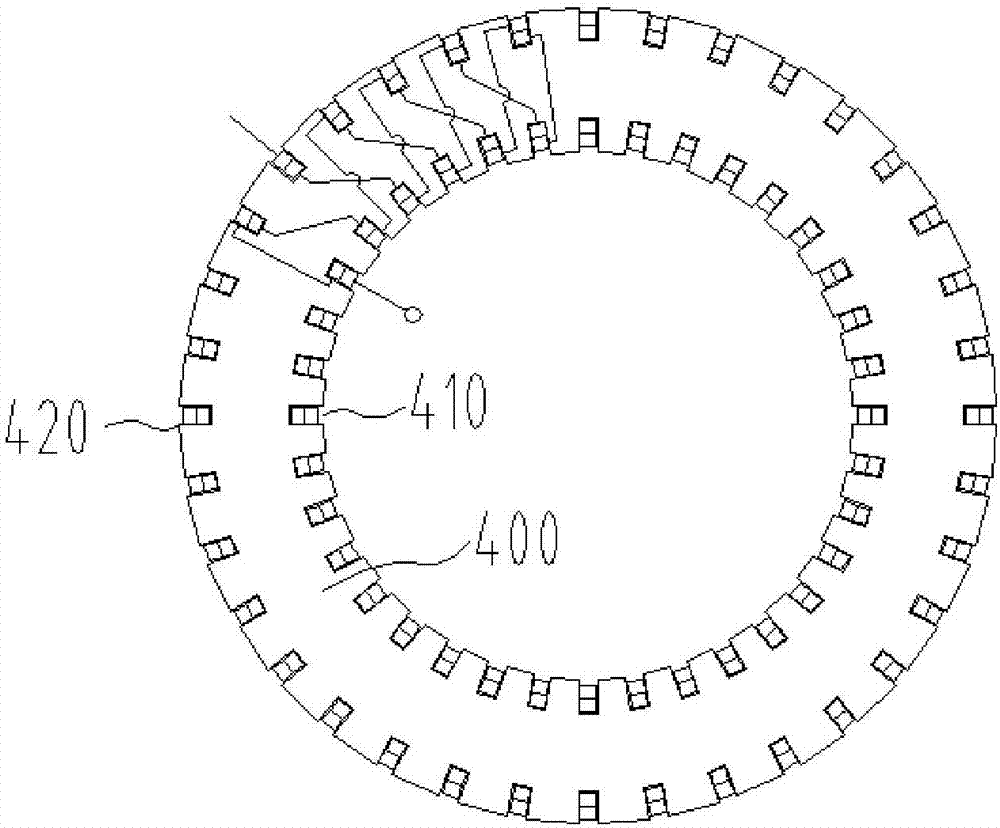

[0036] Such as Figure 1-Figure 3 As shown, the stator winding structure provided by this embodiment includes a stator core, a stator coil 300, and a fixing structure 500 for fixing the stator coil 300 on the side wall of the stator core; the stator coil 300 is arranged as a U-shaped structure, and can be The iron core 400 is inserted into and penetrates the side wall of the stator iron core 400 in the length direction; multiple sets of stator coils 300 are provided, and one end of any adjacent two sets of stator coils 300 is connected by a joint 800; the winding method of the stator coil 300 is to pass through the stator iron core The inner diameter of 400 to the outer diameter of the stator core 400 includes the stator core 400.

[0037] In this embodiment, the U-shaped stator coil 300 includes a first side and a second side opposite to the first side; the first side and the second side of the stator coil 300 are respectively bent by 90°, And it is connected with the bent f...

Embodiment 2

[0050] The motor provided in this embodiment includes the above-mentioned stator winding structure.

[0051] The motor provided in this embodiment includes the above-mentioned stator winding structure. Due to the setting of the stator winding structure, the motor has all the advantages of the above-mentioned material distribution mechanism, which can alleviate the technical problems that the end of the winding is too long, the axial distance of the motor is increased, and the critical speed of the rotor is reduced; the invention improves the motor speed. speed, reduce the size of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com