Rotation lock structure used for car seat

A car seat and rotary lock technology, which is applied in the field of rotary locks, can solve the problems of heavy rotary lock mechanism and many parts, and achieve the effect of reducing weight, reducing cost and reducing the risk of not locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

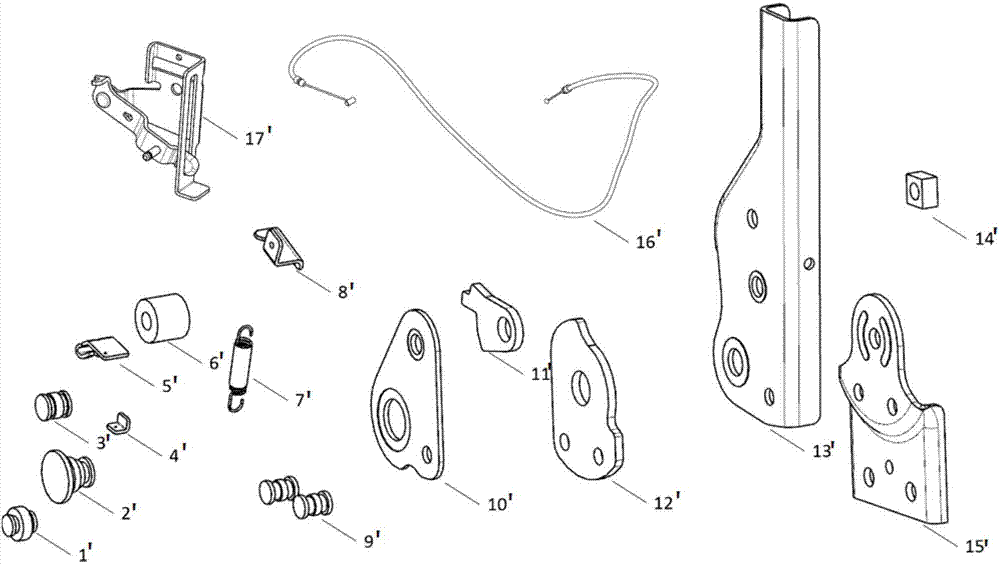

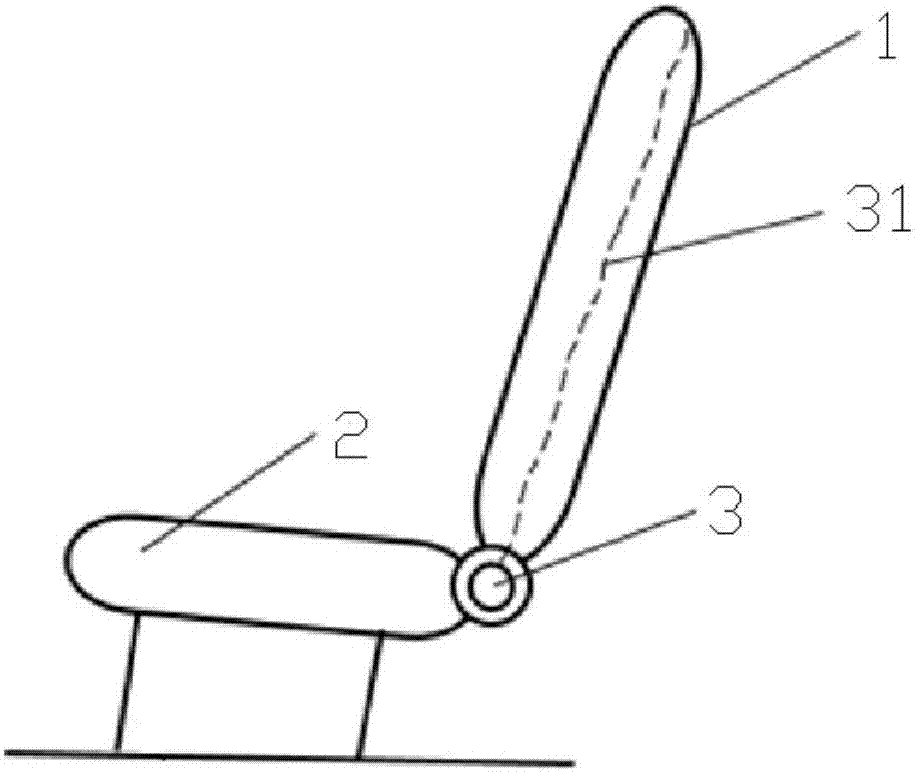

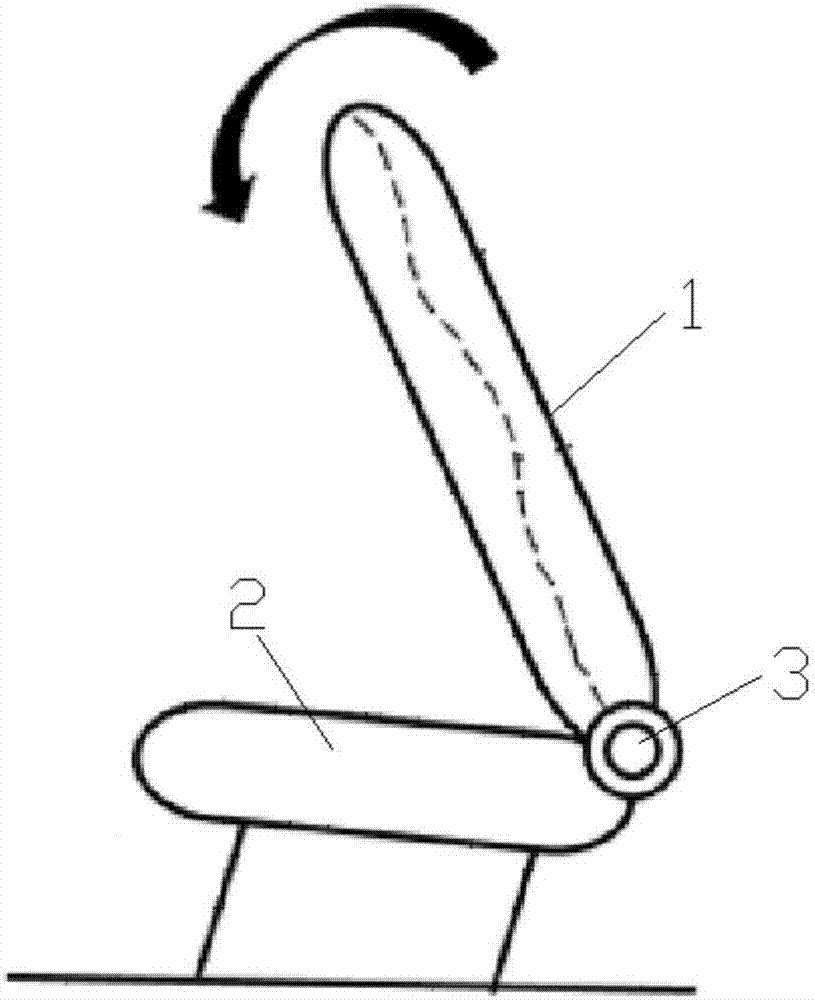

[0042] refer to Figure 2-6 As shown, the rotary lock structure for the car seat of the present invention, the car seat includes a backrest 1 and a seat cushion 2, the backrest 1 and the seat cushion 2 are rotationally connected by a rotary lock 3, and the rotary lock 3 includes a zipper mechanism 31, a lower bracket plate 32 , the upper bracket plate 33 and the rotary lock body 34, the lower bracket plate 32 is connected with the seat cushion 2, and the upper bracket plate 33 is connected with the backrest 1, wherein the rotary lock body 34 includes a cover plate 341, a guide plate 342, a pull rod 343, a lock plate 344, spring 345 and tooth plate 346;

[0043] The inside of the guide plate 342 is provided with a chute 347 and a mounting groove 348 which communicate with each other, the locking plate 344 is set in the chute 347, the spring 345 is set in the mounting groove 348, and the spring 345 is also in contact with the locking plate 344;

[0044] Tooth plate 346 fits on ...

Embodiment 2

[0062] The difference between the second embodiment and the first embodiment is:

[0063] refer to Figure 11-17 As shown, the bottom of the seat cushion 2 is also provided with a support rod 4, the support rod 4 is rotationally connected with the seat cushion 2, the cable switch 312 is arranged in the support rod 4, and the locking groove 349 includes a third locking groove 3493, when the support rod 4 When turning over, the cable switch 312 pulls the lock plate 344 through the cable 313 to retract to the inside of the chute 347, and the guide plate 342 can rotate relative to the tooth plate 346. When the support rod 4 is in use, the lock plate 344 moves along the radial direction. Slide outside the third locking groove 3493.

[0064] In this embodiment, the assembly process of the rotary lock body 34 is simpler, and only one welding process is required to complete the assembly. Specifically, after the cover plate 341, the guide plate 342, the pull rod 343, the lock plate 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com