Installing vehicle for large concrete components

A technology for concrete and installation vehicles, which is applied in the direction of transportation and packaging, trolley cranes, cranes, etc. It can solve the problems of low installation efficiency and incomplete guarantee of installation quality, so as to improve installation efficiency, facilitate on-site laying, and smooth installation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

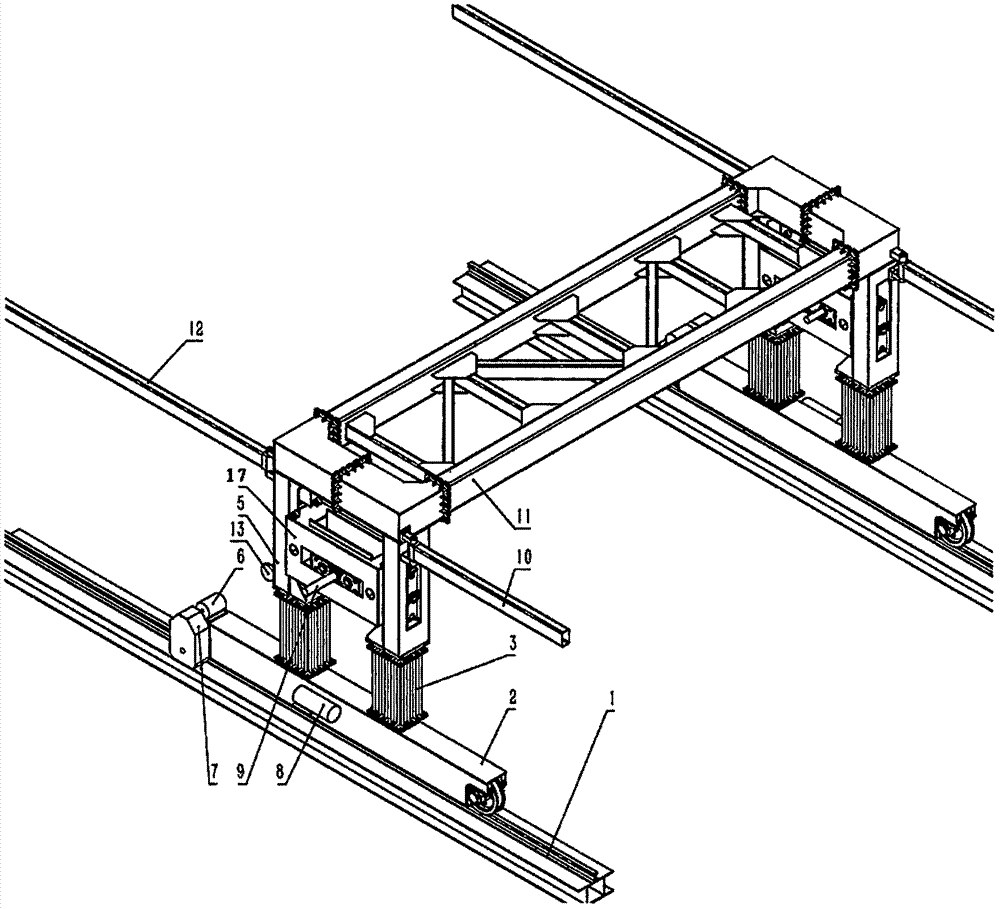

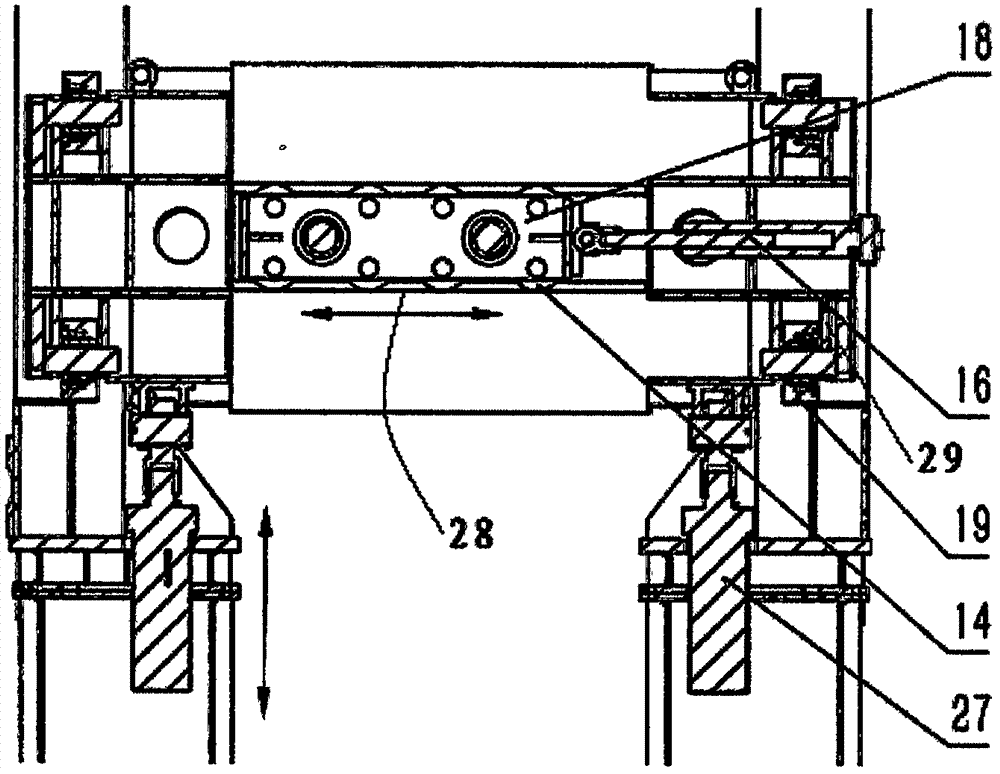

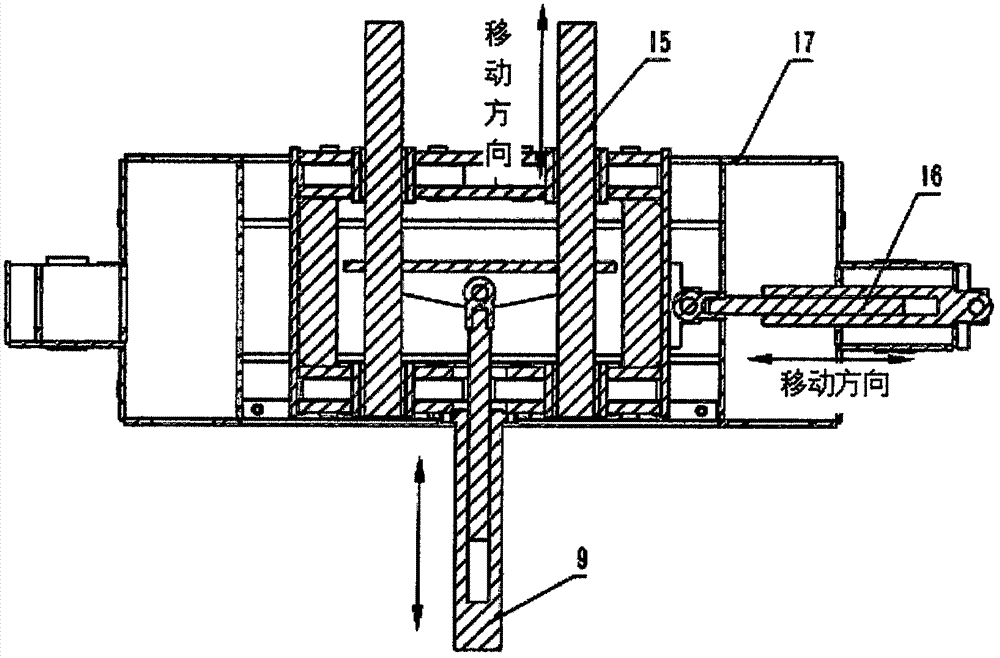

[0030] like figure 1 As shown, there is a door-shaped walking frame and a walking track 1, and the walking frame can move longitudinally on the walking track 1; the walking frame is composed of a transverse frame 11 and a leg 5, and the leg 5 is located below the transverse frame 11. Four outriggers are arranged below the horizontal support, and the four outriggers are arranged laterally and symmetrically in pairs. like figure 1 , figure 2 , image 3 As shown, a hydraulic three-dimensional adjustment device is provided at the corresponding outrigger position of the traveling frame, and two hydraulic three-dimensional adjustment devices are provided, and each hydraulic three-dimensional adjustment device is located between two outriggers on the same side in the Y direction. The hydraulic three-dimensional adjustment device includes a telescopic pin 15 , a first hydraulic cylinder 9 , a second hydraulic cylinder 16 , and a third hydraulic cylinder 27 . The telescopic pin sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com